Transfer manipulator for manufacturing optical glass

A technology of optical glass and manipulators, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve problems such as low transfer efficiency and glass damage, and achieve the effect of avoiding damage and shattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

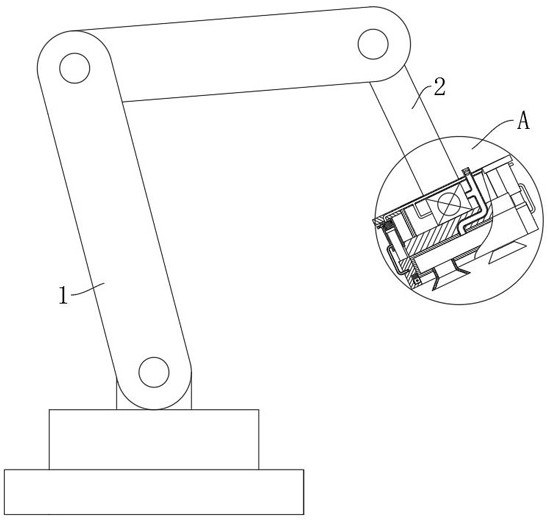

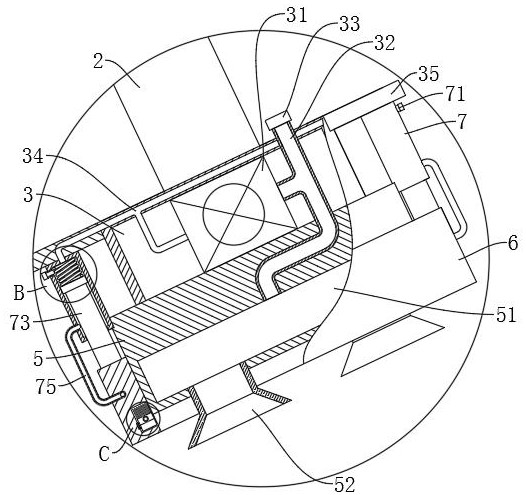

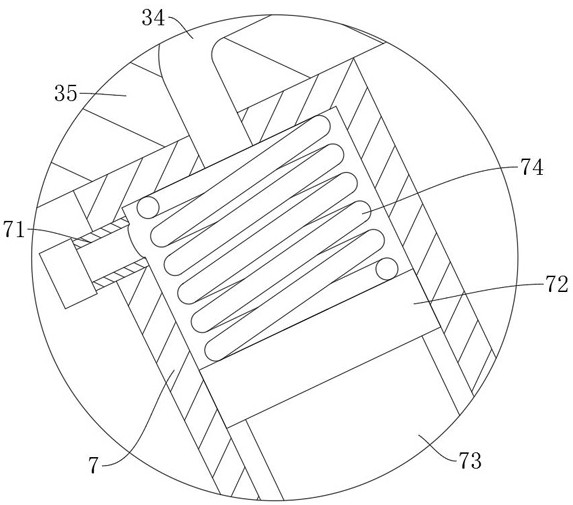

Embodiment 1

[0033] refer to Figure 1-Figure 8 , a transfer manipulator for manufacturing optical glass, comprising a manipulator 1 and a connecting rod 2 installed on the manipulator 1, and also comprising: a negative pressure cylinder 3 fixedly connected to the connecting rod 2, and the bottom of the negative pressure cylinder 3 is fixedly connected There is a bottom plate 5, the bottom of the bottom plate 5 is fixedly connected with a suction cup 52; the protection frame 6 is slidably connected on the bottom plate 5, the negative pressure cylinder 3 is fixedly connected with connecting blocks 35 on both sides, and the connecting block 35 is fixedly connected with a piston cylinder 7, the piston cylinder 7 is slidably connected with an ejector rod 73, and one end of the ejector rod 73 away from the piston cylinder 7 is fixedly connected to the protection frame 6; the negative pressure component is arranged in the negative pressure cylinder 3 to extract the air in the suction cup 52; it i...

Embodiment 2

[0036] refer to Figure 1-Figure 3 , Figure 5-Figure 6, a transfer manipulator for manufacturing optical glass, comprising a manipulator 1 and a connecting rod 2 installed on the manipulator 1, and also comprising: a negative pressure cylinder 3 fixedly connected to the connecting rod 2, and the bottom of the negative pressure cylinder 3 is fixedly connected There is a bottom plate 5, the bottom of the bottom plate 5 is fixedly connected with a suction cup 52; the protection frame 6 is slidably connected on the bottom plate 5, the negative pressure cylinder 3 is fixedly connected with connecting blocks 35 on both sides, and the connecting block 35 is fixedly connected with a piston cylinder 7, the piston cylinder 7 is slidably connected with an ejector rod 73, and one end of the ejector rod 73 away from the piston cylinder 7 is fixedly connected to the protection frame 6; the negative pressure component is arranged in the negative pressure cylinder 3 to extract the air in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com