Microscopic modeling and multi-scale analysis method suitable for needled composite material

A multi-scale analysis, composite material technology, applied in 3D modeling, instrumentation, geometric CAD, etc., can solve the problems of the needling area not having periodic boundary conditions, unable to meet the needs of complex structural performance evaluation, etc., to avoid analysis Error, the effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

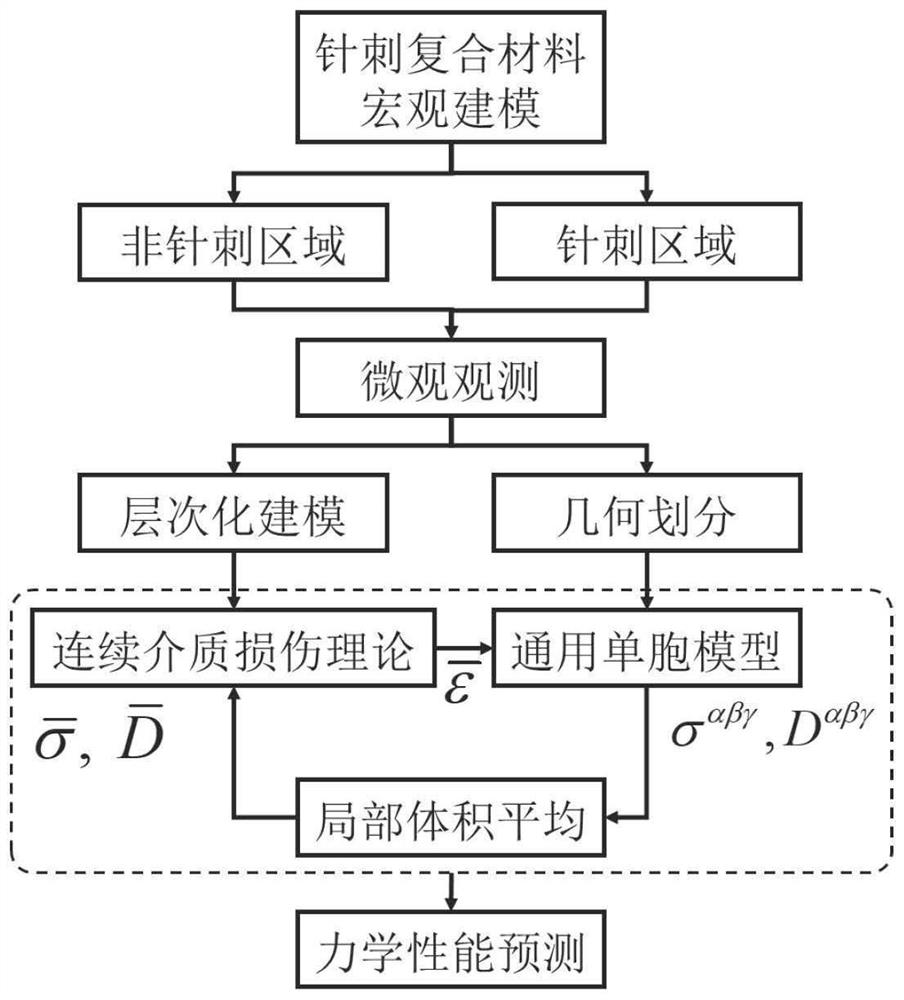

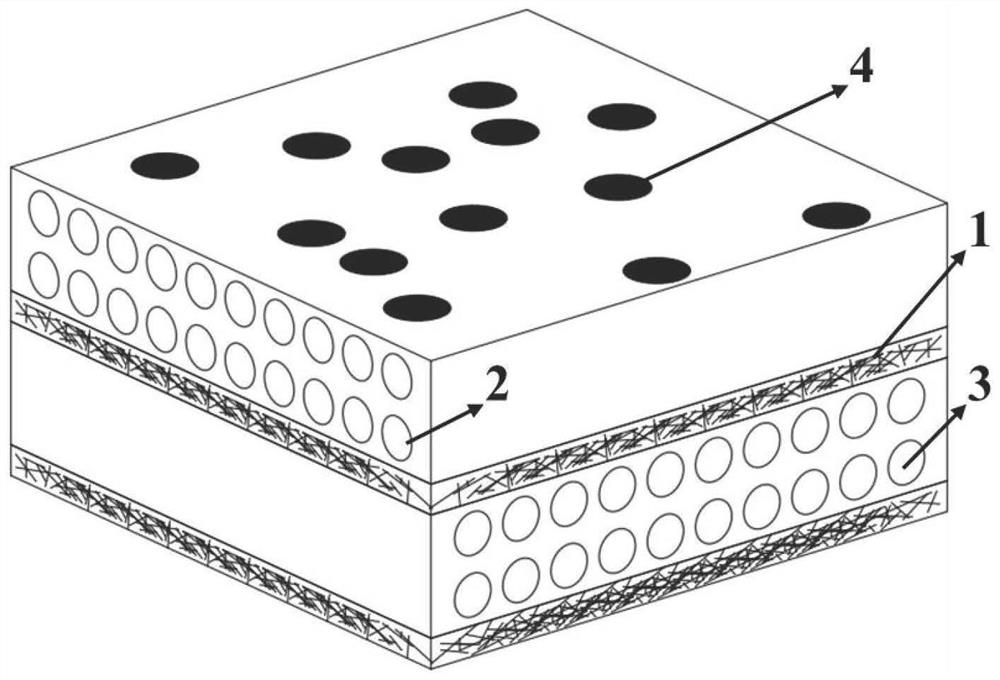

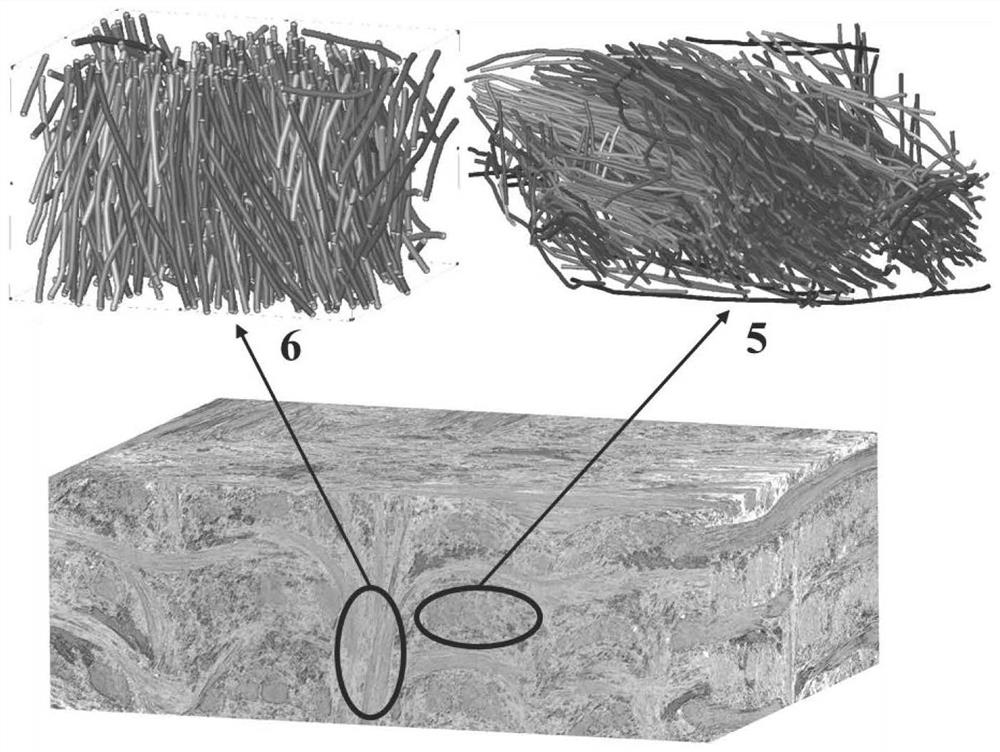

[0041] like figure 1 As shown, the present invention is suitable for the mesoscopic modeling and multi-scale analysis method of acupuncture composite materials. The embodiment of the present invention adopts the C / C-SiC three-dimensional acupuncture composite material. The schematic diagram of the acupuncture process and the specific material phase composition are as follows: figure 2 As shown, the material is formed by alternately laying a first chopped fiber layer 1, a 0° non-woven fabric 2, a second chopped fiber layer 1, and a 90° non-woven fabric 3. Transfer of the planar fiber portion to the thickness direction by vertical penetration of the needle. During this process, a needling area 4 is formed. The specific embodiments of the present invention are as follows:

[0042] The first step is to carry out CT tomography test for the assessment section of the tensile standard specimen of acupuncture composite materials, and use 3D reconstruction software to obtain the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com