Sludge transfer system and sludge transfer method based on same

A sludge and transfer vehicle technology, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment, etc., can solve problems such as environmental pollution and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The embodiment of the present application discloses a sludge transfer system.

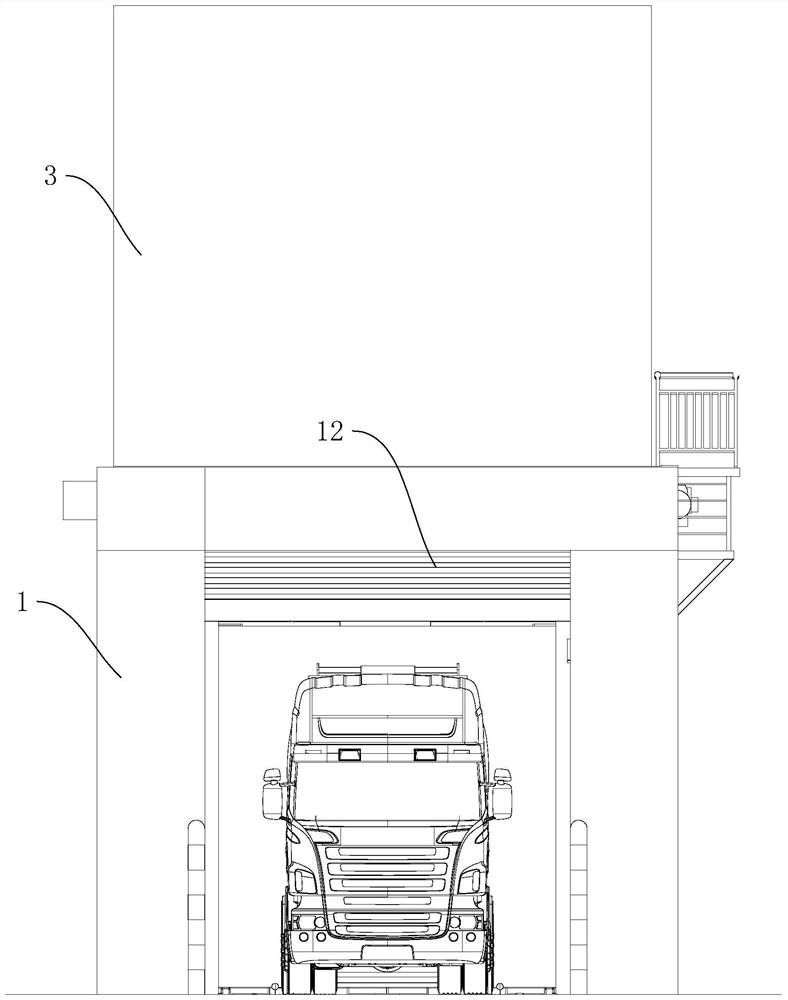

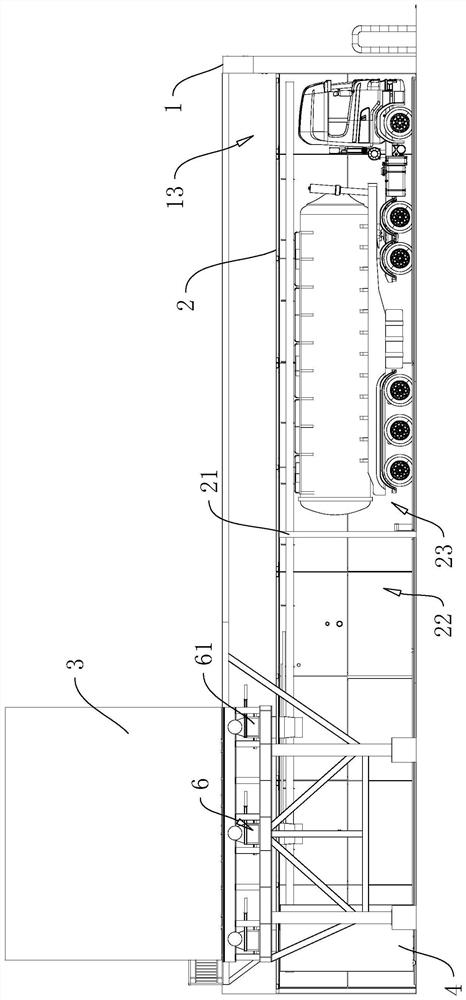

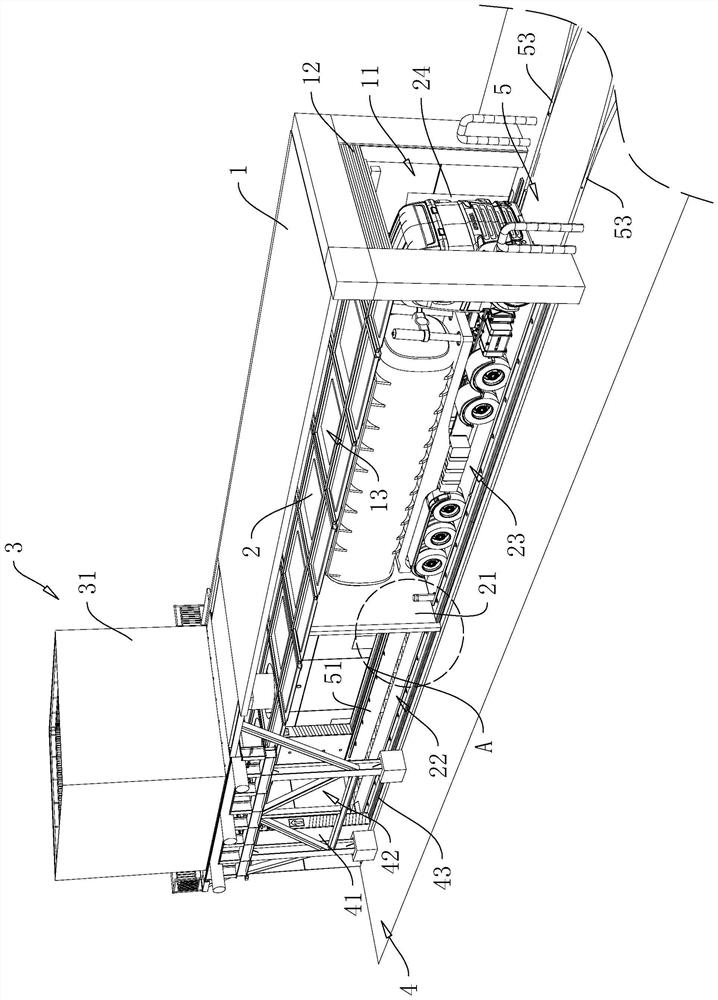

[0043] refer to figure 1 and figure 2, the sludge transfer system includes a charging workshop 1, a charging bin 2 set in the charging workshop 1, a bin main module 3 erected above the charging bin 2, and a cleaning and drying module 4 set inside the charging bin 2 , one side of the loading workshop 1 is provided with a warehouse opening 11 for the transfer vehicle to enter and exit, and a sealing door 12 for controlling the opening and closing of the warehouse opening 11 is provided at the warehouse opening 11, and the sealing door 12 is a rolling shutter door; The shape of the silo 2 is a cuboid, and one end of the silo 2 is connected to the silo port 11, so that the transfer vehicle entering the loading workshop 1 from the silo port 11 can directly enter the silo 2; The end of the bin 2 away from the bin mouth 11, the discharge port of the bin main module 3 is communicated with the inn...

Embodiment 2

[0058] This embodiment provides a sludge transfer method based on the sludge transfer system in Embodiment 1, comprising the following steps:

[0059] S1. Close the compartment door, open the sealing door 12, and the transfer vehicle enters the buffer zone;

[0060] S2. Close the sealing door 12, open the compartment door, and the transfer vehicle enters the loading area and drives directly below the main module 3 of the silo;

[0061] S3. Loading;

[0062] S4. Spray cleaning and dust removal in the loading area, and air-dry the transfer vehicle;

[0063] S5. The compartment door is opened, and the transfer vehicle enters the buffer zone from the loading area;

[0064] S6. The separation bin door is closed, the sealing door 12 is opened, and the transfer vehicle drives out of the loading bin 2 from the bin mouth 11 .

[0065] In step S3, during the loading process, the unloading dust suppression module 6 can reduce the scattering of dust generated during loading on the one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com