Supporting structure for semiconductor detection

A support structure and semiconductor technology, which is applied in the field of semiconductors, can solve the problems of measurement work influence, inaccurate measurement values, semiconductor damage, etc., and achieve the effect of increasing friction, reducing pressure, and facilitating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

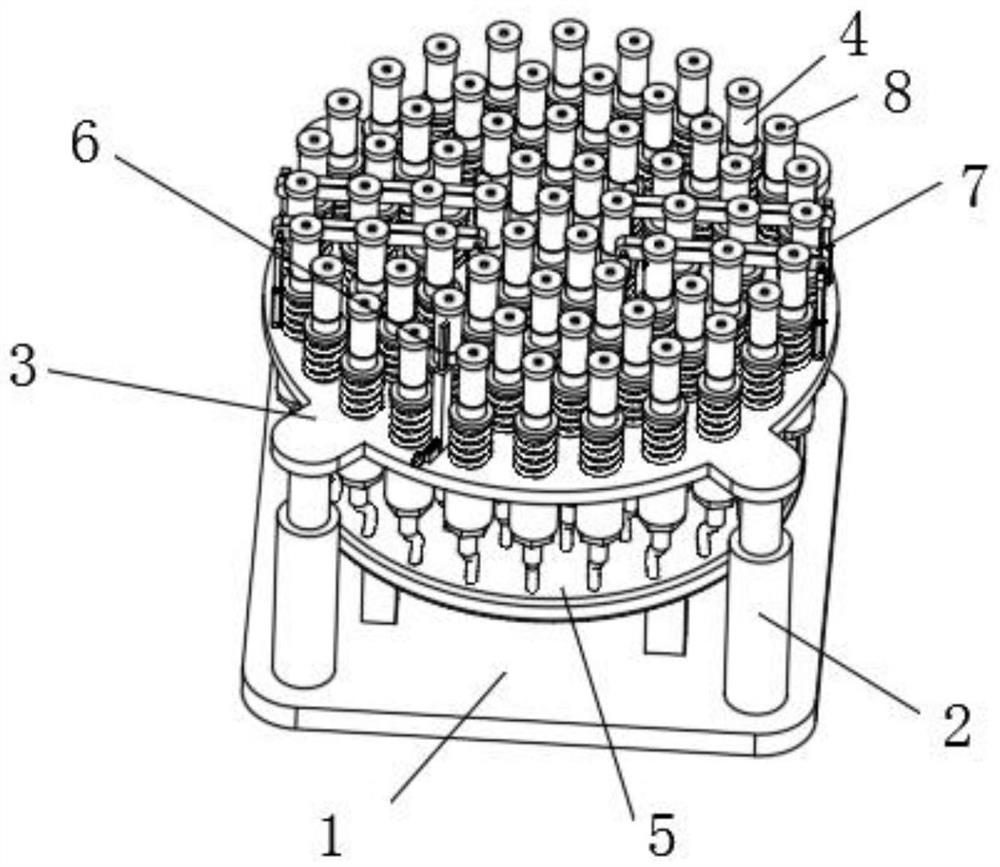

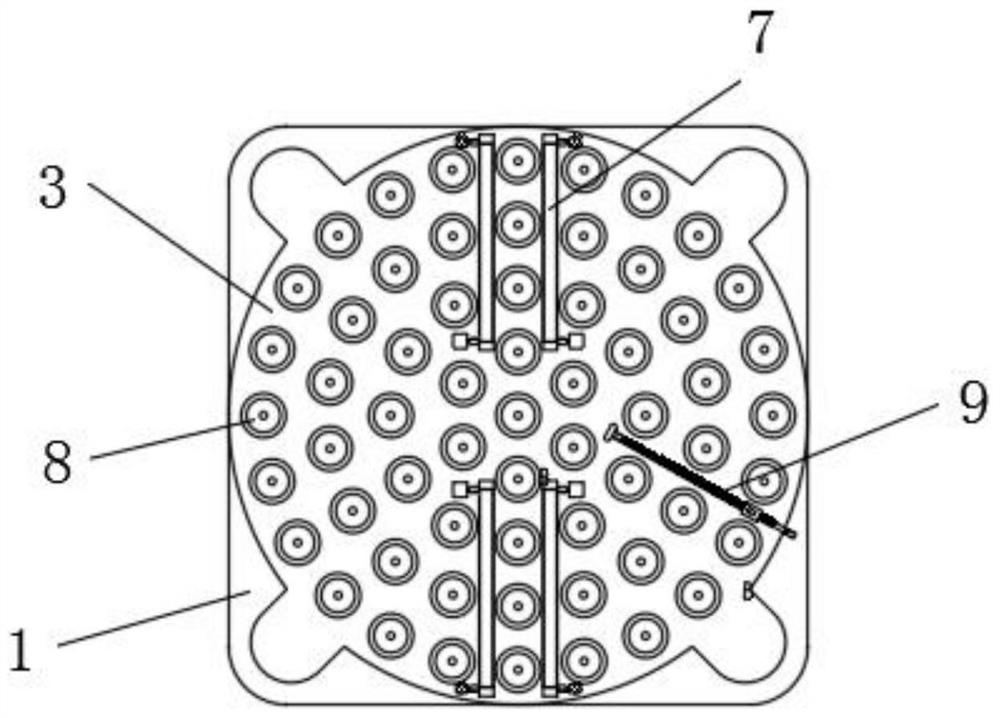

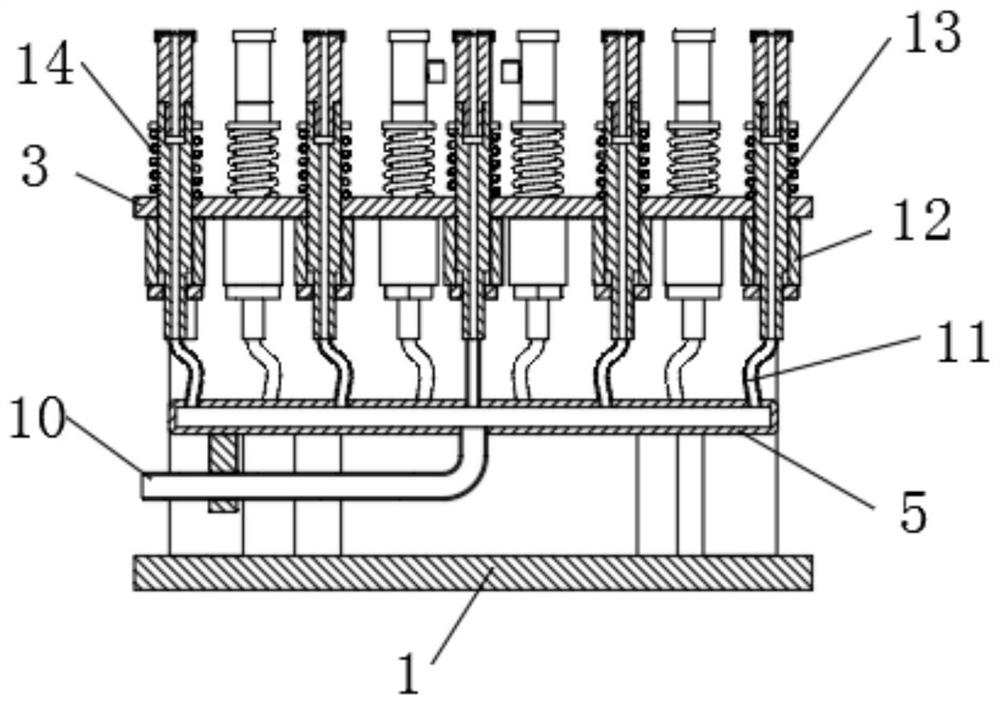

[0042] Example: Reference Figure 1-8 The shown support structure for semiconductor inspection includes a base plate 1, a fixed plate 3 is installed on the top side of the base plate 1 through a plurality of first telescopic rods 2, and a plurality of sliding holes 25 are opened on the fixed plate 3. 25 are slidably installed with pop-up units, the top sides of multiple pop-up units are located on the same plane, the top side of the fixed plate 3 is installed with a positioning rod 6 through an adjustment mechanism, and the top side of the fixed plate 3 is installed with a lifting mechanism. The material moving rod 21, the positioning rod 6 and the plurality of material moving rods 21 are located at the gaps of the plurality of ejector units; the ejector unit includes a sliding column 13, and the sliding column 13 is slidably installed in the corresponding sliding hole 25, and the sliding column 13 and An elastic unit is installed between the fixed disks 3 , a support column 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com