Yarn breakage automatic stop system of double-control type ring spinning machine

A ring spinning machine, end-break automatic stop technology, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problem of uneven thickness of finished yarns, to save sliding distance, The effect of increasing the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0032] In the description of the present invention, it should be understood that the terms "center", "longitudinal", "lateral", "length", "width", "thickness", "upper", "lower", "front", " Rear, Left, Right, Vertical, Horizontal, Top, Bottom, Inner, Outer, Clockwise, Counterclockwise, Axial, The orientations or positional relationships indicated by "radial direction", "circumferential direction", etc. are based on the orientations or positional relationships shown in the accompanying drawings, which are only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying the indicated devices or elements. It must have a specific orientation, be constructed and operate in a specific orientation, and therefore should not be construed as a limitation of the present invention.

[0033] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be furthe...

Embodiment 1

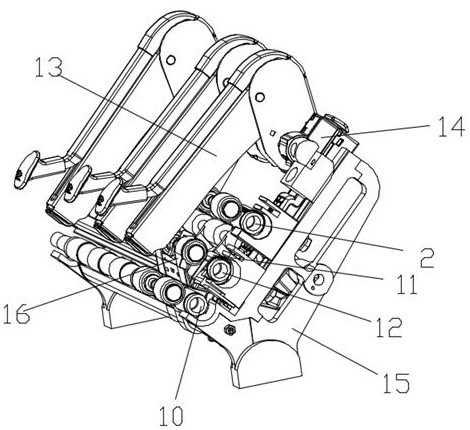

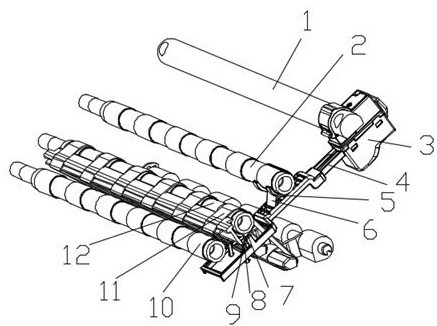

[0036] like figure 1 Shown: a group of rollers are fixed on the frame 15 of the ring spinning frame, including the front roller 10, the middle roller 12 and the back roller 2, the front roller 10, the middle roller 12 and the back roller 2 are fixed above the head assembly 13 , the bottom of the indenter assembly 13 is provided with the front roller 10, the top of the middle roller 12 and the rear roller 2 is fixed with a press roller corresponding to the indenter assembly 13, the middle roller 12 is provided with a lower belt 10, corresponding to the middle roller There is an upper belt 16 on the pressing roller, and the yarn passes between the pressing roller and the roller. At the middle roller, the yarn passes through the direct contact surface of the lower belt 10 and the upper belt 16; the upper part of the frame 15 is fixed with a drive Component 3, such as figure 2 As shown, the drive assembly 3 is connected with a push plate 4, the push plate 4 is provided with a nu...

Embodiment 2

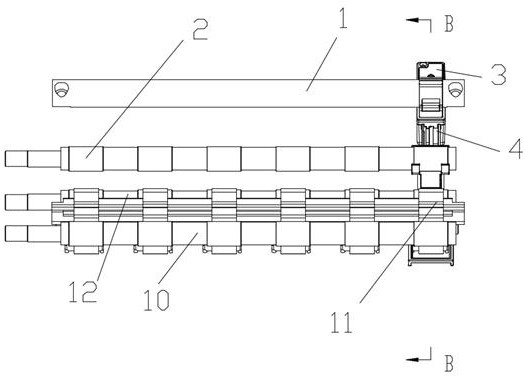

[0045] like Figure 5 As shown, on the basis of Embodiment 1, the drive assembly 3 is connected with a push plate 4, and the push plate 4 is provided with a number of rectangular grooves arranged in a straight line. The first support plate 6 and the second support plate 9 are connected, the upper end of the first support plate 6 is hinged with the first arc wedge 5 through the first hinge point 801, and the second support plate 9 is hinged with the first hinge point 8. The second arc-shaped wedge 7 and the first arc-shaped wedge 5 are clipped on the back roller, and the second arc-shaped wedge is clipped on the middle roller and located under the lower belt 10 .

[0046] The specific use method is the same as that of the first embodiment, and will not be repeated here. The difference is that the second embodiment, as shown in Image 6 As shown, since the arc-shaped wedge and the support plate are connected in a hinged manner, the limit positions of the first support plate 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com