Method for comprehensively recycling zinc and cadmium from cadmium scum

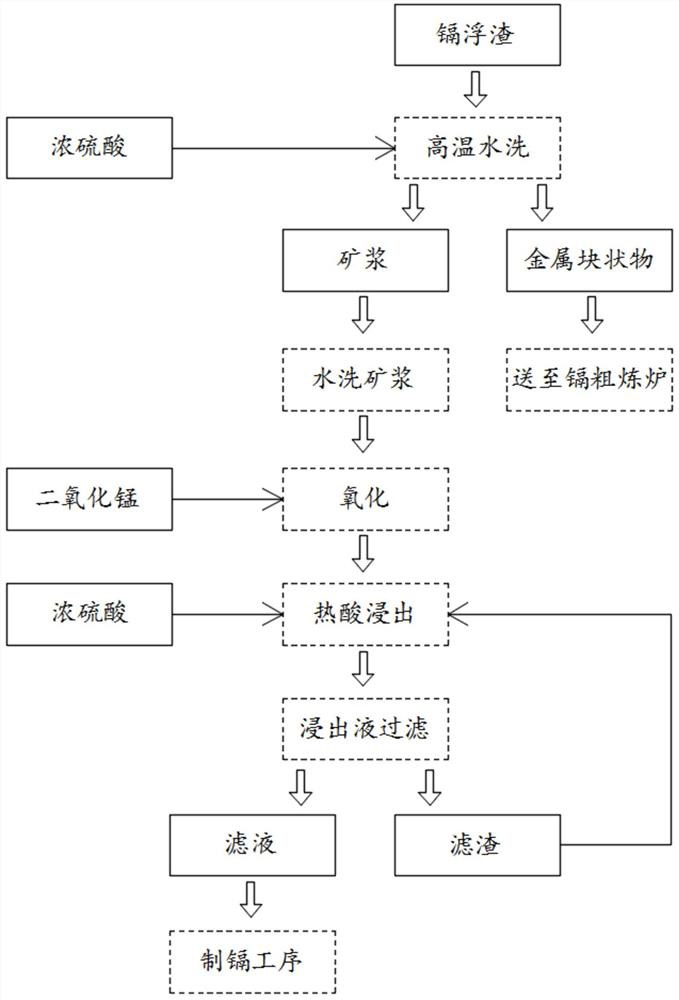

The technology of scum and pulp is applied in the field of comprehensive recovery and utilization of zinc and cadmium from cadmium scum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment comprehensively recycles zinc and cadmium from cadmium scum. The main components in the cadmium scum are: Zn: 23.47%, Cd: 39.52% in weight percentage.

[0020] (1) Take 450 grams of cadmium scum, add water to the cadmium scum at a liquid-solid volume ratio of 5:1 and heat it to a water temperature of 70° C. Slowly add concentrated sulfuric acid at the same time. When the pH value of the solution is less than or equal to 4.5, stop adding concentrated sulfuric acid. Continue the reaction, when the pH value of the solution is higher than 5.0, add concentrated sulfuric acid until the pH value is 4.5, stop adding acid, repeat the above process of adding concentrated sulfuric acid, when the pH value of the pulp is stable between 4.5-5.0 for 30min, the end In the pickling operation of cadmium scum, the pH value of the pulp at the end point is 4.5, and the whole pickling process lasts for 1.0h; the purpose of this process is to make the soluble substances such as...

Embodiment 2

[0026] This embodiment comprehensively recycles zinc and cadmium from cadmium scum. The main components in the cadmium scum are: Zn: 29.92%, Cd: 34.82% in weight percentage.

[0027] (1) Take 320 grams of cadmium scum, add water to the cadmium scum at a liquid-solid volume ratio of 5:1, and heat it to a water temperature of 70° C. Slowly add concentrated sulfuric acid at the same time. When the pH value of the solution is less than or equal to 4.5, stop adding concentrated sulfuric acid. Continue the reaction, when the pH value of the solution is higher than 5.0, add concentrated sulfuric acid until the pH value is 4.5, stop adding acid, repeat the above process of adding concentrated sulfuric acid, when the pH value of the pulp is stable between 4.5-5.0 for 30min, the end In the pickling operation of cadmium scum, the pH value of the pulp at the end point is 4.5, and the whole pickling process lasts for 1.0h; the purpose of this process is to make the soluble substances such a...

Embodiment 3

[0033] This embodiment comprehensively recycles zinc and cadmium from cadmium scum. The main components in the cadmium scum are: Zn: 29.21%, Cd: 36.12% in weight percentage.

[0034] (1) Take 410 grams of cadmium scum, add water to the cadmium scum at a liquid-solid volume ratio of 5:1 and heat it to a water temperature of 70°C, and slowly add concentrated sulfuric acid, when the pH value of the solution is less than or equal to 4.5, stop adding concentrated sulfuric acid, Continue the reaction, when the pH value of the solution is higher than 5.0, add concentrated sulfuric acid until the pH value is 4.5, stop adding acid, repeat the above process of adding concentrated sulfuric acid, when the pH value of the pulp is stable between 4.5-5.0 for 30min, the end In the pickling operation of cadmium scum, the pH value of the pulp at the end point is 4.5, and the whole pickling process lasts for 1.0h; the purpose of this process is to make the soluble substances such as zinc, sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com