Double-layer straight tube heat exchange tube for liquid metal cooling reactor

A technology of liquid metal cooling and heat exchange tubes, applied in the field of heat exchange tubes, can solve problems affecting the economy and safety of reactors, complex structures, etc., reduce the probability of rupture accidents, simplify structural design, and enhance convective heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

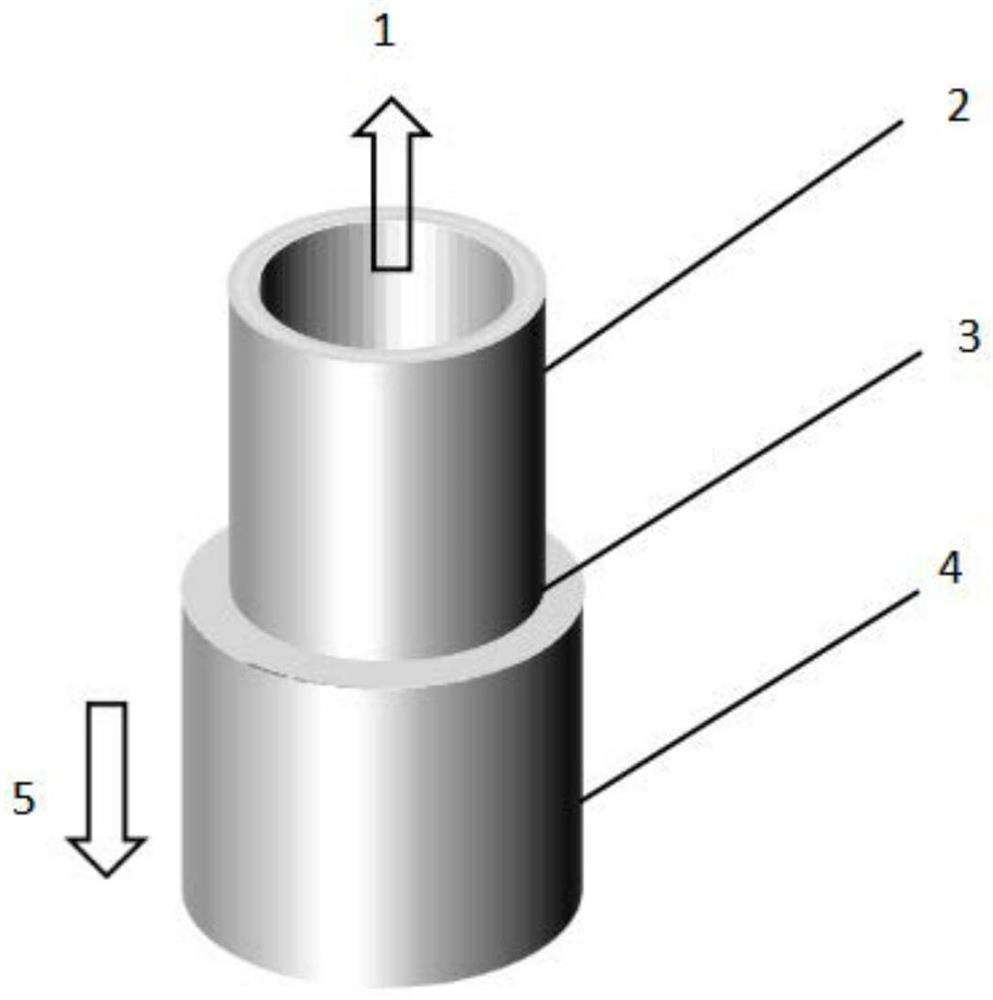

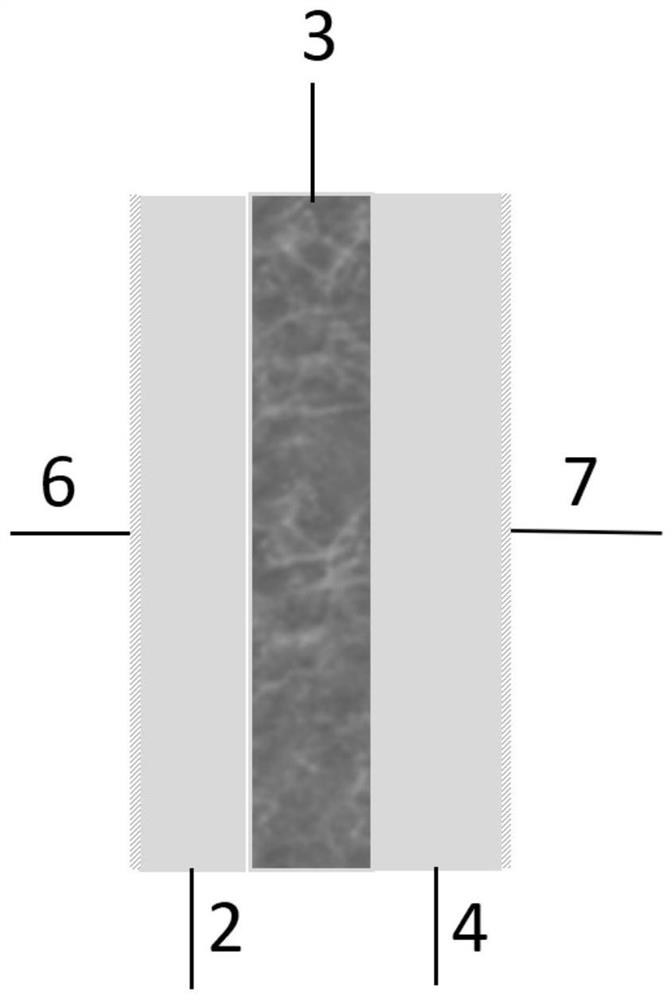

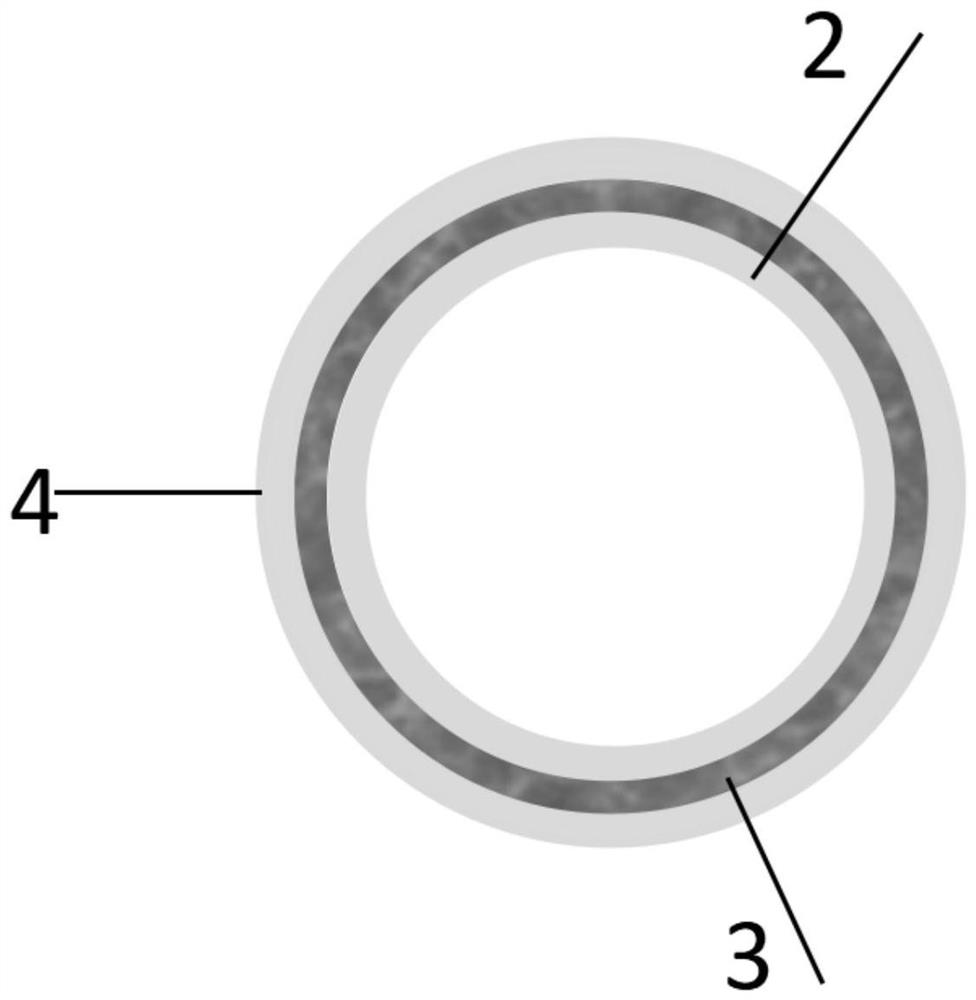

[0021] The present invention provides a double-layer straight-tube heat exchange tube for a liquid metal cooling reactor. The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings:

[0022] figure 1 , figure 2 It is a schematic diagram of a partial structure and an enlarged schematic diagram of a partial gap of a double-layer straight-pipe heat exchange tube for a liquid metal cooling reactor of the present invention. The double-layer straight-tube heat exchange tube of the present invention includes an inner tube 2 formed by a graphene-doped multi-layer graphene / 316L composite material for the entry and flow of the secondary circuit coolant 1, and an inner tube 2 tightly combined with the inner tube 2. Outer tube 4 of graphene-doped multilayer graphene / 316L composite. Wherein, the inner wall of the inner tube 2 is coated with the first graphene nano anti-corrosion coating 6 and the outer wall of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com