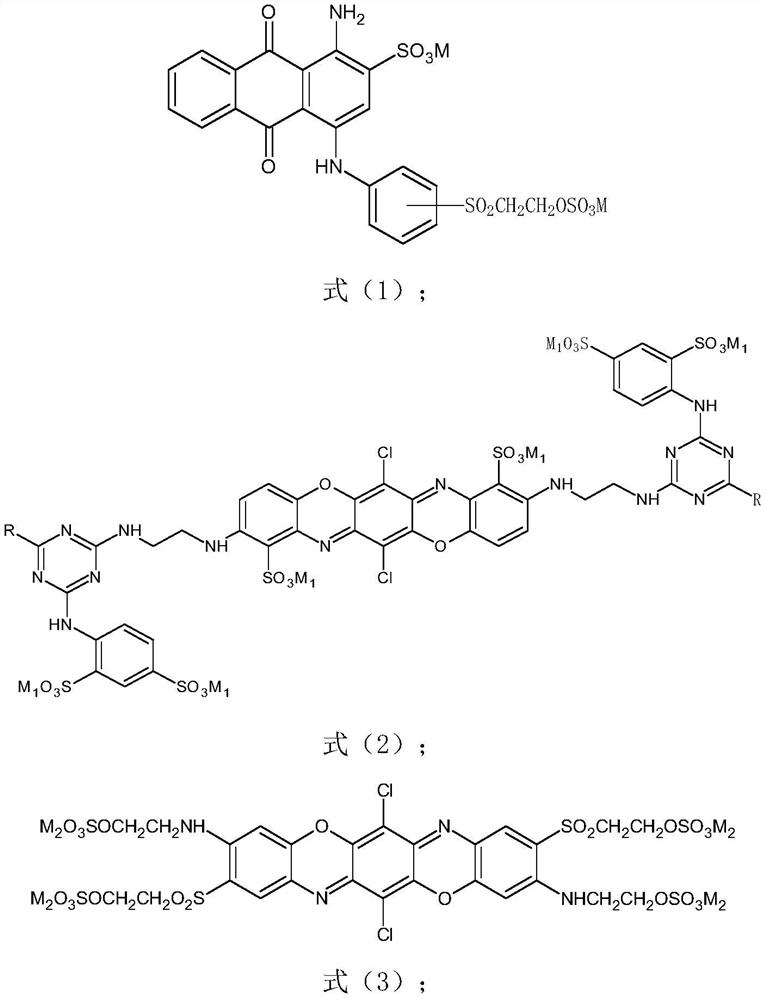

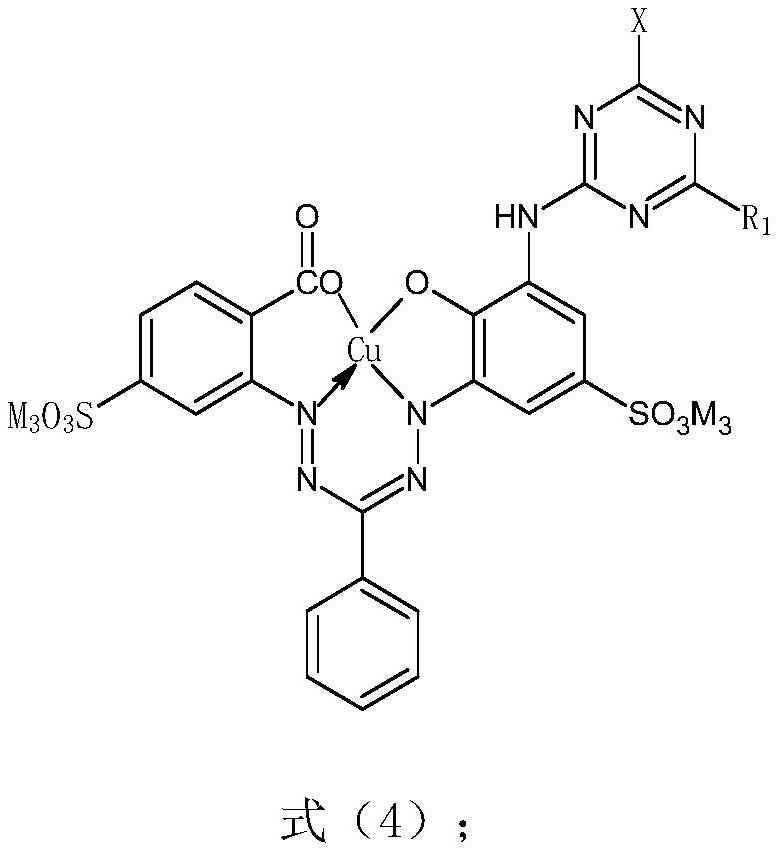

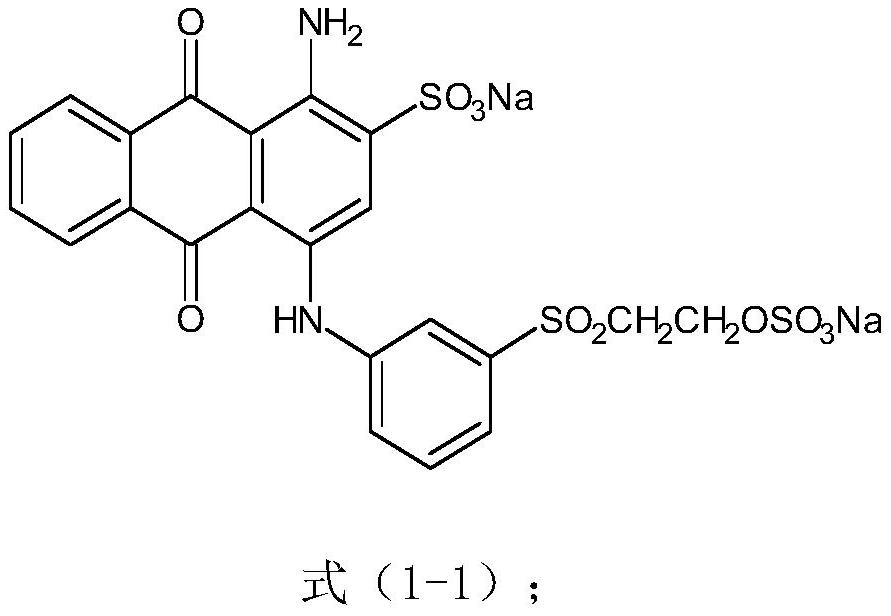

Composite high-light blue reactive dye and application thereof

A reactive dye and blue technology, applied in the field of dyes, can solve problems such as greenish-dark shade, average light fastness, poor light fastness, etc., achieve good color tone reproducibility, excellent fastness index, good direct sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Example: 100g cotton cloth, the composite reactive brilliant blue dye composition obtained in Example 1, 2% by weight of the fabric, in a dye bath containing 60g / L Yuan Ming powder and a liquor ratio of 1:20, at 60°C Adsorb for 30min, add soda ash (amount 15-20g / L) to fix color for 45min, the dyed fabric is washed, soaped and dried to obtain dyed cotton cloth. The dyed cotton cloth has uniform color and satisfactory fastness to sunlight and wet rubbing treatment. The specific performance is shown in Table 2. The higher the grade value, the better the performance.

[0039] Table 2:

[0040]

[0041]

[0042] According to a large number of experimental detections, it is found that the composite reactive blue dye of the present invention has better application performance than the traditional brilliant blue dye, and the specific comparison data is shown in Table 3.

[0043] table 3:

[0044]

[0045]

[0046] As can be seen from Table 2 and Table 3, the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com