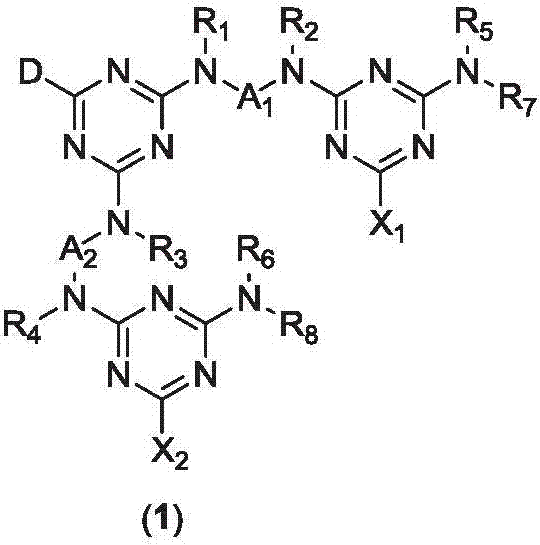

Reactive dye, and composition, preparation method and application thereof

A compound, C1-C4 technology, applied in the direction of reactive dyes, dyeing methods, azo dyes, etc., can solve the problems of low color fixation rate, difficult control, unfavorable environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

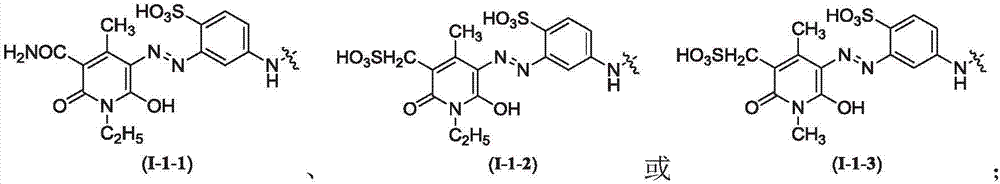

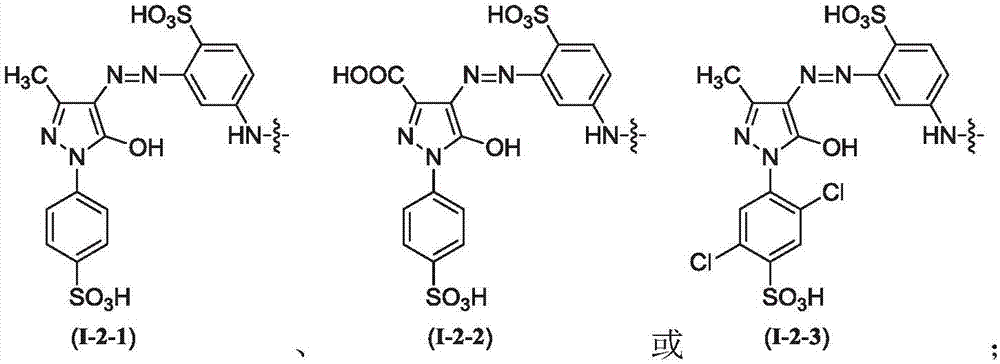

Method used

Image

Examples

Embodiment 1

[0094] 18.8 parts of cyanuric chloride, 70 parts of ice, 50 parts of water and 0.1 part of Pingping plus O25, beat in an ice bath for 45-60 minutes, then add 54.6 parts of compound 8 synthesized by the usual method (dissolved in 220 parts of water in advance), Carry out a condensation, react at 0-5°C, adjust the pH to 6.5-7.0 with 10% sodium carbonate solution, and react for 3.0 hours. The end point is when there is no compound 8. Compound 9 of the following formula was obtained.

[0095]

[0096] Then 21.2 parts of hydroxyethylethylenediamine Add the above-mentioned one-condensate, heat up to 60°C, carry out two-condensation at 60-65°C, use 10% sodium carbonate solution to adjust the pH of the medium to 6.0-7.0, and react for 8.0-10.0h. When there is no compound 9, it is the end point. Compound 10 of the following formula was obtained. Its molecular weight is 828 as tested by HPLC-MS, which is consistent with its structure.

[0097]

Embodiment 2

[0099] 37.6 parts of cyanuric chloride, 140 parts of ice, 100 parts of water and 0.2 parts of Pingping plus O25, beating in an ice bath for 45 to 60 minutes, and then adding 34.6 parts of m-aminobenzenesulfonic acid (dissolved in 400 parts of water in advance) for a Condensate and react at 0-5°C, adjust the pH to 6.5-7.0 with 10% sodium carbonate solution, and react for 3.0 hours. The end point is when there is no m-aminobenzenesulfonic acid. Compound 11 of the following formula was obtained.

[0100]

Embodiment 3

[0102] 37.6 parts of cyanuric chloride, 140 parts of ice, 100 parts of water and 0.2 parts of Pingping plus O25, beat in an ice bath for 45 to 60 minutes, then add 17.3 parts of m-aminobenzenesulfonic acid and 17.3 parts of p-aminobenzenesulfonic acid (pre-dissolved In 400 parts of water), conduct a condensation, react at 0-5°C, adjust the pH to 6.5-7.0 with 10% sodium carbonate solution, and react for 3.0 hours. The end point is when there is no m-aminobenzenesulfonic acid. Compound 12 of the following formula was obtained.

[0103]

[0104]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com