Sheet metal part rectangular contour three-dimensional measurement method and system based on feature fitting

A technology of three-dimensional measurement and sheet metal parts, which is applied in the field of three-dimensional measurement, can solve the problems that it is difficult to guarantee the reconstruction accuracy of the rectangular contour point cloud and the stability of data processing, and achieve the effect of ensuring the reconstruction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

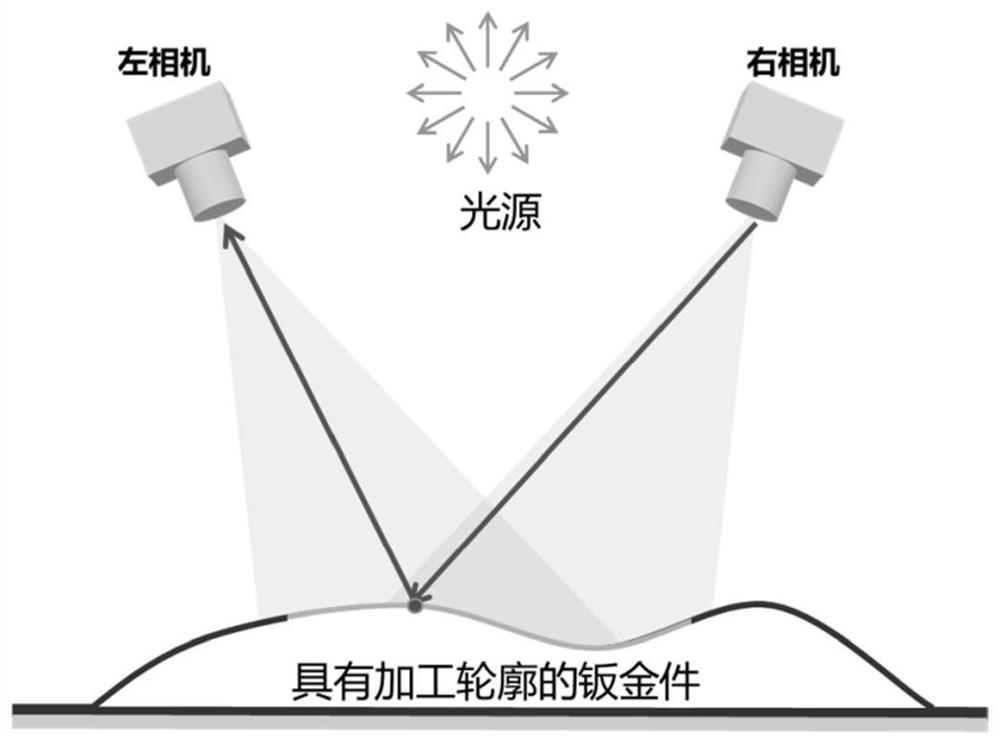

[0058] (1) If figure 2 As shown in the figure, turn on the light source to ensure that the surface of the sheet metal part has proper lighting, and then use the binocular camera to take pictures synchronously to obtain the image of the sheet metal part.

[0059] (2) Perform distortion correction and epipolar correction on the image, and then perform canny edge detection to obtain preliminary edges, perform contour extraction and identification, and obtain rectangular contours.

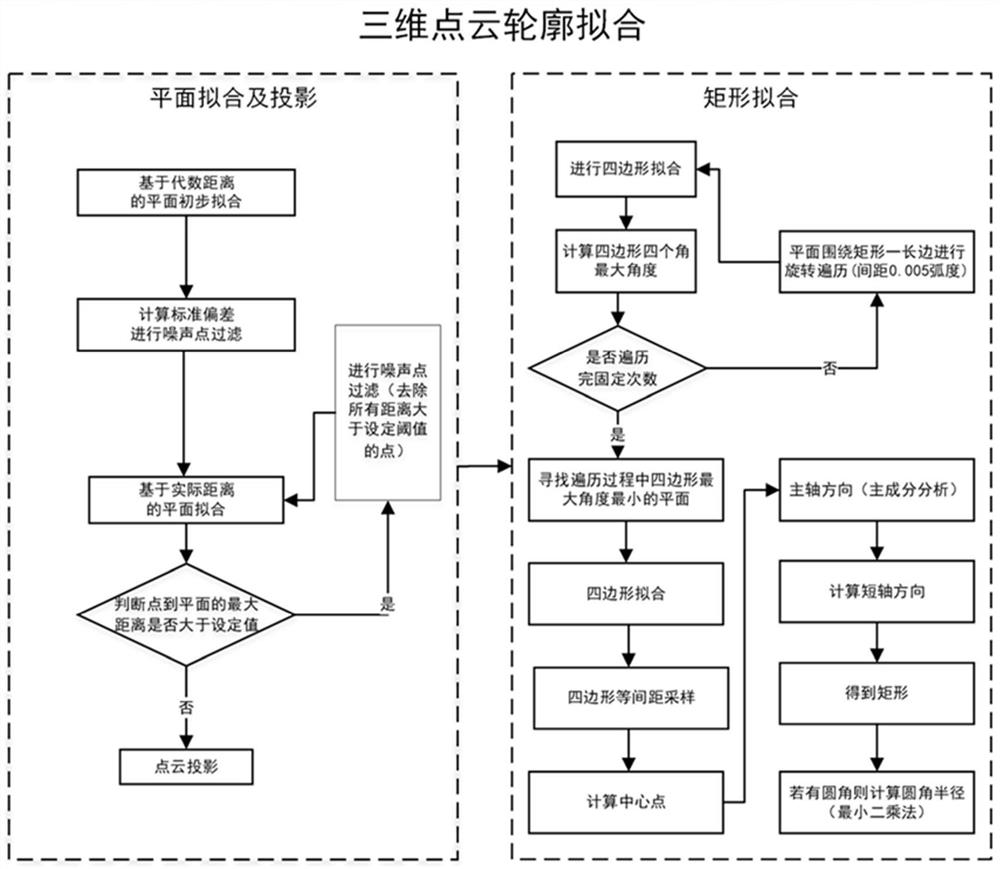

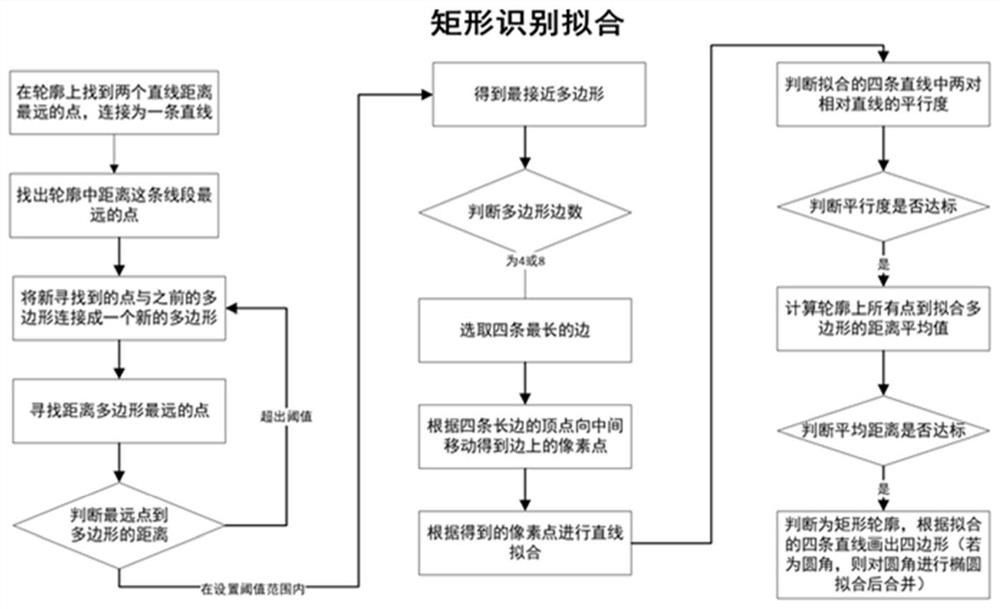

[0060] Specifically, as image 3 As shown, first, based on the ratio of the gray value inside and outside the contour, it is judged whether the requirements for the contour of the rectangular hole position are met, and if so, proceed to the next step; that is, find the closest polygon of the contour, and if the number of sides of the obtained polygon is 4, it is considered that This contour may be a parallelogram; continue to the next step, perform parallelogram judgment, and judge the parallelism of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com