Modularized seeding machine convenient to assemble in field

A modularized seeder technology, applied in sowing seeders, planting methods, agricultural gas emission reduction, etc., can solve the problems of inconvenient storage of seeders, and achieve the effect of increasing versatility, convenient storage, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

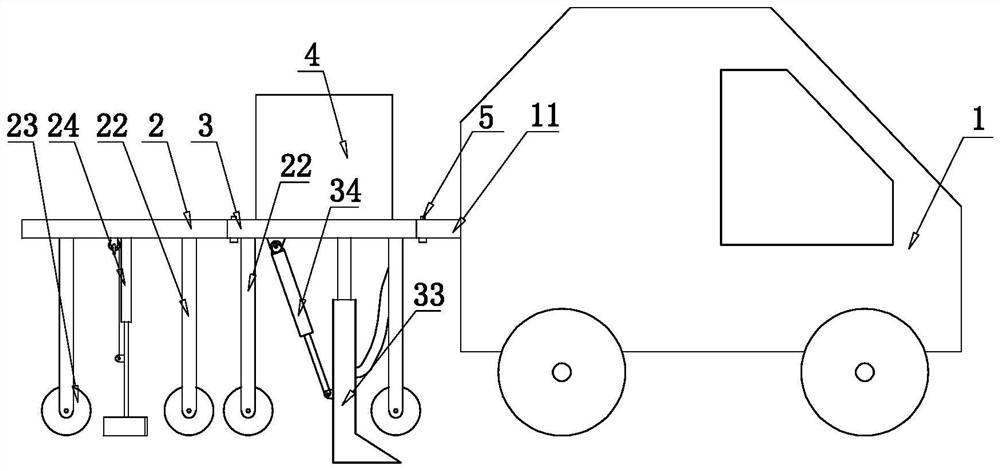

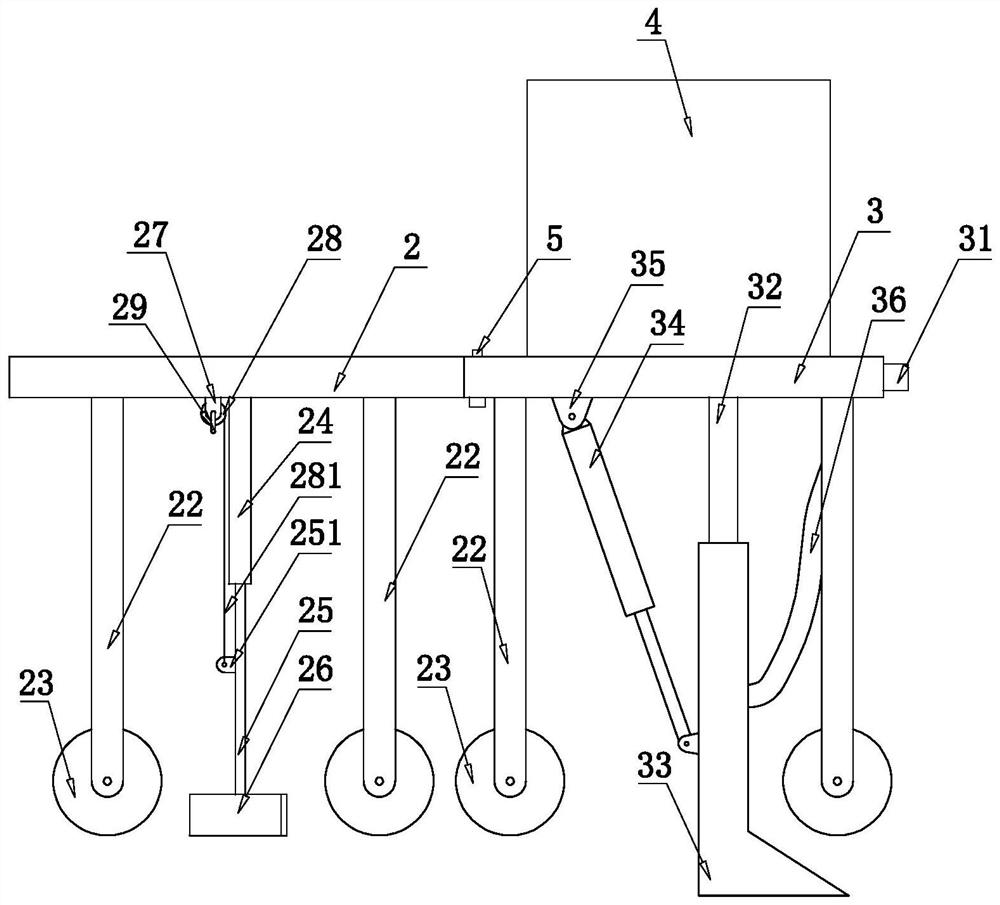

[0024] like Figure 1 to Figure 8 As shown, the present invention mainly includes a vehicle body 1, a ditching mechanism, a seeding mechanism and a soil covering mechanism. The present invention will be described in detail below with reference to the accompanying drawings.

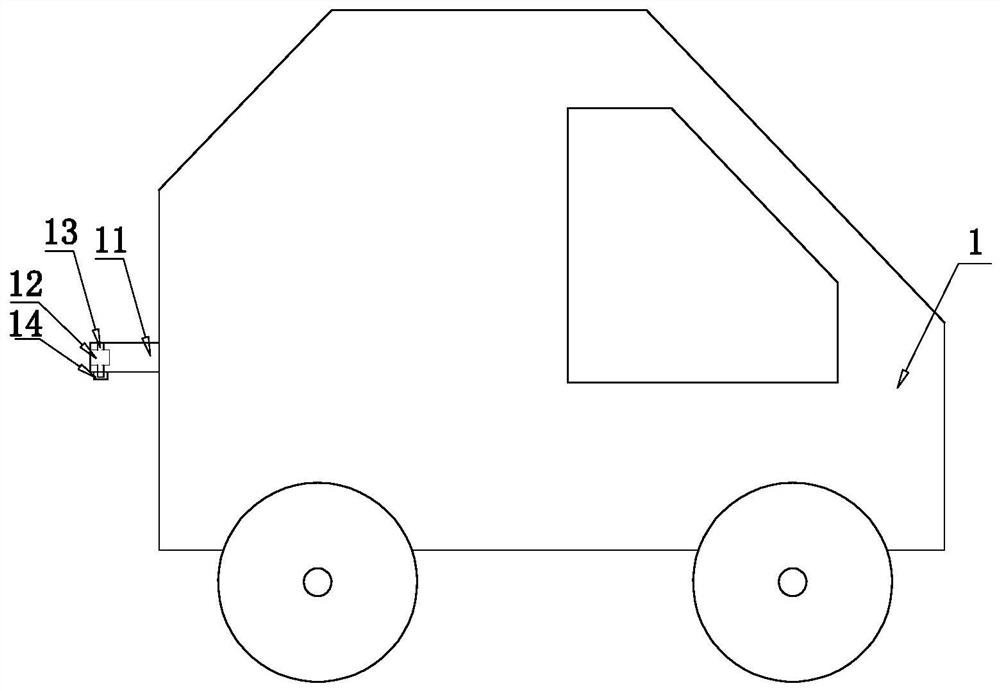

[0025] like figure 1 , figure 2 As shown, the vehicle body 1 is a traction component of the present invention, a mounting rod 11 is fixed on the vehicle body 1, a groove 12 is provided on the rear side wall of the mounting rod 11, and a vertical arrangement is also provided on the mounting rod 11 The vertical hole 13 passes through the groove 12 in the vertical direction. A nut 14 is fixed on the bottom of the mounting rod 11 , and a bolt can be inserted into the vertical hole 13 during use, and the threaded rod of the bolt is threadedly connected with the nut.

[0026] The rear side of the vehicle body 1 is provided with a ditching mechanism and an earth-covering mechanism arranged in sequence from fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com