Ion-conductive ceramic and method for producing same

A technology of conductivity and ceramics, which is applied in the field of synthesizing the above-mentioned new ceramics, can solve the problems of uneven particle size, crystallinity difference, instability, etc., and achieve the effect of high ionic conductivity and excellent electrochemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

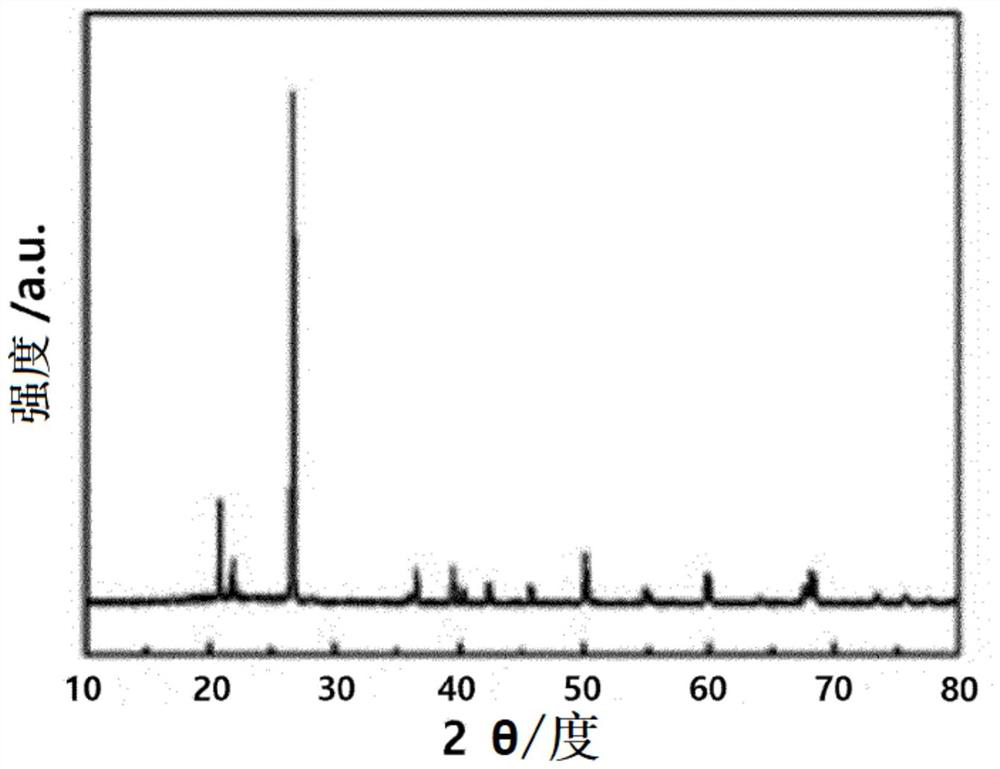

[0054] The synthetic chemical composition is Li 1+x Al x Si 2-x P 3 O 12 (x=0.3) NASICON structure oxide-based conductive ceramics

[0055] LiCl, Al (NO 3 ) 3 ·9H 2 O, NH 4 H 2 PO 4 , C 8 H 20 O 4 After the Si is calculated as stoichiometric, each is mixed in a molar ratio of 1.3:0.3:3:1.7. After that, zirconia balls with diameters of 5 mm and 10 mm were prepared at a ratio of 2:1, and placed in a prepared 500-ml container, so that the volume ratio of the mixed sample and zirconia balls was 1:1. The rotation speed of the ball mill was 200 to 300 RPM, and the ball milling was performed for 24 hours. After ball milling for 24 hours, the zirconia balls were removed. After that, a heat treatment was performed at 400° C. for 3 hours. The chemical composition of Li is synthesized by grinding and pulverizing the heat-treated powder in a mortar and then performing a secondary heat treatment at 900°C for 4 hours. 1+x Al x Si 2-x P 3 O 12 (x=0.3) oxide-based conduct...

Embodiment 2

[0057] The synthetic chemical composition is Li 1+x Zr 2 Si x P 3-x O 12(x=2) NASICON structure oxide-based conductive ceramics

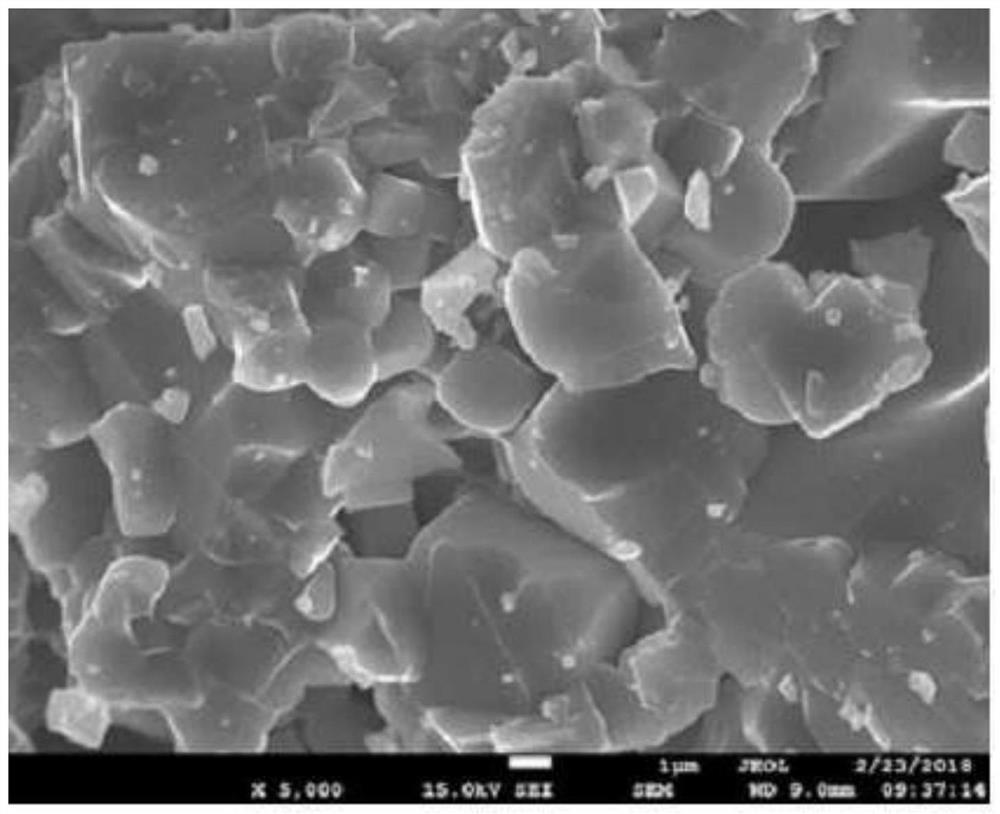

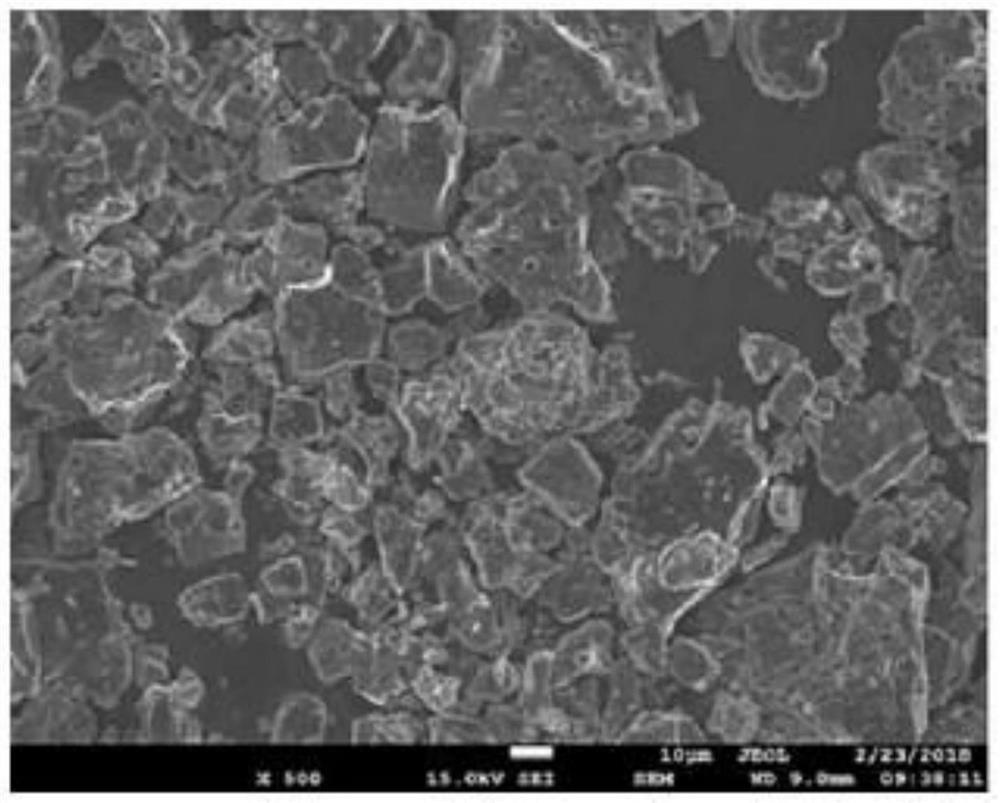

[0058] Will Li 3 PO 4 , SiO 2 , ZrO 2 Each was mixed in a 1:2:2 molar ratio after stoichiometric calculations. After that, zirconia balls with diameters of 5 mm and 10 mm were prepared at a ratio of 2:1, and placed in a prepared 500-ml container, so that the volume ratio of the mixed sample and zirconia balls was 1:1. The rotation speed of the ball mill was 200 to 300 RPM, and the ball milling was performed for 10 hours. After ball milling for 10 hours, the zirconia balls were removed. After that, a heat treatment was performed at 400° C. for 5 hours. The chemical composition is Li by grinding and pulverizing the heat-treated powder in a mortar, followed by a secondary heat treatment at 1100°C for 12 hours. 1+x Zr 2 Si x P 3-x O 12 The oxide-based conductive ceramic of the NASICON structure of (x=2). figure 2 SEM images of the cond...

Embodiment 3

[0060] The synthetic chemical composition is Li 1+x Al x Si 2-x P 3 O 12 (x=0.3) NASICON structure oxide-based conductive ceramics

[0061] LiCl, Al (NO 3 ) 3 ·9H 2 O, NH 4 H 2 PO 4 , C 8 H 20 O 4 After Si was calculated according to the stoichiometry, each was placed in 500 ml of distilled water in a molar ratio of 1.3:0.3:3:1.7. After that, zirconia balls with diameters of 5 mm and 10 mm were prepared at a ratio of 2:1, and placed in a prepared 500-ml container, so that the volume ratio of the mixed sample and zirconia balls was 1:1. The rotation speed of the ball mill was 200 to 300 RPM, and the ball milling was performed for 24 hours. After ball mill mixing for 24 hours, the zirconia balls were removed and dried at 80°C for 12 hours. After that, a heat treatment was performed at 400° C. for 3 hours. The chemical composition of Li is synthesized by grinding and pulverizing the heat-treated powder in a mortar and then performing a secondary heat treatment at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com