Waste glue discharging and cleaning device for building

A cleaning device and construction technology, applied in construction waste recycling, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of inability to cool down and condense in time, easy accumulation of waste rubber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

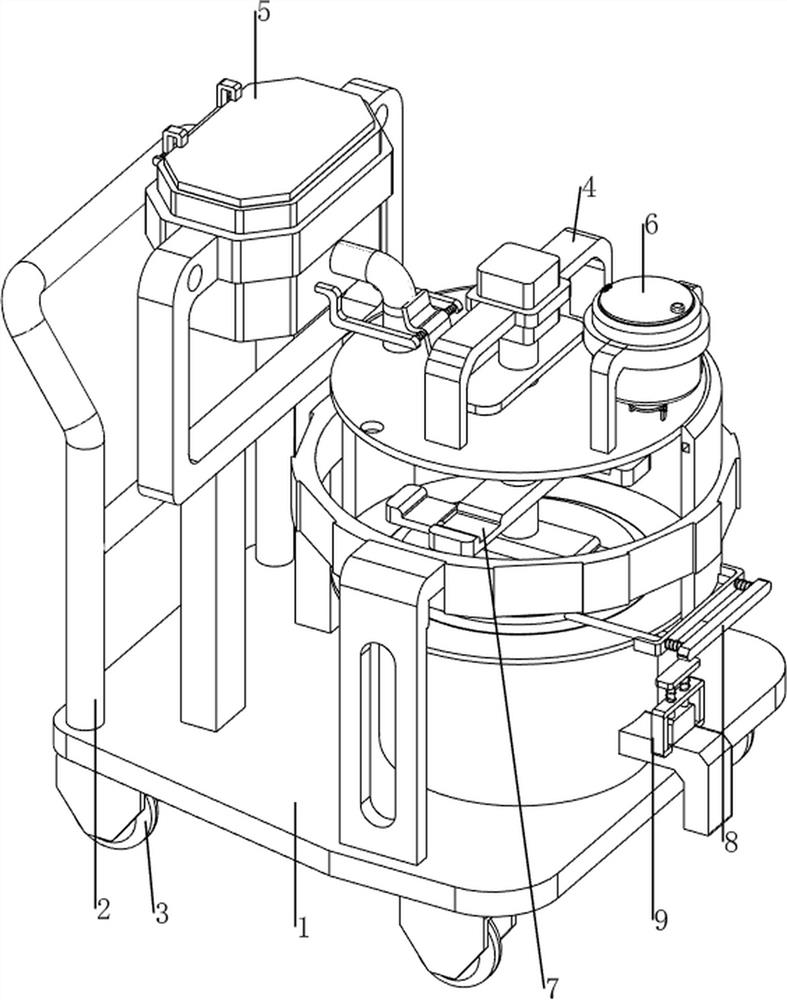

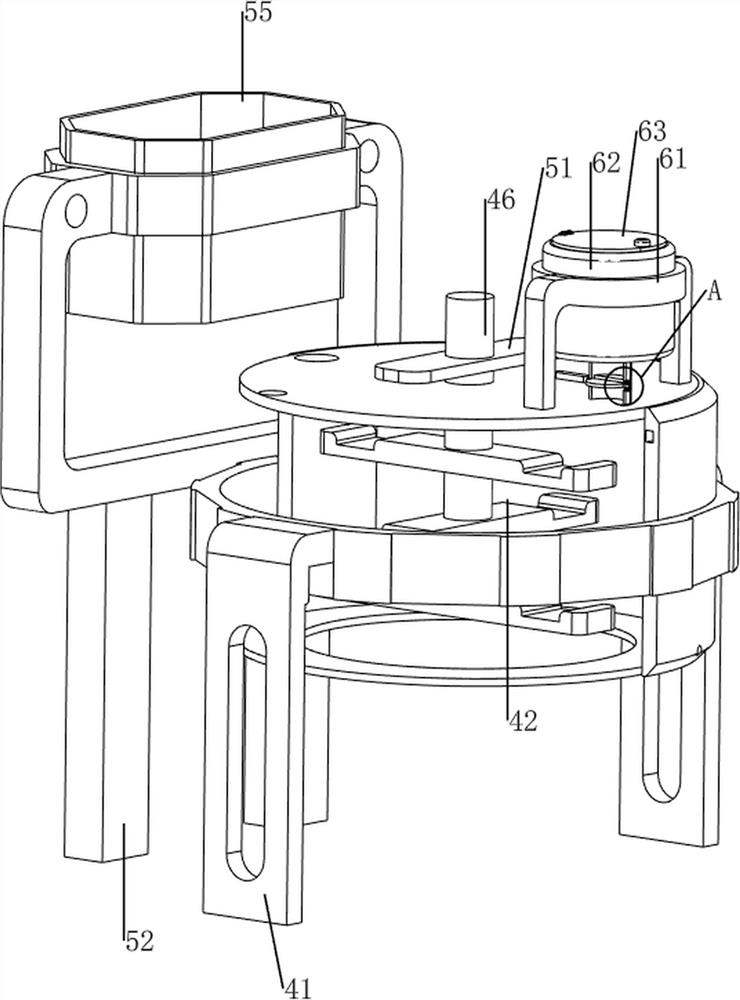

[0028] A construction waste glue discharge cleaning device, such as Figure 1-9 As shown, it includes a support plate 1, a first pull rod 2, a pulley 3, a stirring mechanism 4 and a blanking mechanism 5, a first pull rod 2 is provided on the left side of the top of the support plate 1, and the four corners of the bottom of the support plate 1 are rotationally connected There is a pulley 3 , a stirring mechanism 4 is arranged on the support plate 1 , and a feeding mechanism 5 is arranged between the support plate 1 and the stirring mechanism 4 .

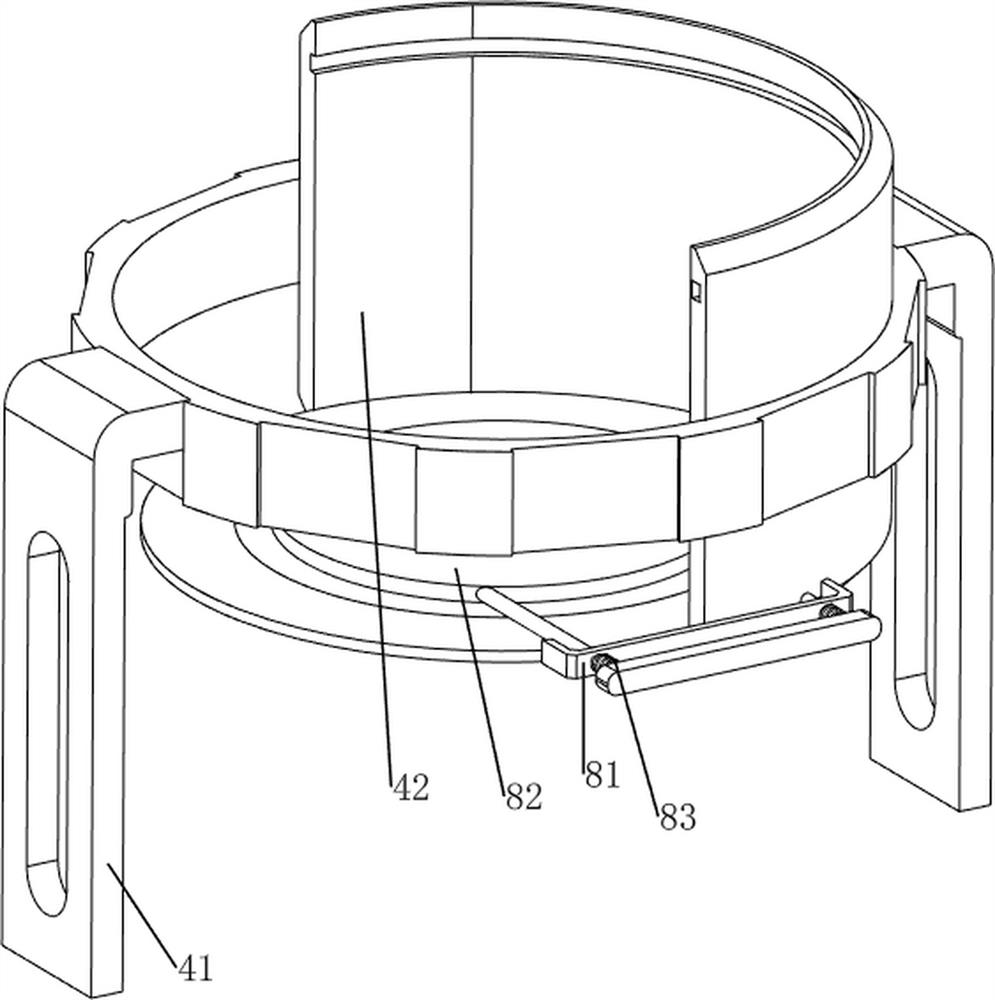

[0029] The stirring mechanism 4 includes a first support frame 41, a first lower material cylinder 42, a second lower material cylinder 43, a second support frame 44, a motor 45 and a stirring rod 46, and a first support frame is connected to the right side of the top of the support plate 1 41. The first support frame 41 is provided with a first lower material barrel 42, and the right side of the top of the support plate 1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com