Evaporator based on high-permeability high-capillary-force multi-scale capillary core

A technology of high capillary force and evaporator, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of high thermal conductivity, small heat transfer limit, small capillary suction, etc., achieve good contact, reduce flow resistance, reduce The effect of heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

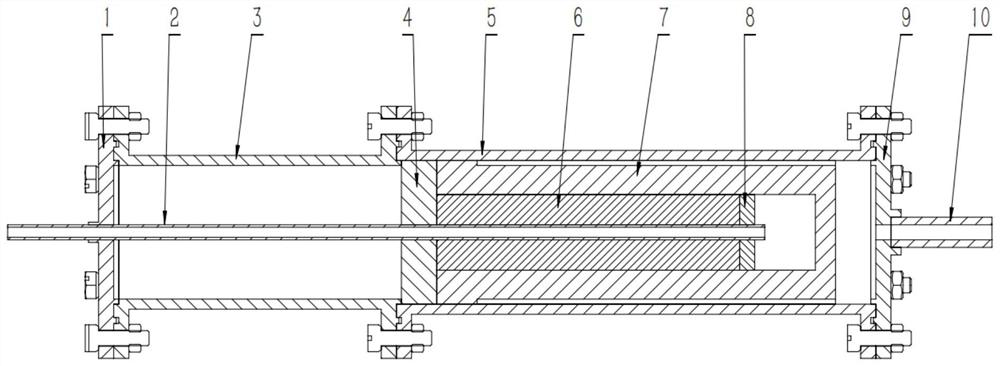

[0030] In conjunction with the accompanying drawings, the structural principle of the present invention will be described in further detail below.

[0031] For the novel evaporator of the present invention, refer to the appendix figure 1 , the structure of the present invention is mainly different from the conventional evaporator including:

[0032] The rear end cap 4, the secondary core 6, and the front end cap 8 are sealed.

[0033] The implementation effect of the present invention is that the capillary core structure uses sintered metal, sintered ceramics, etc. 0.5-3 micron small aperture capillary core as the main core to provide capillary force to enhance evaporation heat transfer; 200-600 mesh large aperture metal woven wire mesh is stacked A secondary core is formed for liquid introduction, while reducing flow resistance and heat leakage. Due to the use of the secondary core stacked by the wire mesh, the interference fit between the secondary core and the main core i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com