Semiconductor light emitting element

A technology of light-emitting elements and semiconductors, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., and can solve the problems of inability to inject light-emitting elements and fully luminous light-emitting elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

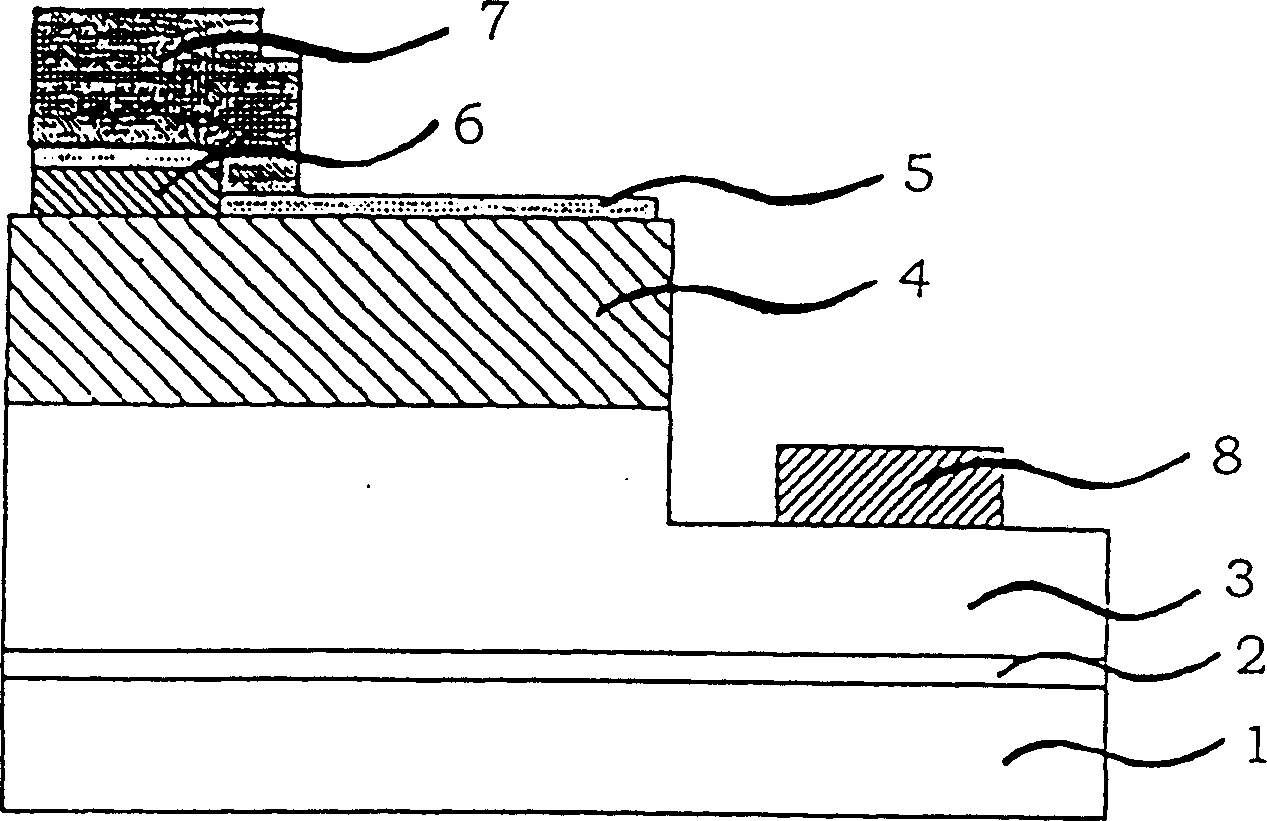

[0040] 1( a ) and ( b ) show the electrode structure of the gallium nitride-based compound semiconductor light-emitting device of the present invention.

[0041] This light-emitting device is a p-type gallium nitride that forms a light-emitting surface by sequentially stacking a buffer layer 2, an n-type gallium nitride-based compound semiconductor layer 3, and a p-type gallium nitride-based compound semiconductor layer 4 on an insulating substrate. A current blocking layer 6 and a light-transmitting electrode 5 are formed on the compound semiconductor layer 4, and a pad electrode 7 having an electrode connection portion connected to the light-transmitting electrode 5 is formed on the current blocking layer 6. The n-type gallium nitride-based compound semiconductor An n-type electrode 8 is formed on layer 3 .

[0042] Next, a method of manufacturing the above-mentioned light-emitting element will be described.

[0043] First, an AlGaN buffer layer 2 , an n-type gallium nitrid...

Embodiment 2

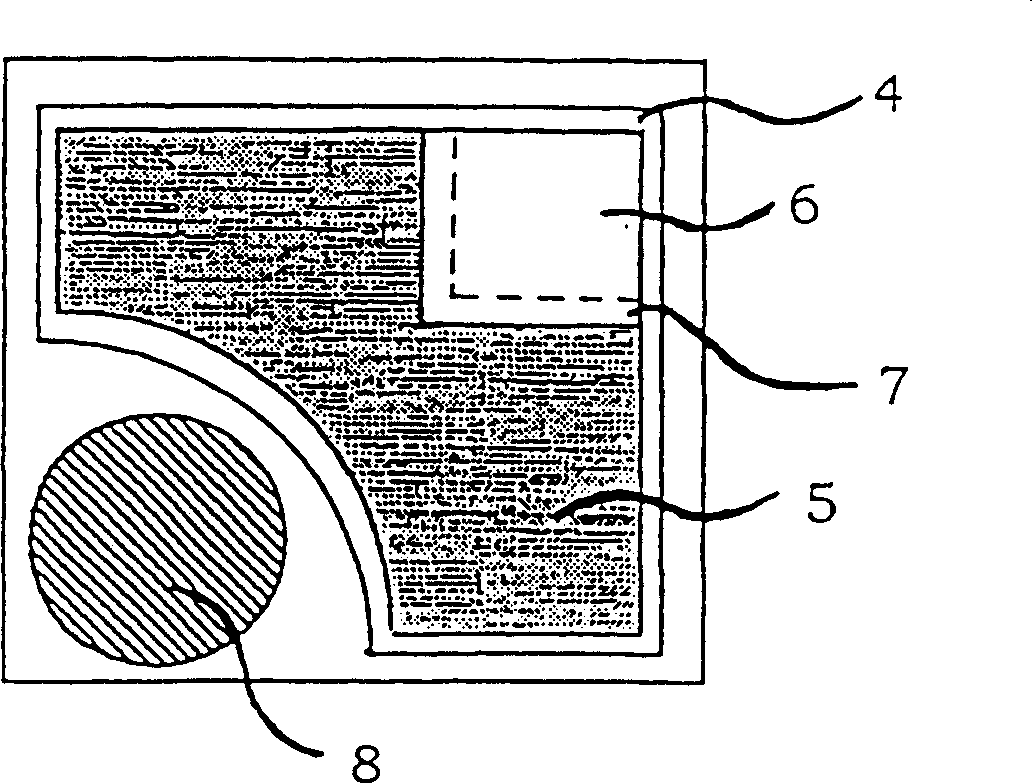

[0053] Another GaN-based compound semiconductor light-emitting element of the present invention is shown in figure 2 .

[0054] This light-emitting element is formed by sequentially laminating an AlGaN buffer layer 2, a p-type gallium nitride-based compound semiconductor layer 4, and an n-type gallium nitride-based compound semiconductor layer 3 on an insulating substrate 1 to form an n-type nitrogen oxide layer on the light-emitting surface. A current blocking layer 6 made of silicon nitride, a light-transmitting electrode 5 made of titanium, and a pad electrode 7 are formed on the gallium-based compound semiconductor layer 3 .

[0055] A method of manufacturing such a light-emitting element will be described below.

[0056] First, an AlGaN buffer layer 2 , a p-type gallium nitride-based compound semiconductor layer 4 , and an n-type gallium nitride-based compound semiconductor layer 3 are stacked on a sapphire substrate 1 .

[0057] Next, a silicon nitride current blockin...

Embodiment 3

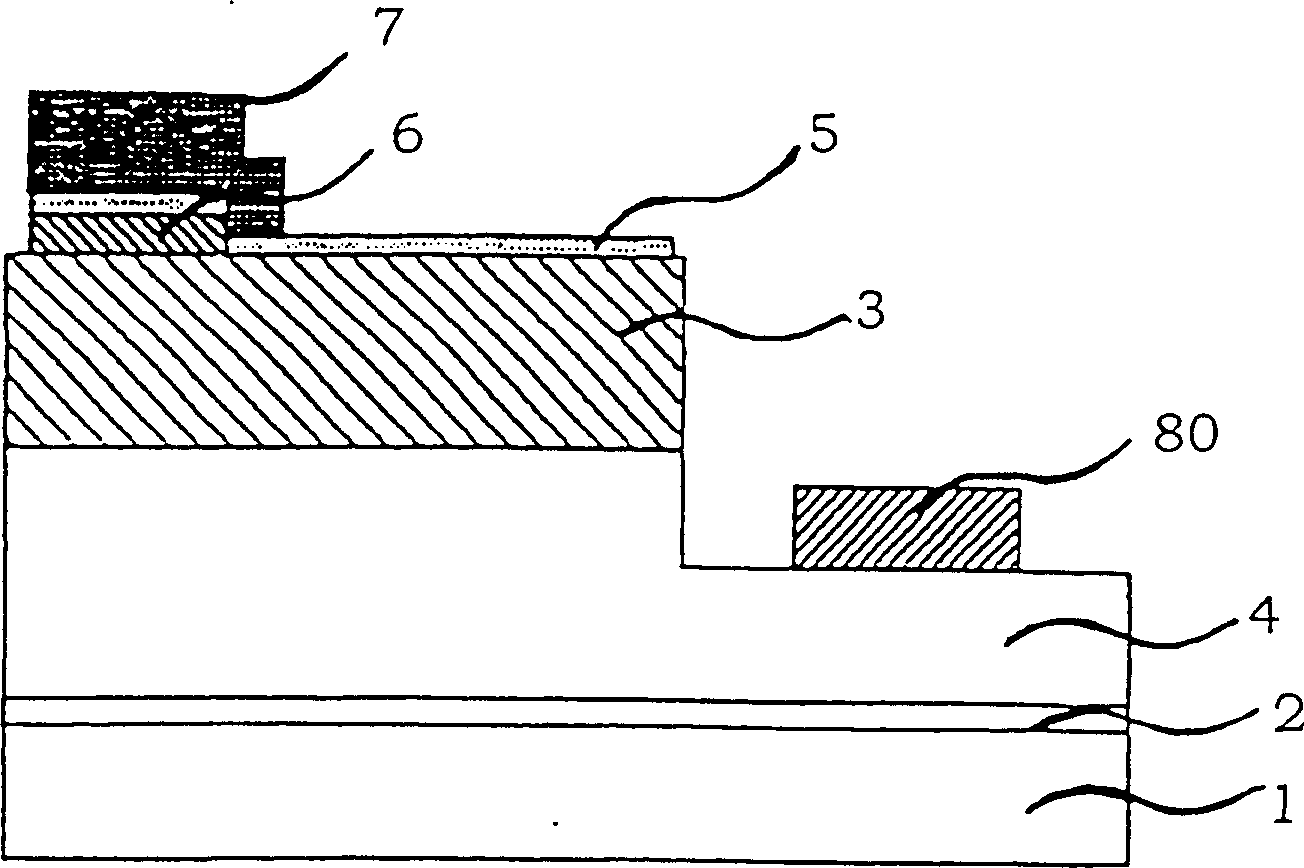

[0065] 3( a ) and ( b ) show yet another gallium nitride-based compound semiconductor light-emitting device of the present invention.

[0066] In Example 3, the n-type gallium nitride-based compound semiconductor layer 3 and the p-type gallium nitride-based compound semiconductor layer 4 are sequentially stacked on the n-type conductive substrate 60 to form the p-type gallium nitride-based compound semiconductor layer 4 on the light emitting surface. A current blocking layer 6 made of titanium oxide and a light-transmitting electrode 5 are formed on the compound semiconductor layer 4, and a pad electrode 7 having an electrode connection portion in contact with the light-transmitting electrode 5 is formed on the upper surface of the current blocking layer 6 and its peripheral portion, An n-type electrode 8 is also formed on the back surface of the n-type conductive substrate 60 .

[0067] Next, a method of manufacturing the above-mentioned light-emitting element will be describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com