Hot-melt pressure-sensitive adhesive for assembling new energy battery and preparation method of hot-melt pressure-sensitive adhesive

A technology for hot-melt pressure-sensitive adhesives and battery assembly, applied in adhesives, final product manufacturing, natural rubber adhesives, etc., can solve problems such as reduced bonding performance, and achieve good impact resistance, good moisture resistance and temperature resistance , good and cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

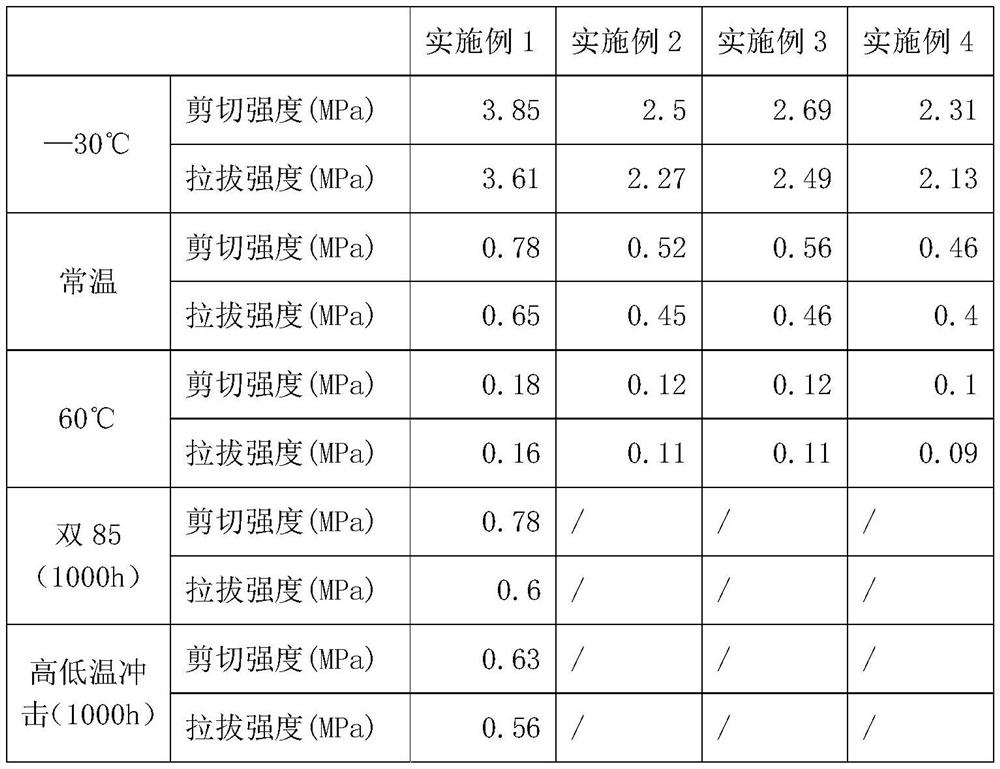

Examples

Embodiment 1

[0034] A hot-melt pressure-sensitive adhesive for assembling a new energy battery, the raw materials of the hot-melt pressure-sensitive adhesive include, in parts by weight, 7 parts of liquid resin, 36 parts of rubber, and 45 parts of tackifying resin;

[0035] The weight ratio of the rubber to the tackifying resin is 0.8:1;

[0036] The rubber is synthetic rubber; the synthetic rubber is a combination of styrene-isoprene-styrene copolymer (SIS) and styrene-ethylene-propylene-styrene copolymer (SEPS); the styrene- The weight ratio of isoprene-styrene copolymer (SIS) to styrene-ethylene-propylene-styrene copolymer (SEPS) is 1:0.65; the styrene-isoprene-styrene copolymer ( SIS) is sold under the designation 4211 (melt index at 200°C, 5.0kg is 1.3g / min); the styrene-ethylene-propylene-styrene copolymer (SEPS) is sold under the trade name SEPTON TM 2004 (melt index 5g / min at 200°C, 5.0kg);

[0037] The tackifying resin is a composition of hydrogenated C5 petroleum resin and hy...

Embodiment 2

[0042] A hot-melt pressure-sensitive adhesive for assembling a new energy battery, the raw materials of the hot-melt pressure-sensitive adhesive include, in parts by weight, 7 parts of liquid resin, 90 parts of rubber, and 45 parts of tackifying resin;

[0043] The weight ratio of the rubber to the tackifying resin is 2:1;

[0044] The rubber is synthetic rubber; the synthetic rubber is a combination of styrene-isoprene-styrene copolymer (SIS) and styrene-ethylene-propylene-styrene copolymer (SEPS); the styrene- The weight ratio of isoprene-styrene copolymer (SIS) to styrene-ethylene-propylene-styrene copolymer (SEPS) is 1:0.65; the styrene-isoprene-styrene copolymer ( SIS) is sold under the designation 4211 (melt index at 200°C, 5.0kg is 1.3g / min); the styrene-ethylene-propylene-styrene copolymer (SEPS) is sold under the trade name SEPTON TM 2004 (melt index 5g / min at 200°C, 5.0kg);

[0045] The tackifying resin is a composition of hydrogenated C5 petroleum resin and hydr...

Embodiment 3

[0050] A hot-melt pressure-sensitive adhesive for assembling a new energy battery, the raw materials of the hot-melt pressure-sensitive adhesive include, in parts by weight, 7 parts of liquid resin, 36 parts of rubber, and 45 parts of tackifying resin;

[0051] The weight ratio of the rubber to the tackifying resin is 0.8:1;

[0052] The rubber is synthetic rubber; the synthetic rubber is a combination of styrene-isoprene-styrene copolymer (SIS) and styrene-ethylene-propylene-styrene copolymer (SEPS); the styrene- The weight ratio of isoprene-styrene copolymer (SIS) to styrene-ethylene-propylene-styrene copolymer (SEPS) is 1:0.65; the styrene-isoprene-styrene copolymer ( SIS) is sold under the designation 4211 (melt index at 200°C, 5.0kg is 1.3g / min); the styrene-ethylene-propylene-styrene copolymer (SEPS) is sold under the trade name SEPTON TM 2004 (melt index 5g / min at 200°C, 5.0kg);

[0053] Described tackifying resin is hydrogenated C5 petroleum resin; Described hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com