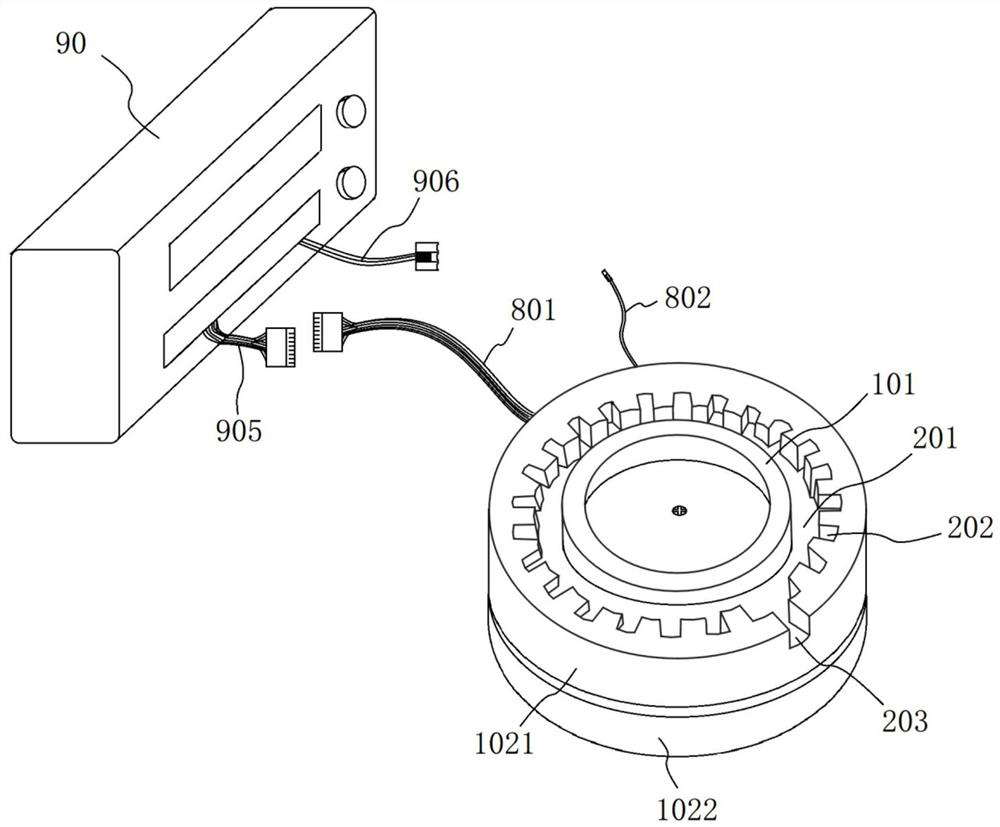

Motor power line conduction testing device

A technology of continuity test and motor power supply, which is applied in the field of motor power line continuity test device, can solve the problems of increasing labor costs, increasing testing procedures, and prolonging working time, so as to achieve convenient and efficient operation, improve test efficiency, and reduce operation time. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

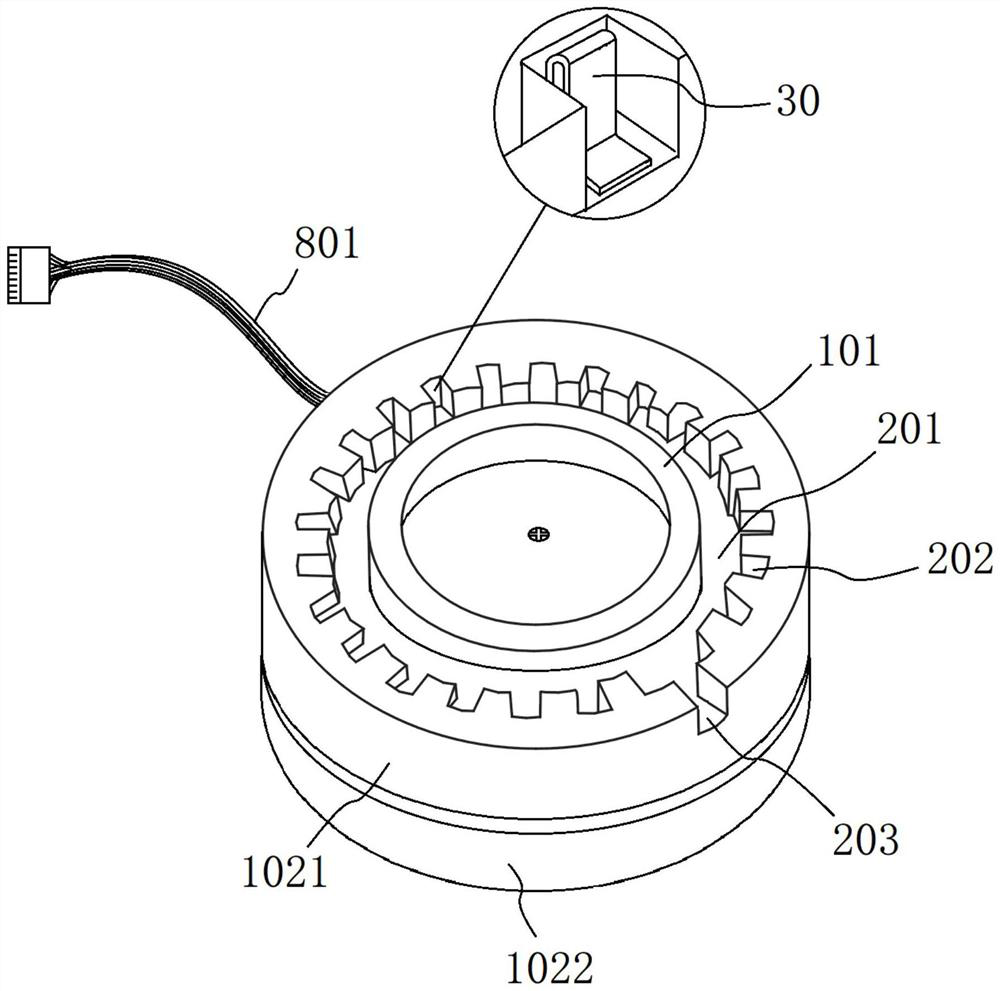

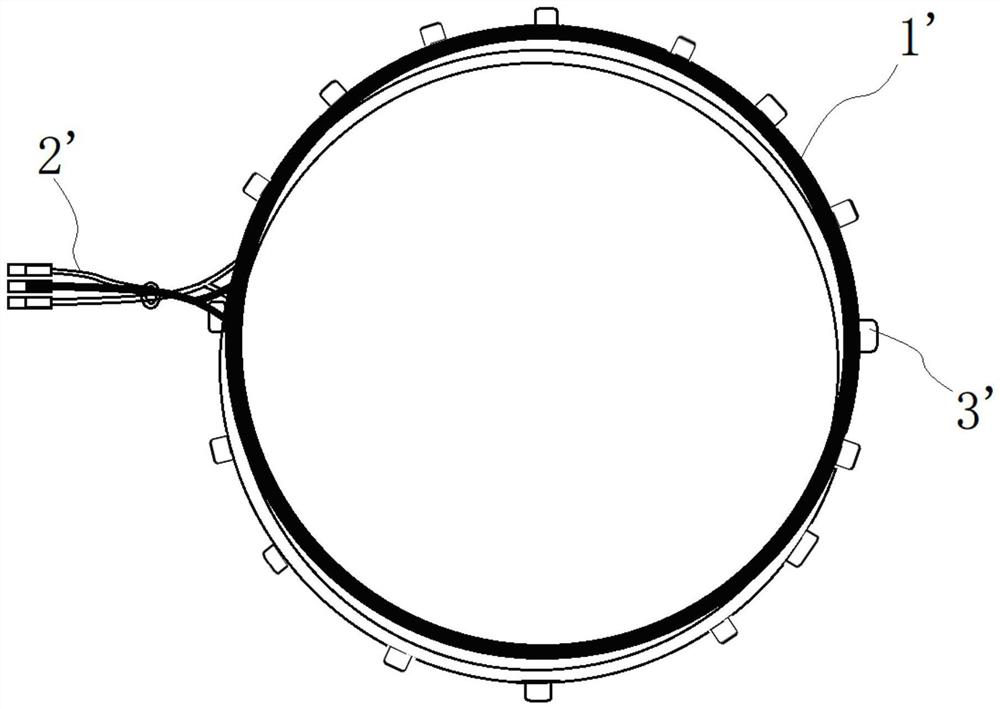

Embodiment Construction

[0035] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to specific drawings. It should be noted that the terms "first", "second", "third", "fourth", etc. (if any) in the description and claims of the present invention are used to distinguish similar objects, and do not necessarily Used to describe a specific order or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances so that the embodiments described herein can be practiced in sequences other than those illustrated or described herein. Furthermore, the terms "comprising" or "having" and any variations thereof are intended to cover a non-exclusive inclusion, for example, a product or device comprising a series of components or units is not necessarily limited to those components or units expressly listed , but may include...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap