Ampoule bottle opening auxiliary device

An auxiliary device and ampoule technology, which is applied in the field of medical supplies, can solve the problems of accidentally injuring the hands of medical staff, pollution of glass slag, friction and falling off, etc., and achieve the effects of saving time, improving efficiency and reducing elastic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

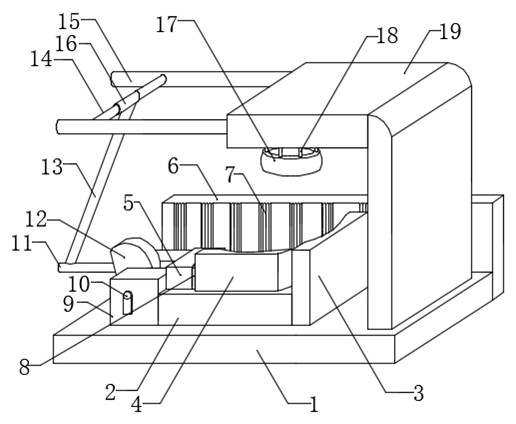

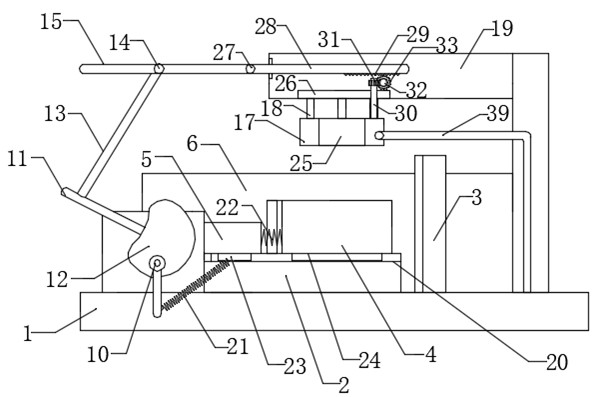

[0029] like figure 1 , figure 2 and Figure 4 As shown, an auxiliary device for opening ampoules includes an engaging mechanism and a grinding mechanism. A bottom plate (1) is mounted on the bottom of the engaging mechanism, a vertical plate is mounted on the top of the bottom plate (1), and a top of the vertical plate is mounted with a The horizontal plate (19) is provided with a grinding mechanism at the bottom of the horizontal plate (19), a bottom plate (1) is installed on the bottom of the engaging mechanism, a fixing block (9) is installed on one side of the bottom plate (1), and the bottom plate (1) A baffle plate (6) is installed on the top of the baffle plate (6), a buffer groove (7) is arranged on the surface of the baffle plate (6), an engaging plate (3) is installed on the other side of the bottom plate (1), and the inner wall of the engaging plate (3) is arc-shaped , a rotating shaft (10) is installed inside the fixed block (9), an arc hammer (12) is rotatably ...

Embodiment 2

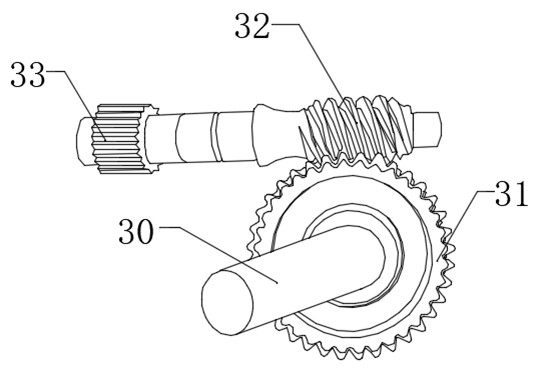

[0035] like figure 1 , figure 2 , image 3 , Figure 5 and Image 6 As shown, an auxiliary device for opening ampoules includes an engaging mechanism and a grinding mechanism. A bottom plate (1) is mounted on the bottom of the engaging mechanism, a vertical plate is mounted on the top of the bottom plate (1), and a top of the vertical plate is mounted with a The horizontal plate (19) is provided with a grinding mechanism at the bottom of the horizontal plate (19),

[0036] A bottom plate (1) is mounted on the bottom of the engaging mechanism, a fixing block (9) is mounted on one side of the bottom plate (1), a baffle plate (6) is mounted on the top of the bottom plate (1), and a surface of the baffle plate (6) is provided with a baffle plate (6). The buffer groove (7), the other side of the bottom plate (1) is provided with a snap plate (3), the inner wall of the snap plate (3) is arc-shaped, and a rotating shaft (10) is installed inside the fixed block (9), and the rotat...

Embodiment 3

[0041] like figure 1 , figure 2 , image 3 , Figure 5 , Image 6 and Figure 7 As shown, an auxiliary device for opening ampoules includes an engaging mechanism and a grinding mechanism. A bottom plate (1) is mounted on the bottom of the engaging mechanism, a vertical plate is mounted on the top of the bottom plate (1), and a top of the vertical plate is mounted with a The horizontal plate (19) is provided with a grinding mechanism at the bottom of the horizontal plate (19),

[0042] A bottom plate (1) is mounted on the bottom of the engaging mechanism, a fixing block (9) is mounted on one side of the bottom plate (1), a baffle plate (6) is mounted on the top of the bottom plate (1), and a surface of the baffle plate (6) is provided with a baffle plate (6). The buffer groove (7), the other side of the bottom plate (1) is provided with a snap plate (3), the inner wall of the snap plate (3) is arc-shaped, and a rotating shaft (10) is installed inside the fixed block (9), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com