Sample clamp and test method

A testing method and sample technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of easy falling off, low efficiency, long time consumption, etc., and achieve the effects of accurate testing results, stable and convenient analysis, and avoiding sample damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

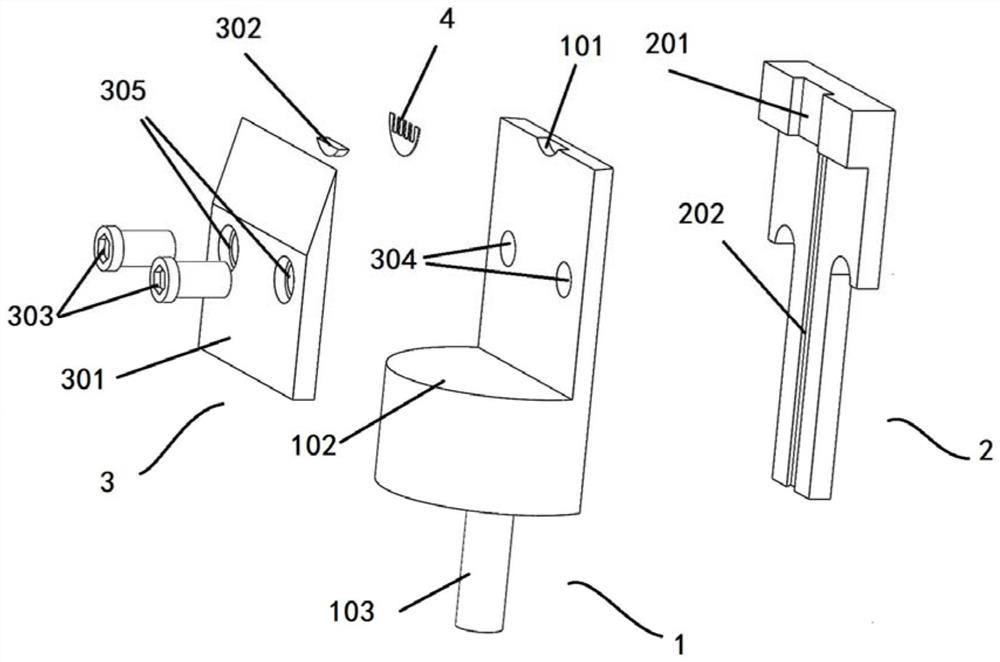

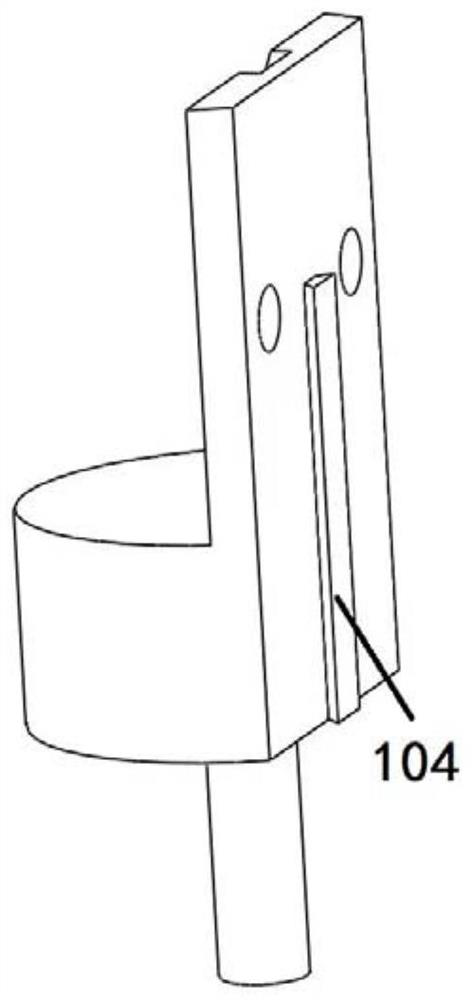

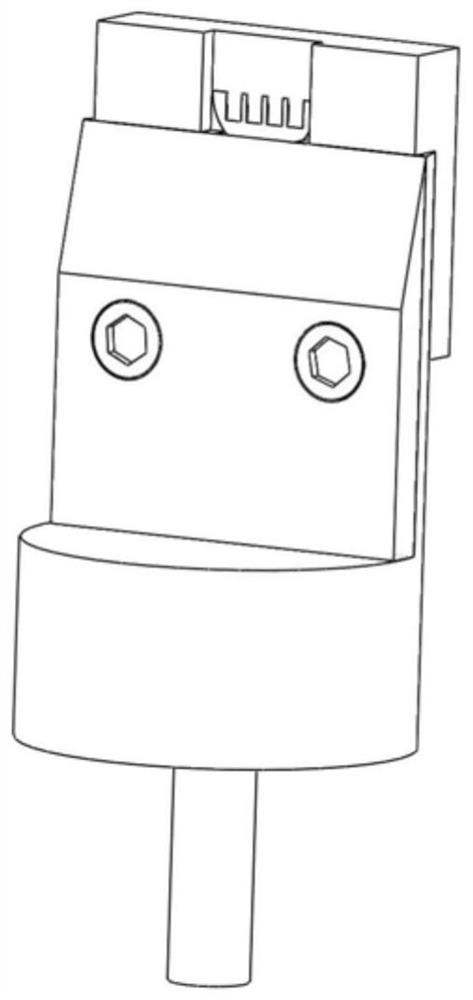

[0042] This example provides sample holders such as figure 1 As shown, it includes a base 1, the base 1 is provided with a groove 101, and the depth of the groove 101 is smaller than the height of the sample stage 4 to expose the bearing part of the sample stage 4; the guide structure 2 is detachably installed on the base 1 The guide structure 2 has a chute 201 communicated with the groove 101 and a support plate attached to one side of the base 1 . The chute 201 is suitable for guiding the sample carrier 4 to slide into the groove 101 under the action of gravity. The sample holder in this embodiment is a FIB-t-EBSD combined sample holder.

[0043] The sample stage 4 slides to the groove 101 through the chute 201 on the guide structure 2 , and the chute 201 makes the height of the sample stage 4 horizontal during installation to prevent the sample stage 4 from falling off and deforming during installation. The guide structure 2 is detachably installed, and the depth of the gr...

Embodiment 2

[0055] The present embodiment provides a combined testing method for FIB-t-EBSD, using the sample holder in Example 1, including the following steps:

[0056] 1. Place the sample stage 4 into the groove 101 of the base 1 through the chute 201 of the guide structure 2, specifically including:

[0057] After placing the sample stage 4 on the chute 201 of the horizontally arranged guide structure 2, the guide structure 2 is then tilted from a horizontal position to a position at an angle of 40-50° with the horizontal plane, in this embodiment, tilted to 45°, so that The sample stage 4 slides into the groove 101 along the chute 201 under the action of gravity. After the sample carrier 4 slides into the groove 101, the sample carrier 4 is fixed on the base by using the pressing block 301 and the fixing structure 3, such as image 3 shown.

[0058] Remove the guide structure 2 as in Figure 4 As shown, the sample holder assembled with the sample stage 4 is installed on the specia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com