Hole making device

A hole-making device and placing table technology, applied in positioning devices, manufacturing tools, boring/drilling and other directions, can solve the problems of dead corners in the operating range of the drilling mechanism, wear and scratches on the surface of parts, and reduce the flexibility of the device. Flexible and stable drilling, increasing accuracy, and improving the effect of drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

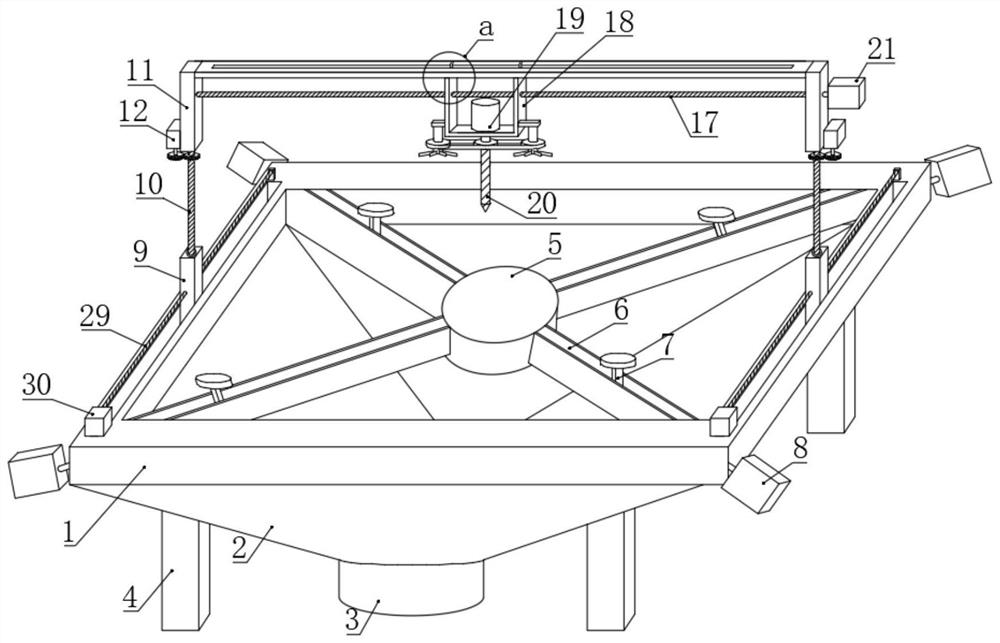

[0027] see attached drawings, refer to Figure 1-6 , a hole-making device for aircraft components, comprising a support frame 1, a collection bucket 2 is installed on the lower side wall of the support frame 1, a discharge pipe 3 is installed at the bottom end of the collection bucket 2, and the bottom of the collection bucket 2 is installed with four stand 4. The whole device is supported by the stand 4 .

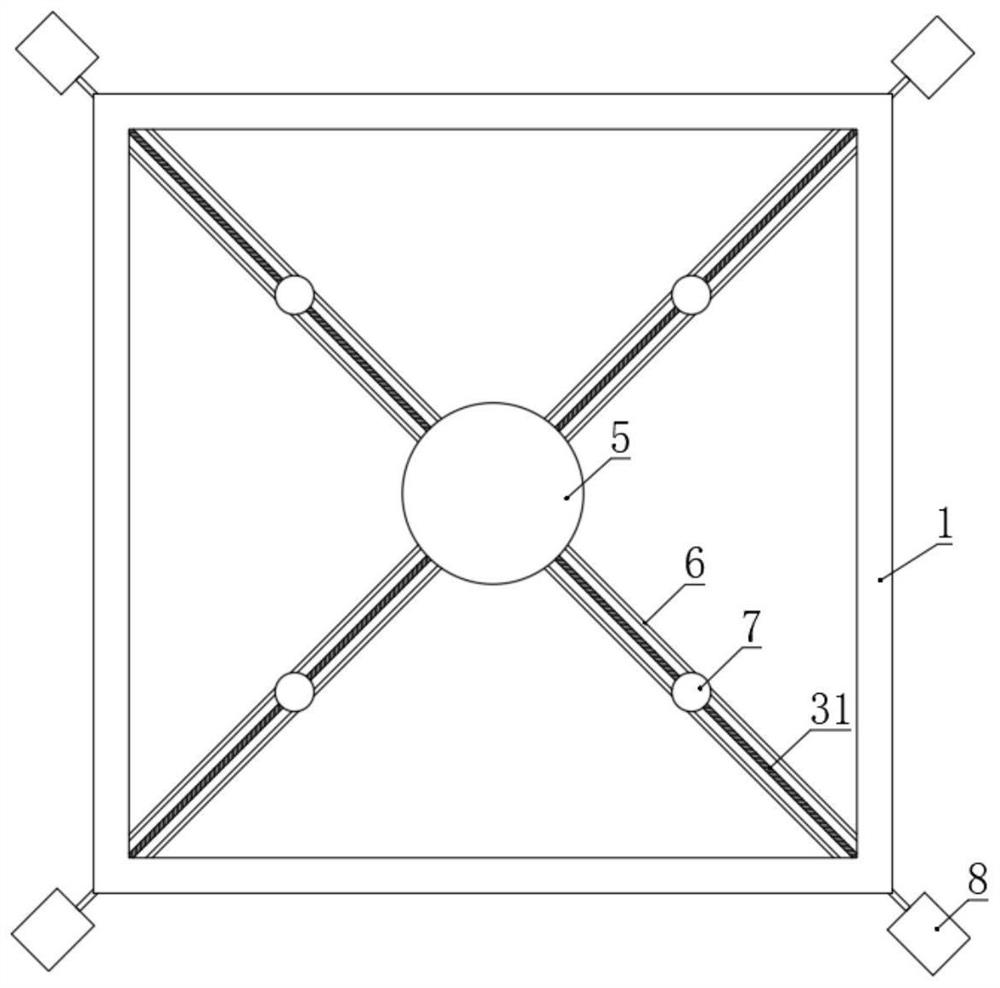

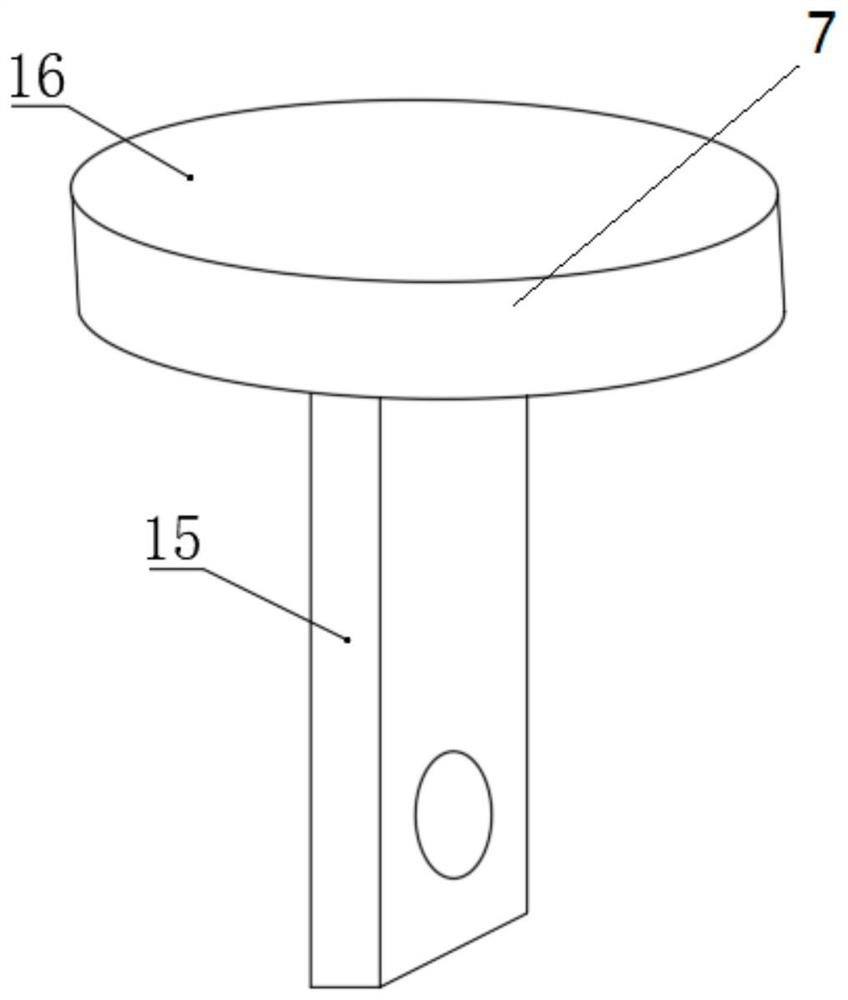

[0028] Four guide rails 6 are installed on the inner diagonal of the support frame 1, and one end of the four guide rails 6 close to the center of the support frame 1 is fixed with the placing table 5 together. The fourth threaded rod 31, the fourth threaded rod 31 is threadedly installed with the positioning pin 7, the four corners of the outer side of the support frame 1 are installed with the first motor 8, and the end of the fourth threaded rod 31 away from the placing table 5 is respectively connected with the first motor 8. The drive end of the motor 8 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com