Silk fabric preshrinking device

A pre-shrinking and fabric technology, applied in the direction of fabric surface trimming, textile material carrier treatment, spray/jet textile material treatment, etc., can solve the problems of uniform moisture, poor adjustment, and difficulty in controlling the amount of shrinkage, so as to improve work efficiency. , tightening and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

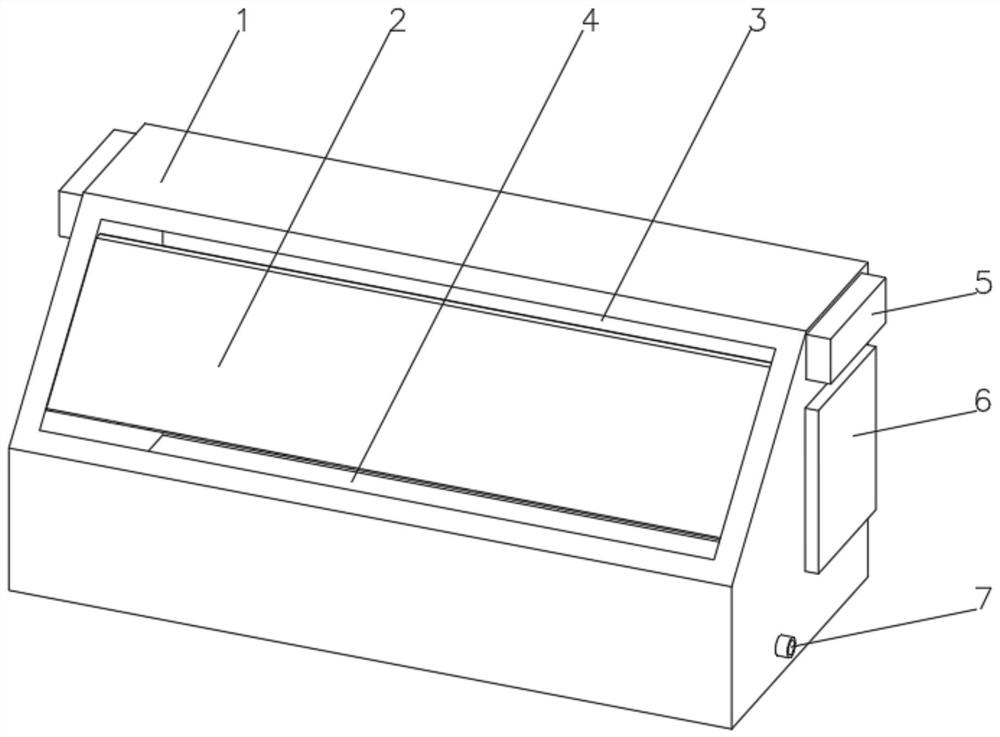

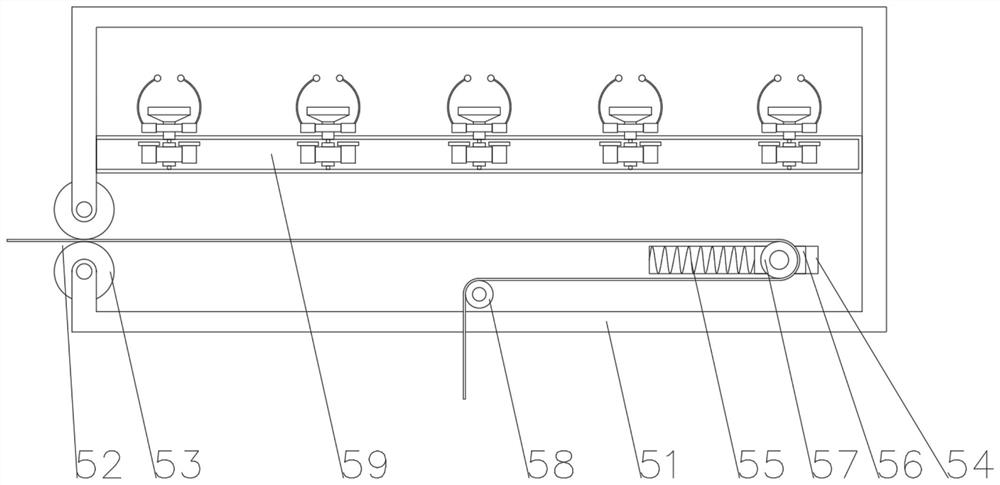

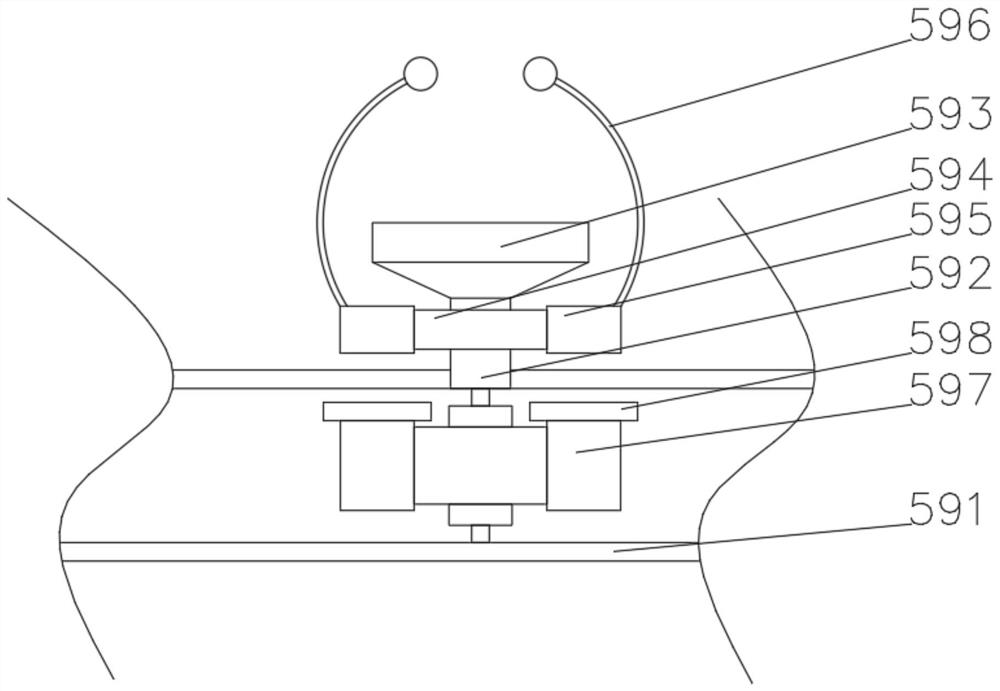

[0033] see Figure 1-5, the present invention provides a technical solution: a silk fabric pre-shrinking device, comprising a processing cabinet 1, a window 2 is opened on one side of the processing cabinet 1, a feeding port 3 is opened at the top of the window 2, and a discharge port is opened at the bottom of the window 2 4. The part of the inner wall of the processing box 1 located on the side of the feed port 3 is fixedly connected with a humidification device 5, the part of the inner wall of the processing box 1 located below the humidification device 5 is fixedly connected with a pre-shrinking device 6, and the bottom of the inner wall of the processing box 1 is located at the pre-shrinking device 6. The part below the device 6 is fixedly connected with a drying device 7, and the material outlet of the drying device 7 is communicated with the material outlet 4. The humidification device 5 includes a humidification box 51, and a material inlet 52 is opened on one side of t...

Embodiment 2

[0036] see Figure 1-6 , on the basis of the first embodiment, the present invention provides a technical solution: the pre-shrinking device 6 includes a pre-shrinking box 61, the top of the inner wall of the pre-shrinking box 61 is rotatably connected with a feeding pressure roller 62, and the inner wall of the pre-shrinking box 61 is located at the feeding pressure roller 62. The lower part is fixedly connected with a heating box 63, one side of the inner wall of the heating box 63 is fixedly connected with a fixed electric heating plate 64, and the side of the inner wall of the heating box 63 away from the fixed electric heating plate 64 is fixedly connected with a compression spring 65, and the compression spring 65 is close to the fixed electric heating plate 64. One end of the electric heating plate 64 is fixedly connected with a movable electric heating plate 66 , a side of the movable electric heating plate 66 close to the compression spring 65 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com