Gas distribution disc, combustor and gas stove

A gas distribution plate and gas distribution channel technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve the problems of uneven heating of the bottom of the pot, uneven heating of ingredients, and failure to meet heating needs, so as to improve heating Uniformity, the effect of reducing cumbersomeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

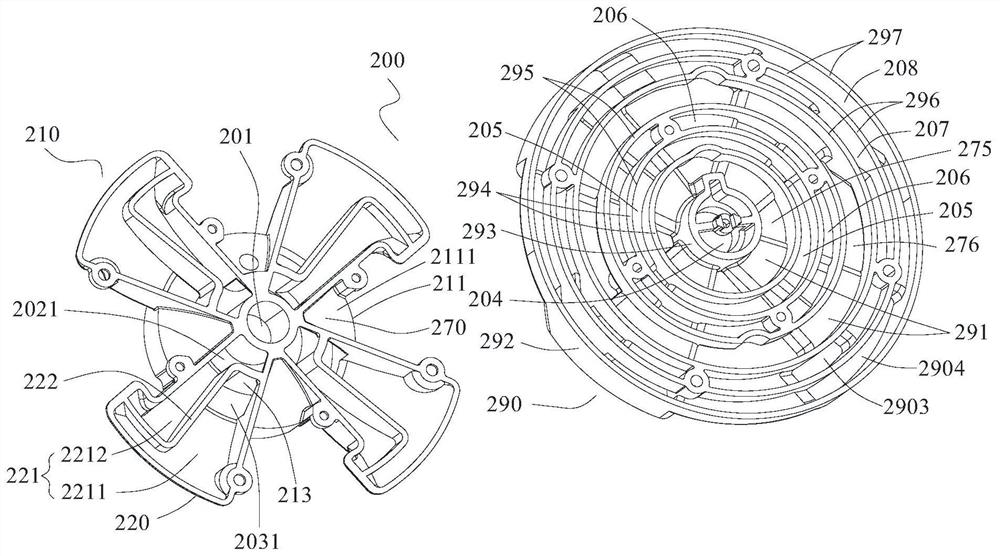

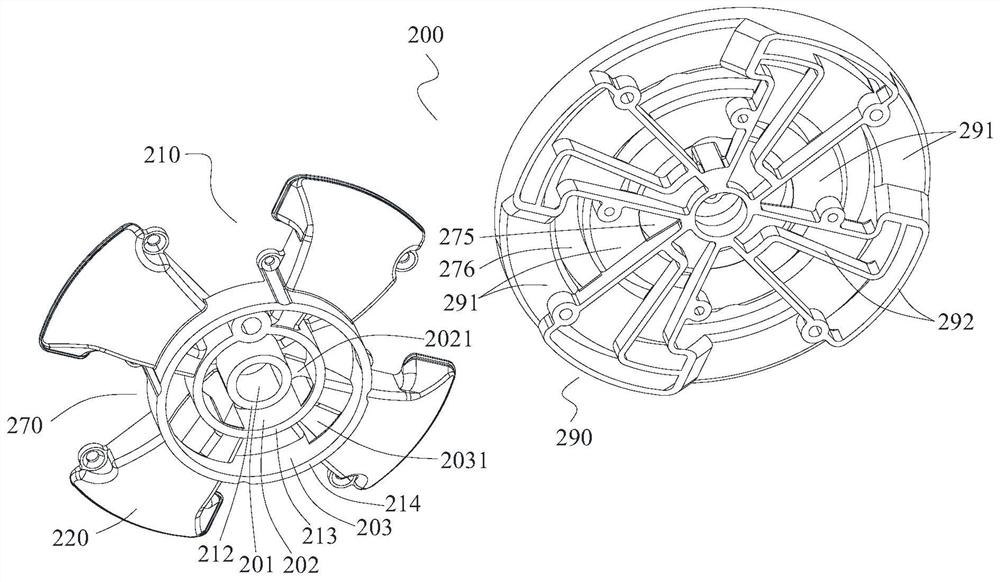

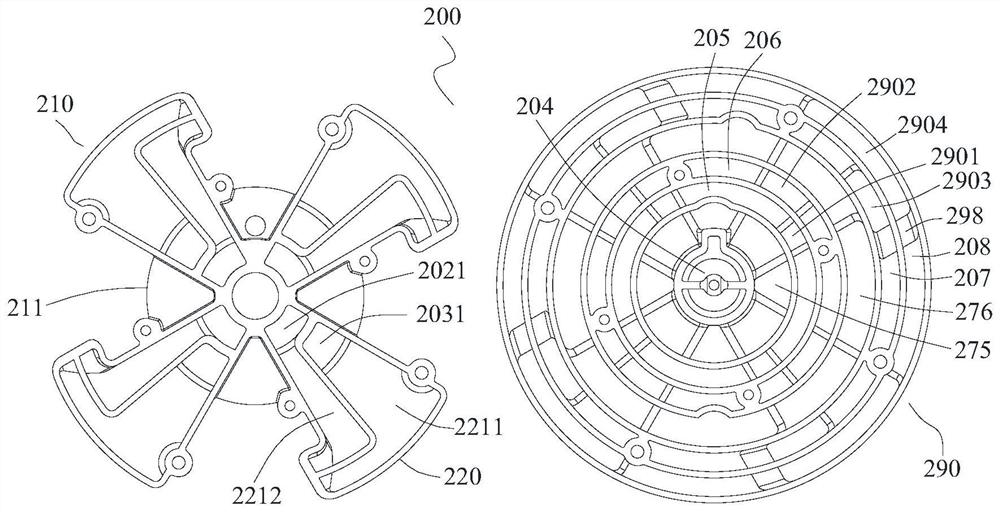

[0039] The following description and drawings sufficiently illustrate the specific embodiments herein to enable those skilled in the art to practice them. Portions and features of some embodiments may be included in or substituted for those of other embodiments. The scope of the embodiments herein includes the full scope of the claims, along with all available equivalents of the claims. Herein, the terms "first," "second," etc. are only used to distinguish one element from another, and do not require or imply any actual relationship or order between the elements. In fact the first element can also be called the second element and vice versa. Furthermore, the terms "comprising", "comprising" or any other variation thereof are intended to encompass a non-exclusive inclusion such that a structure, device or device comprising a list of elements includes not only those elements, but also others not expressly listed elements, or elements inherent to such structures, devices, or eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com