Machining device of detachable bookshelf and using method

A technology for processing devices and bookshelves, which is applied to manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as damage to metal plates, the difficulty of achieving a vertical state of the bending angle, and the inability to observe the state of the bending angle at the bending point at any time. The effect of preventing instability and ensuring the convenience of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following:

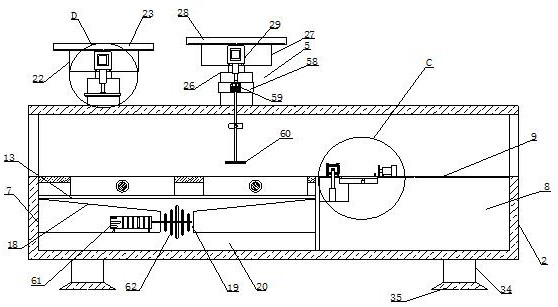

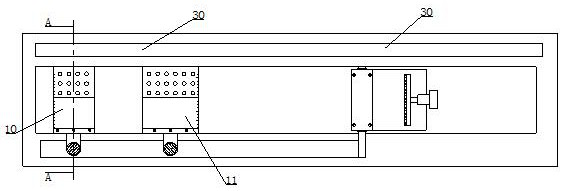

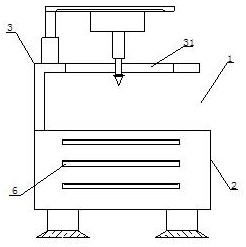

[0038] like Figures 1~10 As shown, a processing device for a detachable bookshelf includes a processing device body 1. The processing device body 1 includes a processing box body 2 and an L-shaped support frame 3 arranged above the processing box body 2. The L-shaped support frame 3 is provided with There are an edge trimming device 4 and a drilling surface grinding mechanism 5. The integrated setting of the edge trimming device 4 and the drilling surface grinding mechanism 5 ensures the continuity of processing and improves the processing efficiency. There are ventilation strips 6, the processing box 2 is provided with a first cavity 7 and a second cavity 8, and the top of the second cavity 8 is provided with a processing panel 9, and one end of the processing panel 9 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com