Manufacturing method of electron emitter, electron source and image formation equipment

A technology of electron emission and manufacturing method, which is applied in the manufacture of discharge tubes/lamps, electrode systems, ships or lead wires, etc. It can solve the problems of electron beams not converging, poor image display performance, and substrate cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

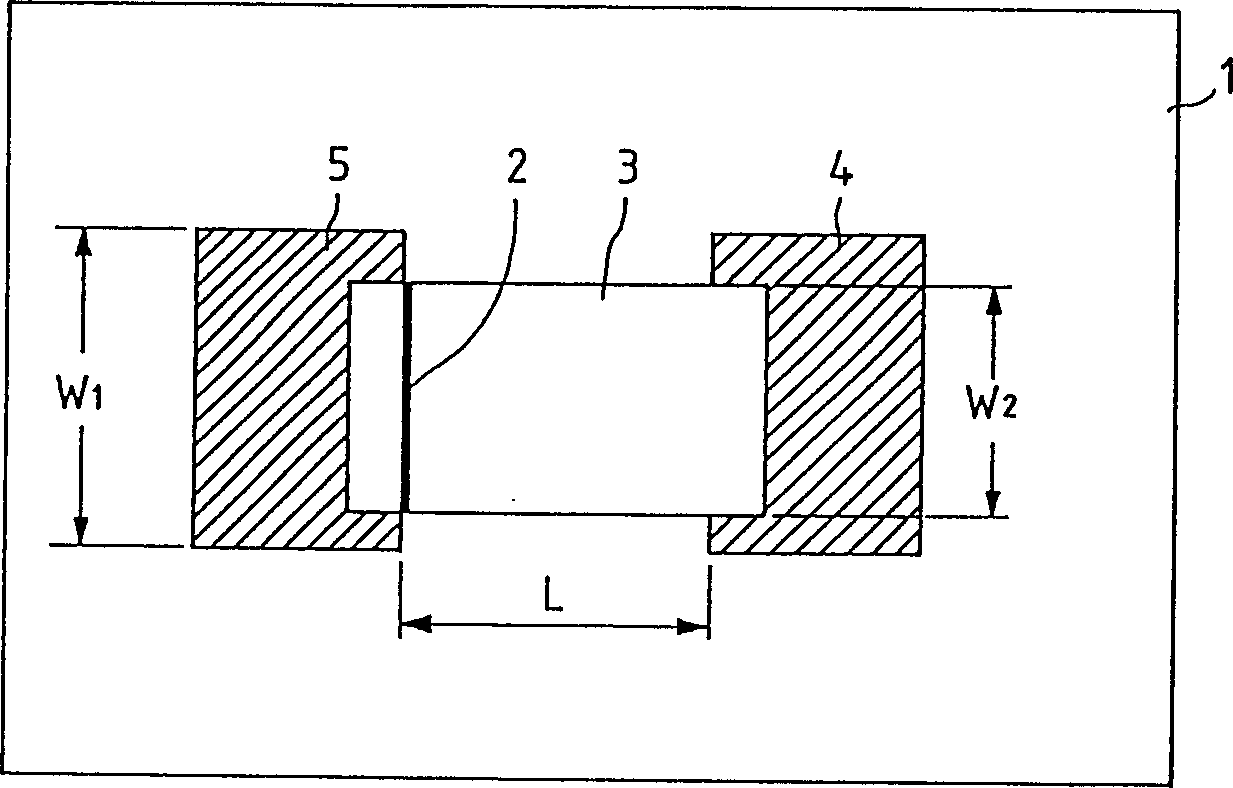

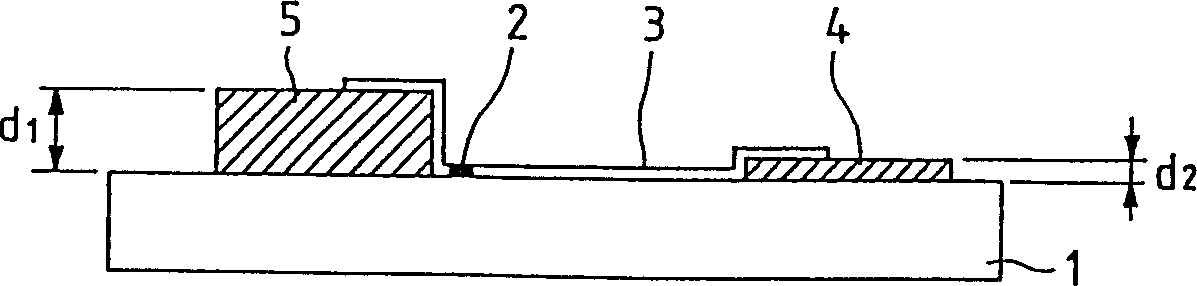

[0100] This embodiment is designed to show how Figure 1A and 1B Schematic illustration of the first basic structure. Note: Reference numerals 1, 2, and 3 denote the substrate, electron-emitting region, and conductive film including the electron-emitting region, respectively, and numerals 4 and 5 represent device electrodes.

[0101] Materials that can be used as the substrate 1 include quartz glass, glass containing a low concentration of impurities such as Na, and soda-lime glass on which a SiO 2 Layers, ceramic substances such as alumina and Si can constitute a glass substrate.

[0102] Although the opposite device electrodes 4 and 5 can be made of any highly conductive material, preferred materials include metals (such as: Ni, Cr, Au, Mo, W, Pt, Ti, Al, Cu, and Pb) and their Alloys from Pb, Ag, RuO 2 , Pd-Ag and metals or metal oxides selected from glass can be printed conductive materials, transparent conductive materials (such as In 2 o 3 -SnO 2 ), and semiconduct...

Embodiment 2

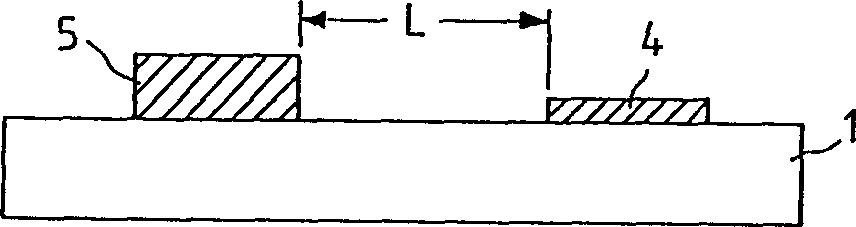

[0133] The second basic structure of the surface conduction type electron-emitting device according to the present invention will now be described.

[0134] in having Figure 4A and 4B In the surface conduction type electron-emitting device of the second basic structure shown, an electron-emitting region is formed adjacent to any one of a pair of device electrodes 4 and 5, and the heights of the respective stepped portions of the device electrodes 4 and 5 are equal to each other.

[0135] Such as Figure 4A and 4B As shown, a conductive thin film 3 is formed on a device electrode 5 and below another device electrode 4 . Therefore, only a step is produced on the device electrode 5 on the conductive film, and thus an electron-emitting region 2 is formed after the energization forming process at a position close to the device 5 .

[0136] As described above with reference to the first embodiment, the relationship between the height of the device electrode 5 and the conductive...

Embodiment 3

[0145] In the surface conduction type electron-emitting device according to the present invention, any one of the pair of device electrodes (in the Figure 1A and 1B An electron emission region 2 is formed at the position of the device electrode 5). Such an electron-emitting region 2 can be produced by any one of the first and second manufacturing methods according to the present invention, which will be described in more detail below.

[0146] Refer below Figures 2A to 2C described as Figure 1A and 1B Said surface conduction type electron-emitting device according to the present invention, Figures 2A to 2C Such devices are represented at different fabrication steps.

[0147] 1) After the substrate 1 is thoroughly cleaned with detergent and pure water, a material is deposited on the substrate 1 by vacuum deposition, sputtering, or some other suitable technique to obtain a pair of device electrodes 4 and 5, The device electrodes 4 and 5 are then produced by photolithog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com