Black tea instant powder rich in theaflavin as well as preparation method and application of black tea instant powder

The technology of instant powder and theaflavin is applied to the instant powder of black tea rich in theaflavin and the field of preparation thereof, which can solve the problems of inappropriate extraction and processing technology, excitation of the central nervous system, low content of theaflavin and the like, and achieve effective The effect of complete retention of ingredients, low caffeine content, and high theaflavin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

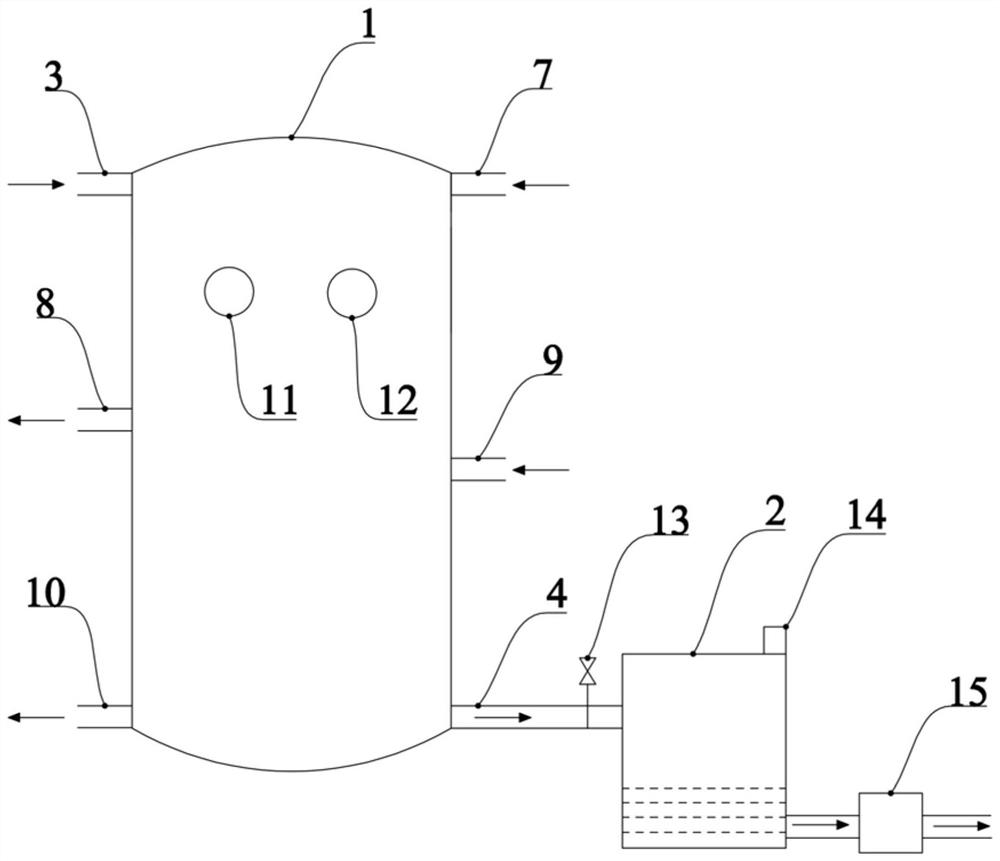

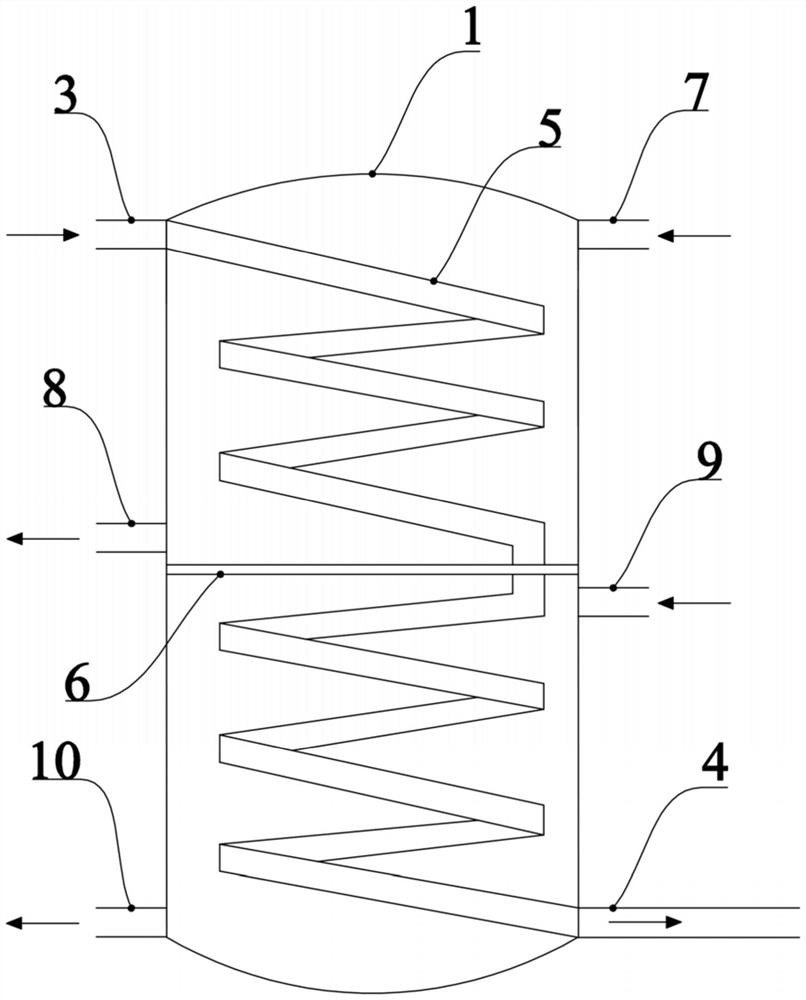

Method used

Image

Examples

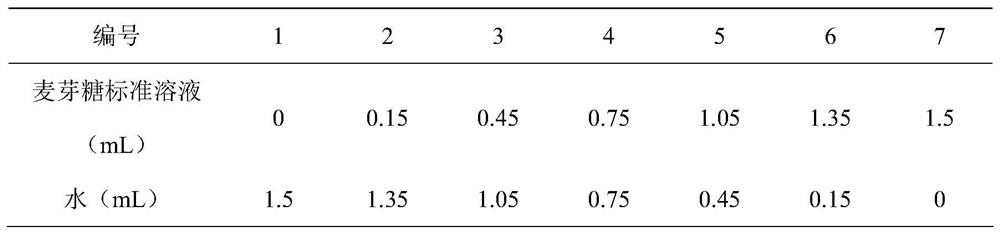

Embodiment 1

[0064] 100kg of black tea (theaflavin content 0.71%, caffeine content 3.1%) was pulverized and passed through an 80 mesh sieve, 25 times the amount of medicinal materials was added with purified water at room temperature, and the mixture was continuously stirred. The extraction takes about 12 seconds. After the extraction is completed, use plate and frame pressure filtration. The temperature of the filtrate is about 60°C, and the filtrate is filtered through a 100nm ceramic membrane. Then use the built-in 10kDa molecular weight ultrafiltration membrane equipment for ultrafiltration. Collect the ultrafiltration effluent and spray dry it. , wherein the inlet air temperature is 180°C and the outlet air temperature is 90°C, 8.6kg of black tea instant powder is obtained, and the product yield is 8.6%. The theaflavin content is 6.5% and the caffeine content is 3.4% by high performance liquid chromatography.

Embodiment 2

[0066] 100kg of black tea (theaflavin content 0.62%, caffeine content 2.9%) was pulverized through an 80 mesh sieve, 30 times the amount of medicinal materials was added with room temperature purified water, and the mixture was continuously stirred. Extraction for about 15s, after the extraction is completed, use plate and frame pressure filtration, the temperature of the filtrate is about 60 ℃, pass through a 200nm ceramic membrane for fine filtration, and then use the built-in 10kDa molecular weight ultrafiltration membrane equipment for ultrafiltration, collect ultrafiltration effluent, spray dry, The air inlet temperature is 180°C and the outlet air temperature is 90°C, and 8.2kg of black tea instant powder is obtained. The product yield is 8.2%. The theaflavin content is 5.9% and the caffeine content is 3.2% by high performance liquid chromatography.

Embodiment 3

[0068] 100kg of black tea (theaflavin content 0.73%, caffeine content 2.9%) was pulverized through an 80 mesh sieve, 30 times the amount of medicinal materials was added with purified water at room temperature, and the mixture was continuously stirred. Extraction for about 15s, after the extraction is completed, use plate and frame pressure filtration, the filtrate temperature is about 60 ℃, pass through a 200nm ceramic membrane for fine filtration, and then use the built-in 5kDa molecular weight ultrafiltration membrane equipment for ultrafiltration, collect ultrafiltration effluent, spray dry, The air inlet temperature is 180°C and the air outlet temperature is 90°C, 10.4kg of black tea instant powder is obtained, and the product yield is 10.4%. The theaflavin content is 5.5% and the caffeine content is 3.5% by high performance liquid chromatography.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap