Rolling bearing fault diagnosis method and device based on time-frequency curve extraction and classification

A technology of rolling bearings and diagnostic methods, which is applied in the direction of measuring devices, testing of mechanical components, character and pattern recognition, etc., which can solve the problem of inconspicuous fault feature components, increasing the difficulty of fault feature extraction, complex mapping relationship between signal features and fault modes, etc. problems, to avoid installation and reduce equipment downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

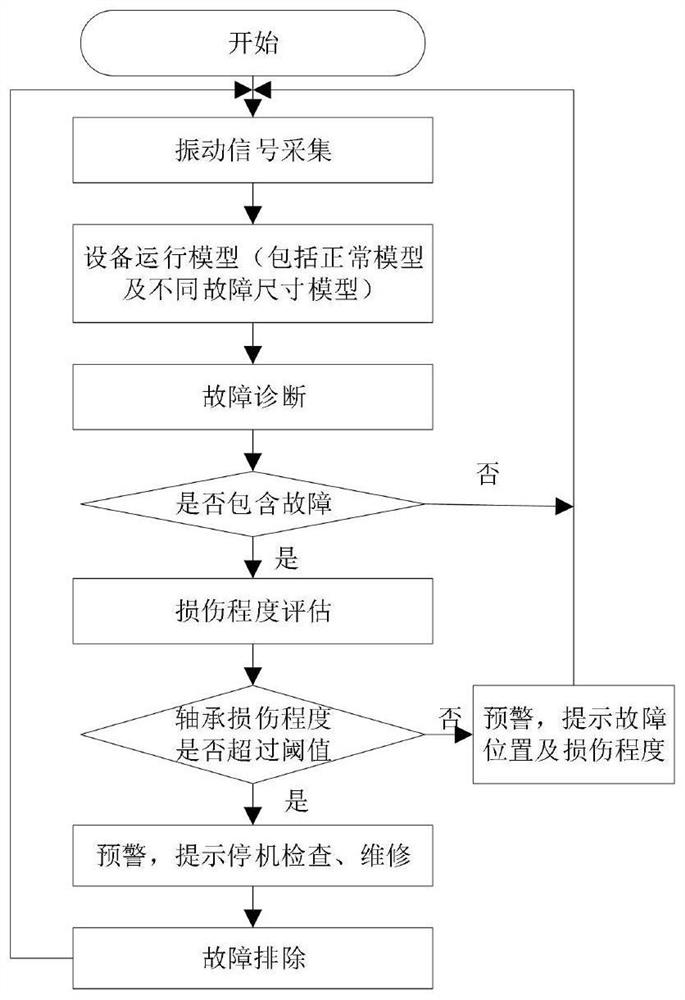

[0039] A method for diagnosing composite faults of rolling bearings under time-varying working conditions based on time-frequency curve extraction and classification, comprising the following steps:

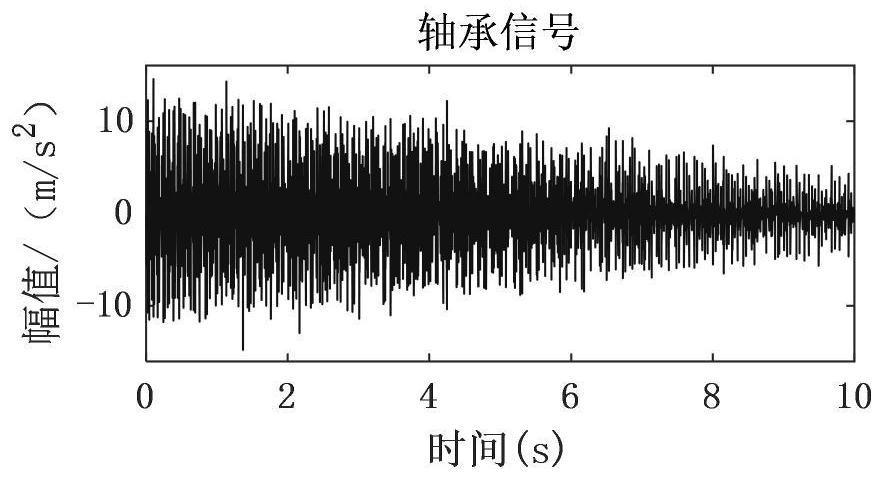

[0040] S1: The composite fault vibration signal of the rolling bearing under the time-varying working condition is collected by the signal acquisition module;

[0041] S2: perform wavelet threshold filtering and denoising on the collected vibration signal through the preprocessing module circuit to realize the noise reduction processing of the signal;

[0042] S3: Perform Hilbert envelope demodulation and short-time Fourier transform on the noise-reduced vibration signal to obtain a time-frequency image;

[0043] S4: use the time-frequency curve extraction algorithm based on fast path optimization to extract the time-frequency curve in the time-frequency image;

[0044] S5: classify the time-frequency curve using the time-frequency curve classification criterion;

[0045] S6: M...

Embodiment 2

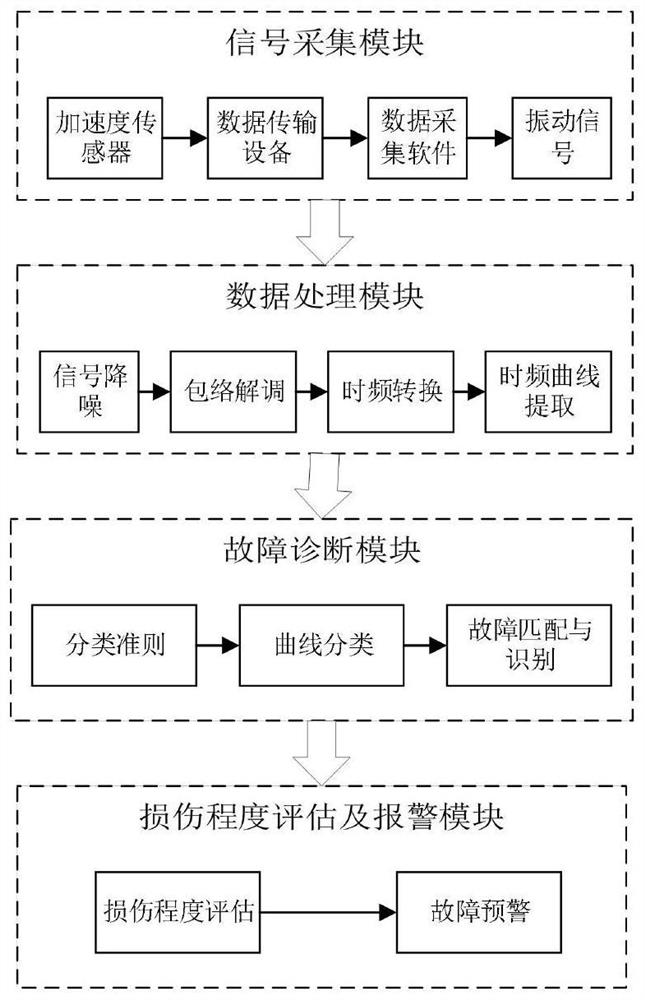

[0058] A time-varying working condition rolling bearing composite fault diagnosis device based on time-frequency curve extraction and classification, comprising:

[0059] The signal acquisition module is used to collect the time-varying working condition compound fault vibration signal through the acceleration sensor, and the acceleration sensor is installed in three directions: axial, radial and vertical;

[0060] The signal preprocessing module is used to preprocess the collected diaphragm pump vibration signal, including signal filtering, demodulation, time-frequency conversion and time-frequency curve extraction, which is convenient for subsequent status identification;

[0061] The fault diagnosis module is used to extract the extracted time-frequency curve for classification using classification criteria, and perform fault matching and identification with the fault characteristic coefficient;

[0062] The damage assessment and early warning module is used to assess the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com