Structure optimization method and system for composite dry-type wall bushing

A technology of through-wall casing and optimization method, applied in the field of structural optimization, can solve the problem that the influence cannot be comprehensively considered, and achieve the effect of improving the calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

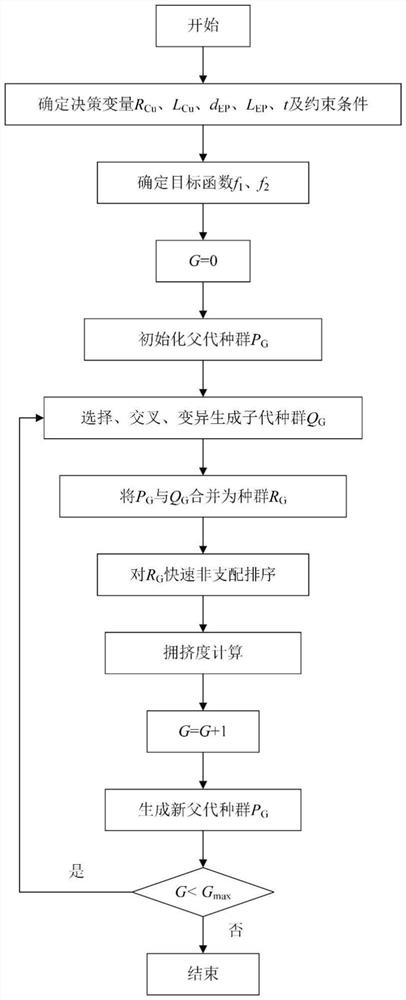

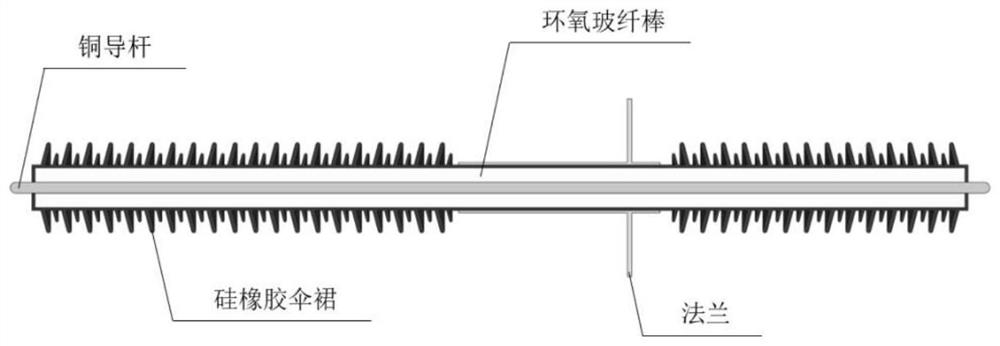

[0071] like figure 1 and 2 As shown, Embodiment 1 of the present invention provides a method for optimizing the structure of a composite dry wall bushing. like image 3 As shown, the composite dry wall bushing includes copper guide rod, inner insulation (epoxy glass fiber rod), outer insulation (high temperature vulcanized silicone rubber shed, namely image 3 The silicone rubber shed in the middle, a large shed and a small shed adjacent to form a shed group) and flanges (exemplary aluminum flanges), with uniform internal electric field distribution, dirt resistance, water repellency and aging resistance.

[0072] The method includes the following steps:

[0073] Step 101: Determine the constraint conditions of each parameter of the structure of the composite drywall bushing; the parameters include: the radius R of the copper guide rod Cu , copper guide rod length L Cu , epoxy glass fiber rod thickness d EP , epoxy glass fiber rod length L EP , the number of umbrella s...

Embodiment 2

[0099] Embodiment 2 of the present invention provides a structure optimization system for a composite drywall bushing, the system comprising:

[0100] The constraint condition determination module is used to determine the constraint conditions of each parameter of the structure of the composite drywall bushing; the parameters include: the radius R of the copper guide rod Cu , copper guide rod length L Cu , epoxy glass fiber rod thickness d EP , epoxy glass fiber rod length L EP , the number of umbrella skirt groups n.

[0101] The constraints are:

[0102]

[0103] where R Cu,min and R Cu,max Respectively, the radius R of the copper guide rod Cu The minimum and maximum values, L Cu,min and L Cu,max respectively the length L of the copper guide rod Cu The minimum and maximum values of d EP,min and d EP,max Respectively, the thickness d of epoxy glass fiber rod EP The minimum and maximum values, L EP,min and L EP,max Respectively, the length L of epoxy glass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com