Automatic foam injection system and method for preventing cutting sparks of coal mining machine

A jetting system and shearer technology, applied in the fields of slitting machinery, earth drilling, fire rescue, etc., can solve the problems of high operating cost and ineffective prevention and control of cutting sparks, and achieve low operating cost and small space occupation , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

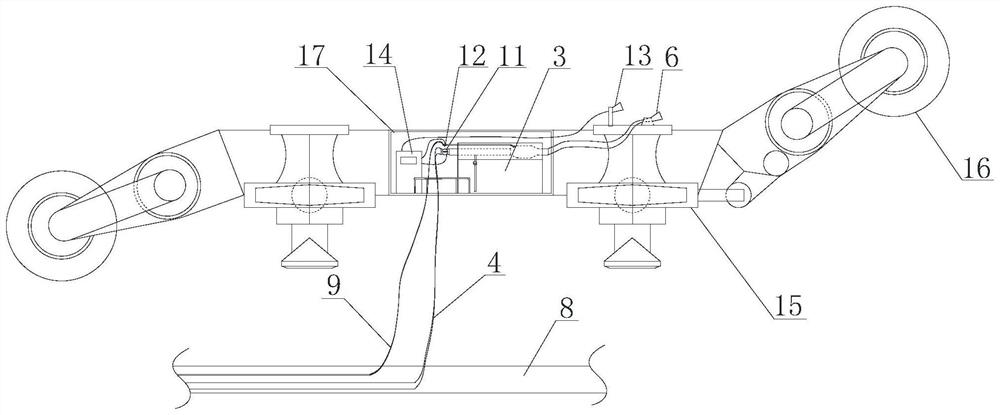

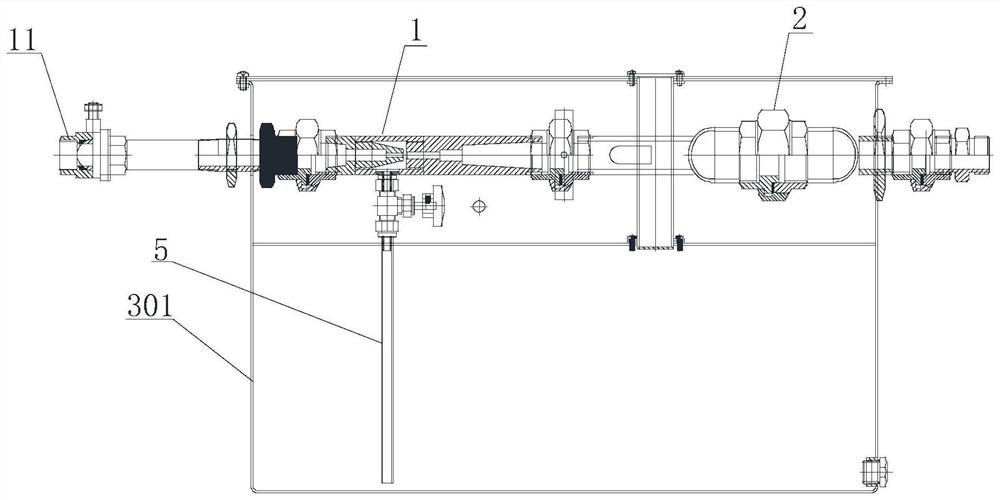

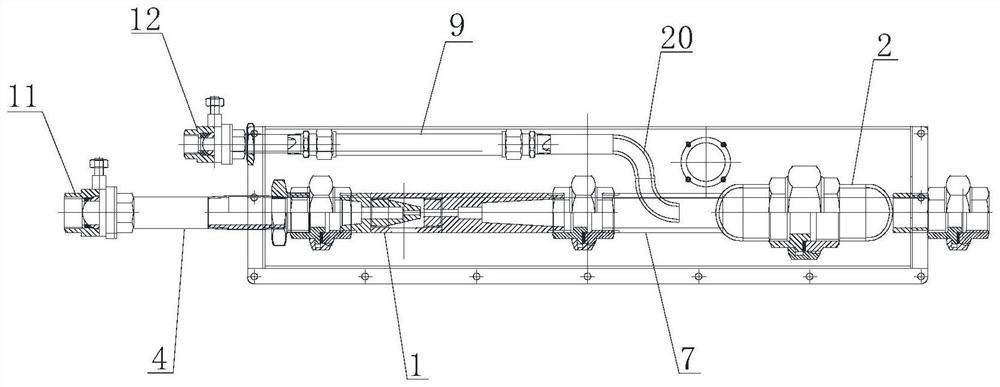

[0034] With reference to the accompanying drawings, an automatic foam injection system for preventing and controlling cutting sparks of a shearer includes a foam generating device for preparing foam and a control device for controlling the automatic injection of the prepared foam. The foam generating device includes a foaming liquid proportional mixer 1, a gas-liquid mixer 2 and a foaming liquid storage tank 3. One end of the foaming liquid proportional mixer 1 is connected to a high-pressure water pipe 4, and the foaming liquid proportional mixer 1 passes through suction. The liquid pipe 5 is connected to the foaming liquid storage tank 3. Since the high-pressure water forms a Venturi liquid absorption effect when passing through the foaming liquid proportioning mixer 1, the liquid is automatically absorbed to achieve a mixed liquid with a specific foaming liquid ratio. The other end of the foaming liquid proportional mixer 1 is connected to the gas-liquid mixer 2 through a fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com