Method and device for evaluating aging degree of transformer oil and sensing system

A transformer oil aging degree technology, applied in the field of transformer oil, can solve the problems that the aging degree of transformer oil cannot be reflected in time, the information is single, and it is difficult to accurately judge the aging degree of transformer oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

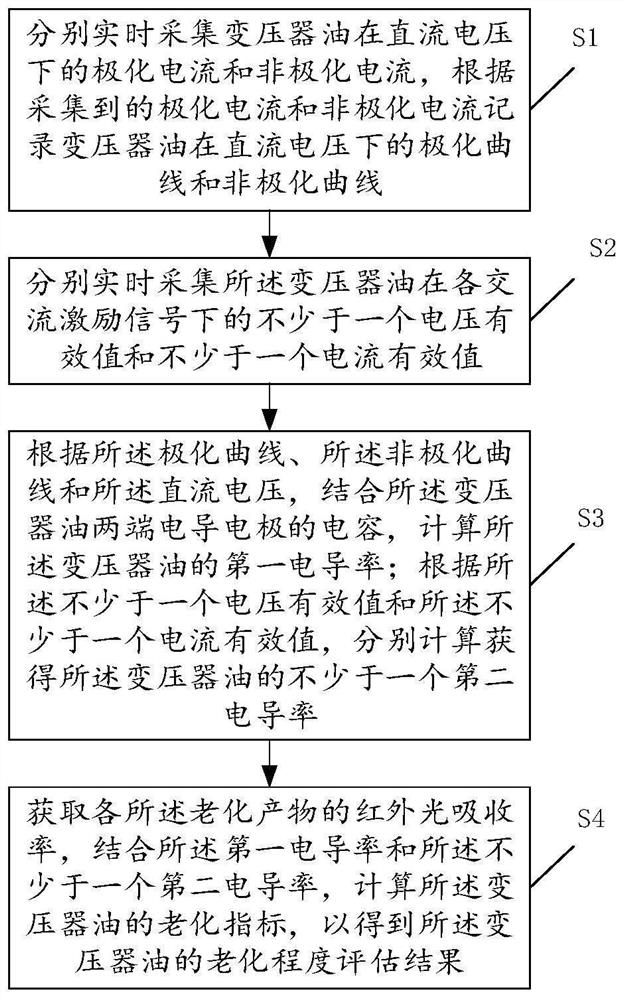

[0045] Please refer to figure 1 , figure 1 A method for evaluating the aging degree of transformer oil provided in an embodiment of the present invention includes steps S1 to S4; wherein,

[0046] In step S1, the polarization current and non-polarization current of the transformer oil under the DC voltage are collected in real time, respectively, and the polarization curve and the non-polarization curve of the transformer oil under the DC voltage are recorded according to the collected polarization current and non-polarization current. ; wherein, the polarization curve is the curve of the polarization current of the transformer oil changing with time; the non-polarization curve is the curve of the non-polarization current of the transformer oil changing with time.

[0047] In this embodiment, a DC voltage U is applied to the conductance electrodes at both ends 0 , real-time acquisition of polarized current and non-polarized current of transformer oil at this time. With the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com