Carbon continuous production line

A production line, carbon technology, applied in the direction of biofuel, transportation and packaging, conveyor objects, etc., can solve the problem of continuous and automatic processing, time-consuming and labor-intensive, and the amount of material added cannot be automatically controlled according to needs. Quantity and other issues to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

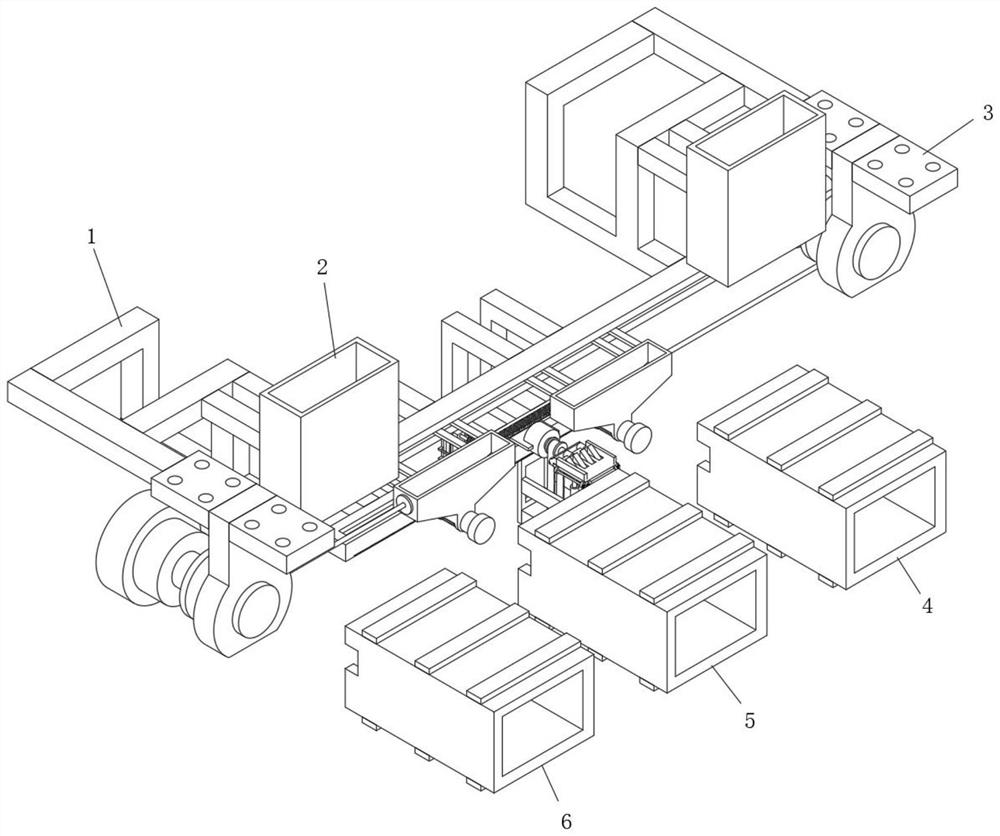

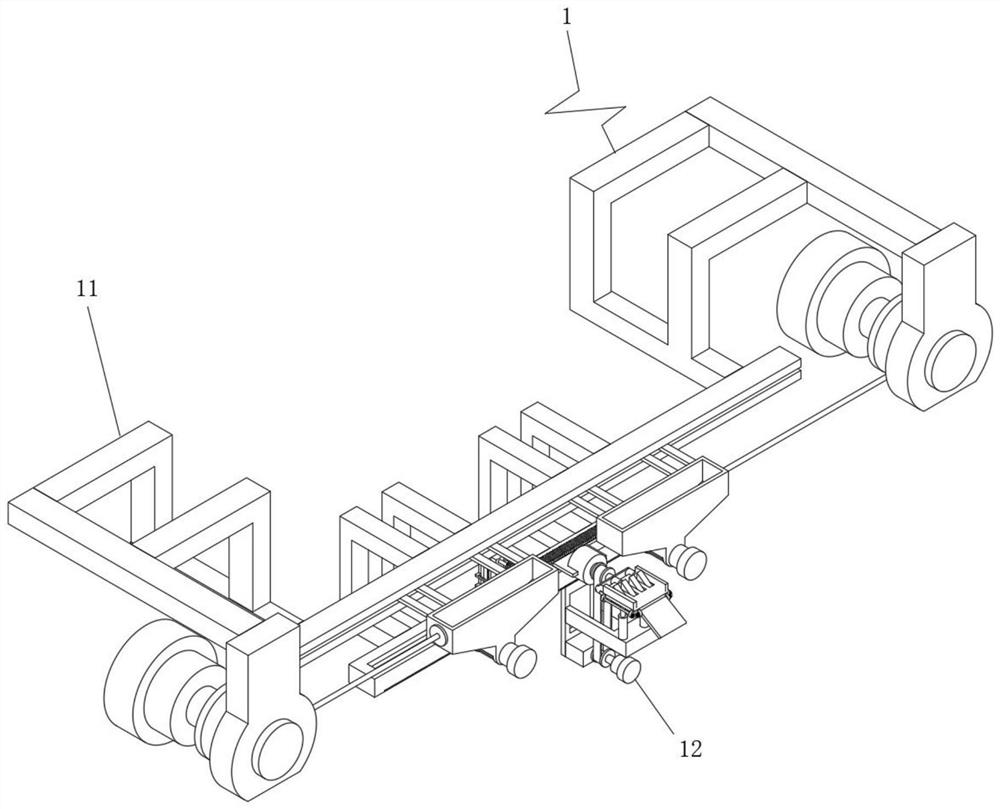

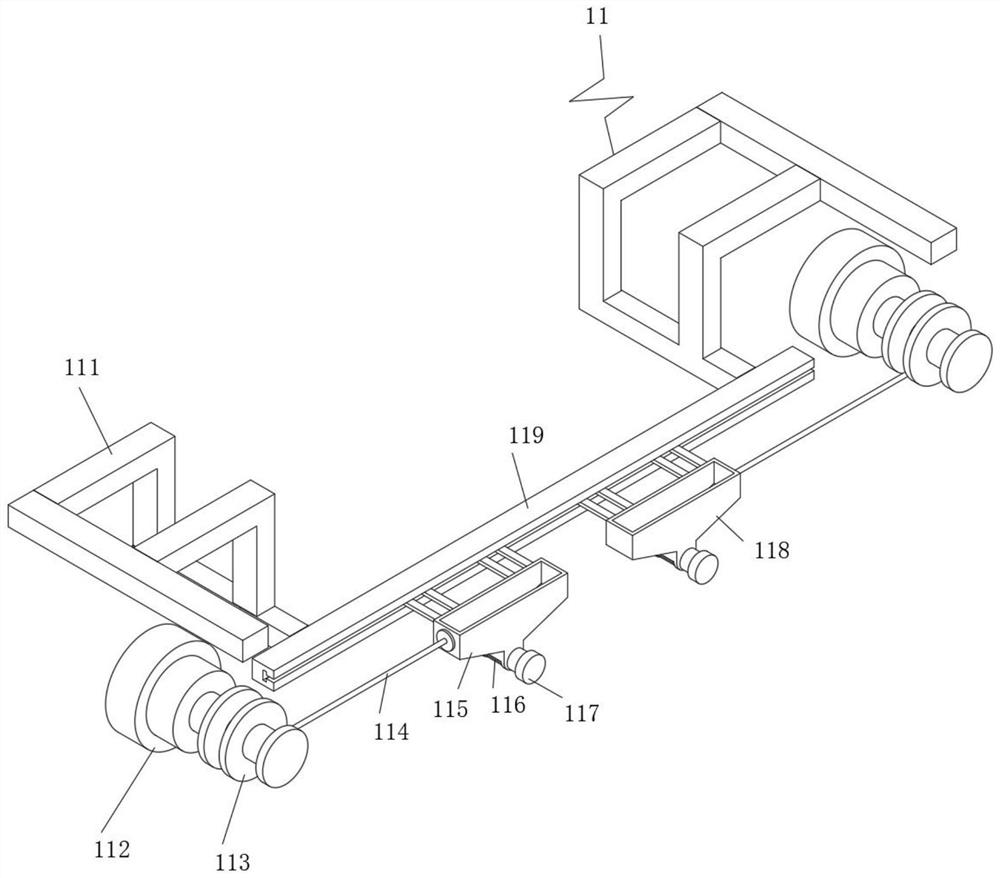

[0027] like Figure 1-Figure 6 As shown, a carbon continuous production line of the present invention includes a feeding material control body 1, a storage bin 2, a fixed plate 3, a first heating furnace 4, a second heating furnace 5 and a third heating furnace 6. The silo 2 is symmetrically and fixedly connected to the inside of both ends of the feeding control body 1, the fixing plate 3 is fixedly connected to the upper parts of both ends of the feeding control body 1, the first heating furnace 4, the second heating furnace 5 and the third heating furnace 6 It is evenly and fixedly distributed under one side of the feeding control body 1. The structures of the first heating furnace 4, the second heating furnace 5 and the third heating furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com