Cleaning mechanism of copper foil crude foil engine

A technology of cleaning mechanism and foil machine, which is applied in the direction of cleaning method using gas flow, cleaning method and utensils, electroforming, etc., can solve the problems of wasting water, affecting the surface quality of copper foil, and high cost, and achieves the goal of ensuring production quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

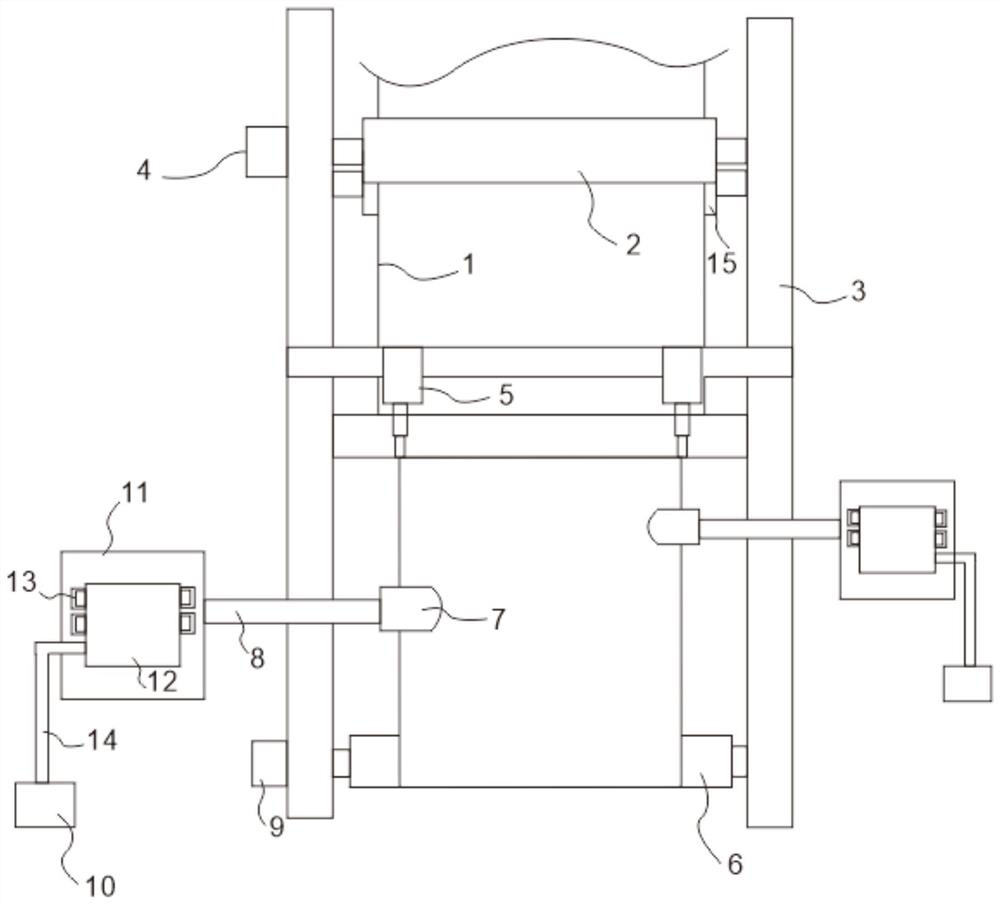

[0024] A cleaning mechanism of a copper foil raw foil machine, which includes a frame 3, a copper foil peeling roller, a copper foil winding roller 6, a trimming mechanism 5 and a cleaning mechanism. The copper foil peeling roller includes a rotating installation on the front of the frame. The driving roller 2 and the passive roller 15, in which the driving roller is driven by the driving roller motor 4 to rotate.

[0025] The trimming mechanism is installed at the rear of the copper foil peeling roller, and the winding roller is rotatably installed at the rear of the frame, and the winding roller is driven and rotated by the winding roller motor 9 .

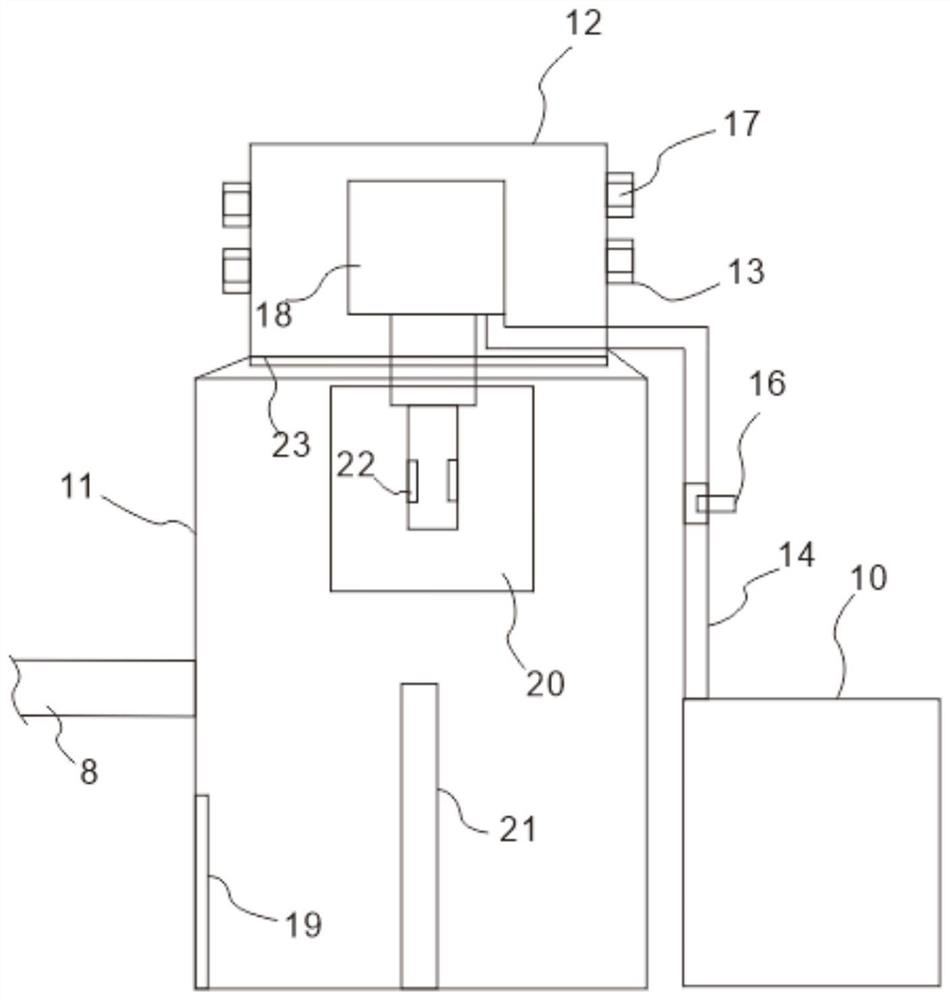

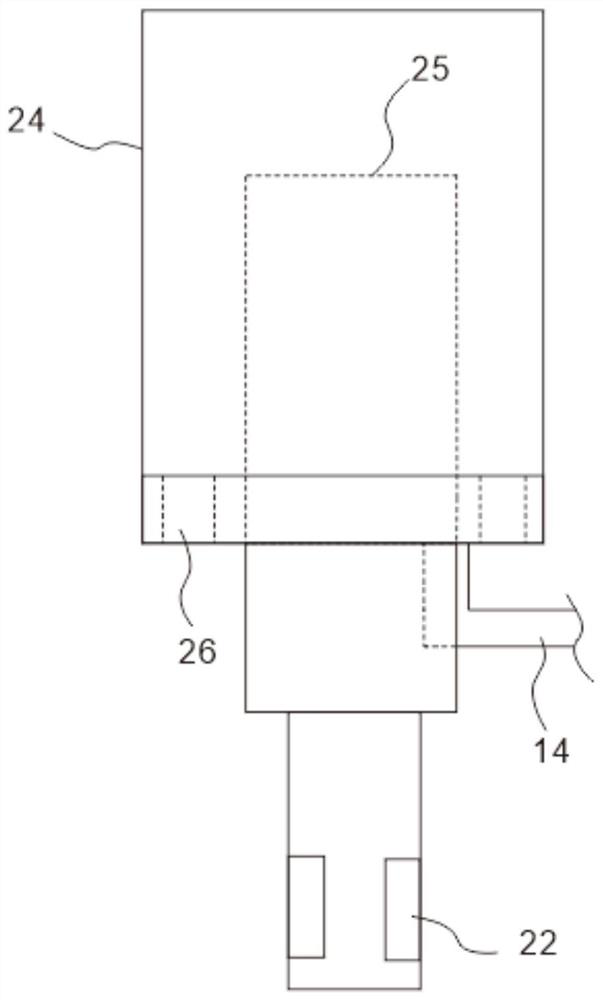

[0026] Two sets of cleaning mechanisms are provided on both sides of the copper foil. Each set of the cleaning mechanisms includes a collection tank, an air compressor 10 and a suction nozzle 7. The collection tank includes a tank body 11, a venturi assembly 18 and a negative pressure generating head 12. , the side wall of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com