Light mineral wool fiber felt needling forming device

A technology of mineral wool fiber and forming device, which is used in acupuncture machines, transportation and packaging, and dust removal. , Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

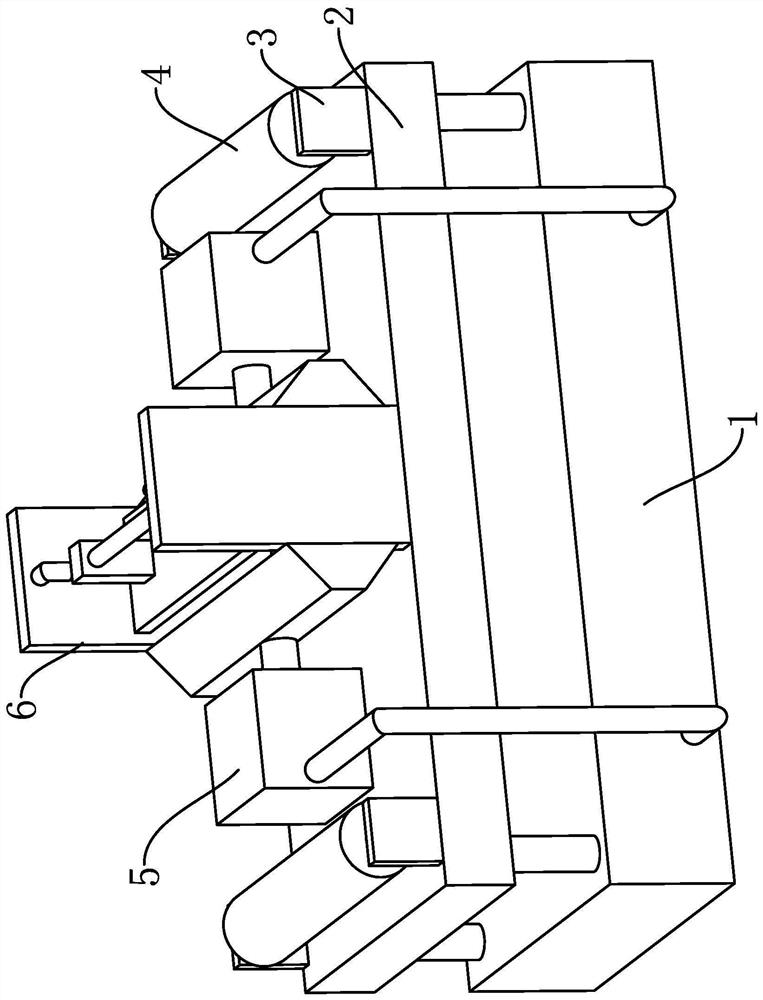

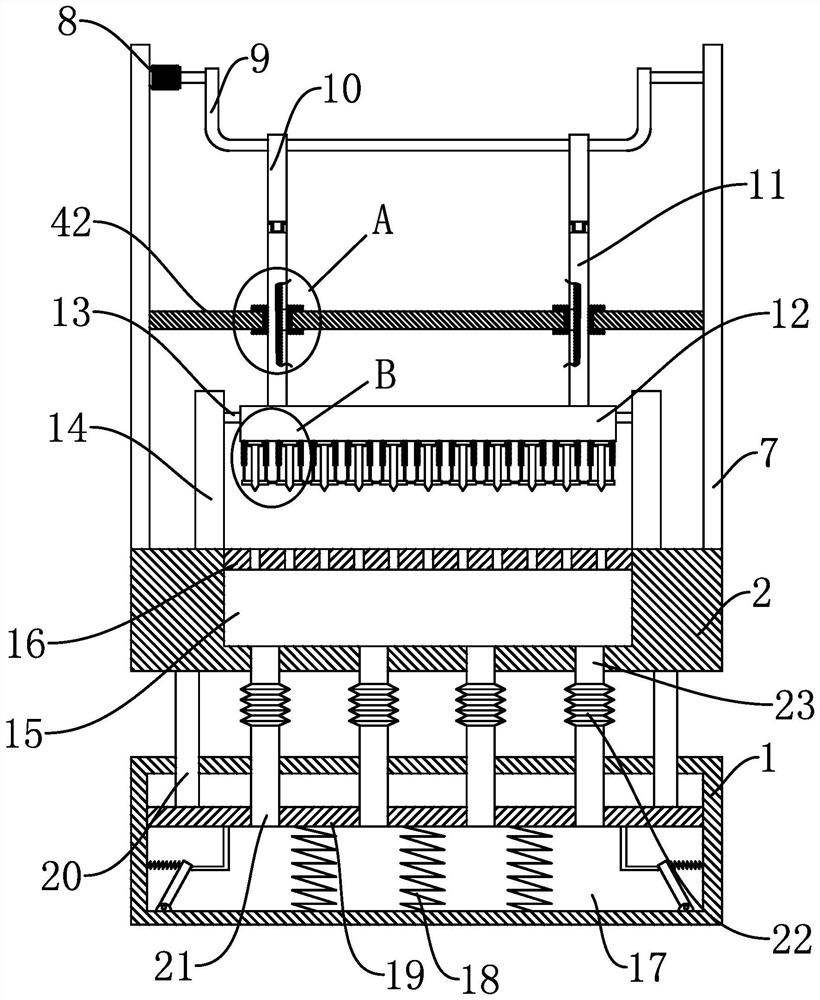

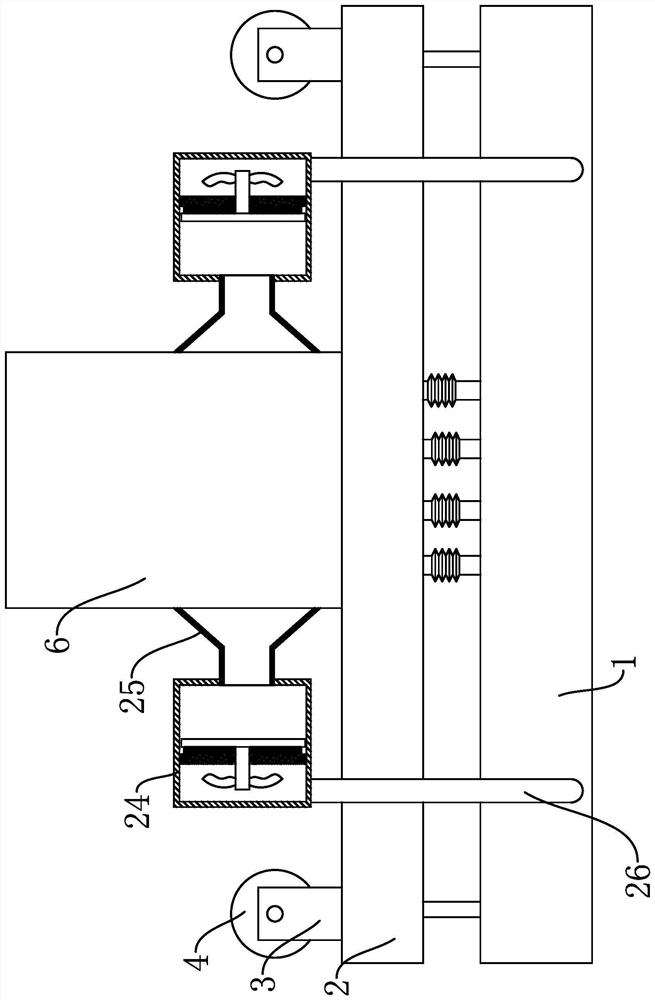

[0045] like Figure 1-Figure 10 As shown in the figure, the light-weight mineral wool fiber felt needle-punching forming device includes a workbench 2 on which a needling mechanism 6 is arranged, and the needling mechanism 6 includes two vertical plates 7, which are fixed on the On the upper side of the table 2, a guide plate 14 is fixed between the two vertical plates 7, a motor 8 is fixed on the upper end of one of the vertical plates 7, and a U-shaped rod 9 is fixed on the output shaft end of the motor 8, and the U-shaped rod 9 rotates on the upper side. A driving rod 10 is connected, the lower end of the driving rod 10 is rotatably connected with a lifting rod 11, a limiting slot is provided on the limiting plate 42, the lifting rod 11 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com