Industrial papermaking wastewater treatment device

A technology for papermaking wastewater and treatment devices, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as blockage of filter mechanisms, unfavorable sewage treatment operations, and impact on papermaking wastewater treatment, so as to increase density and improve The effect of the filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

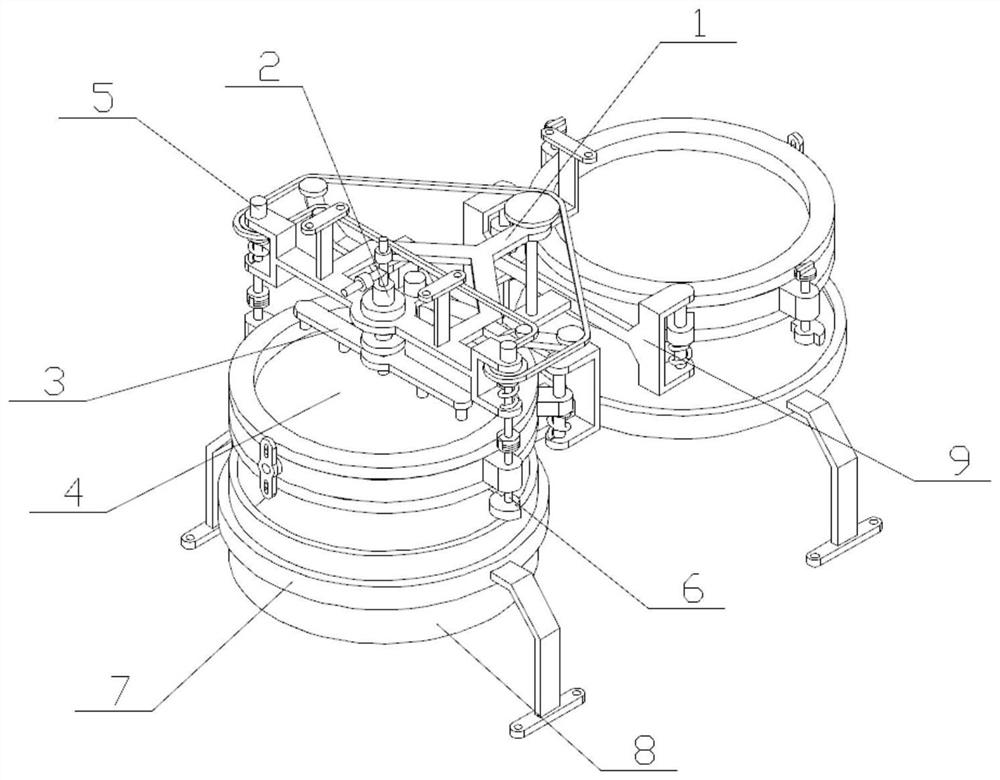

[0037] Combine below Figure 1-8 Describe the specific embodiment of the present invention, an industrial papermaking wastewater treatment device, comprising an upper support assembly and a lower support assembly 7;

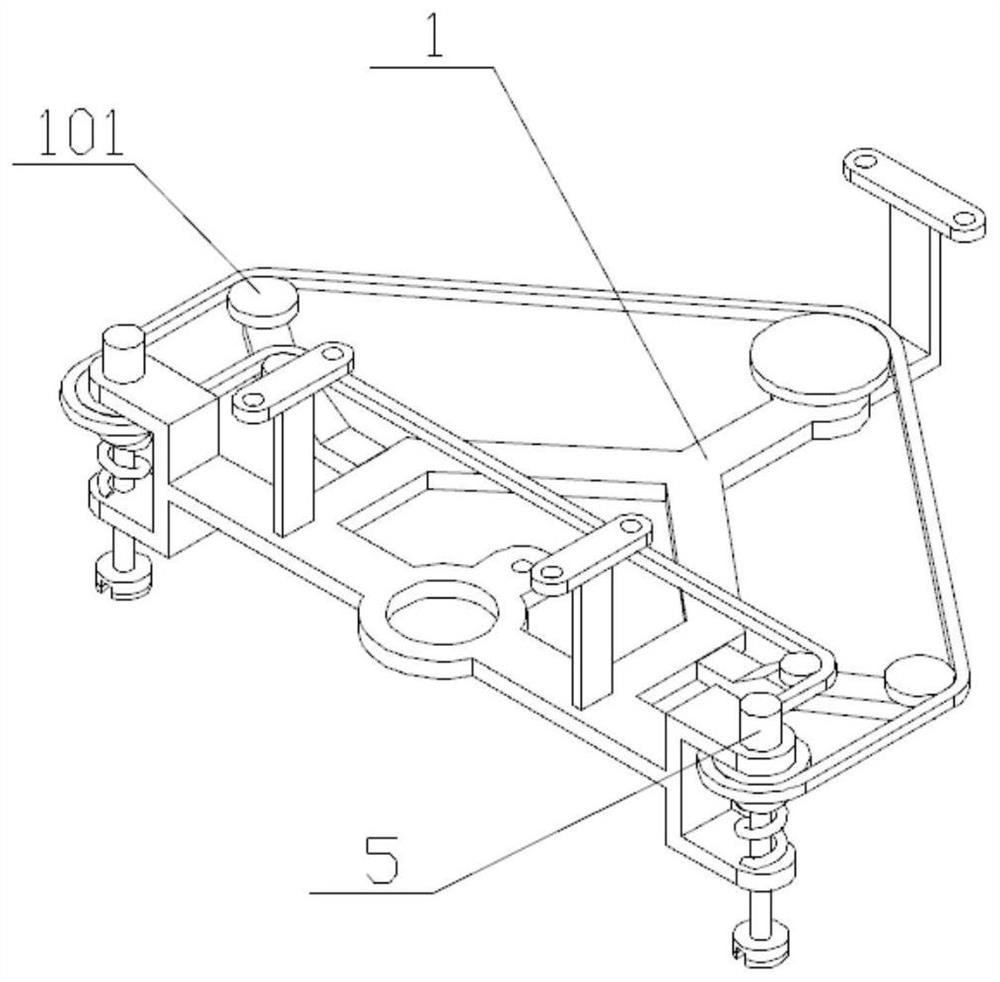

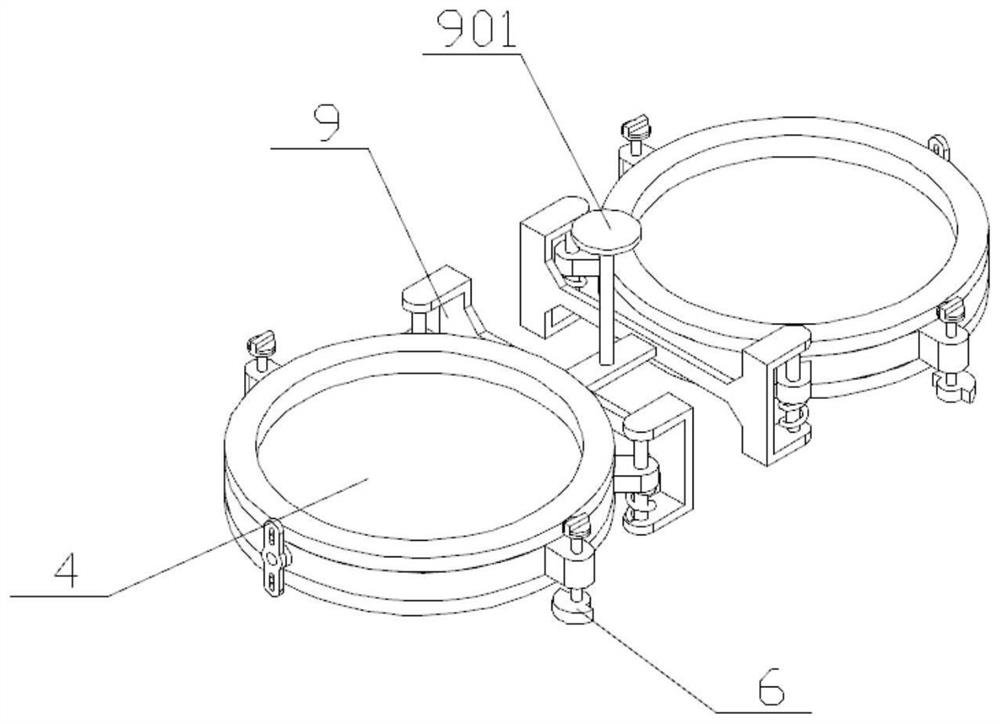

[0038] The screen assembly 4 is connected to the upper support assembly, and the vibration assembly 6 is also rotatably connected to both sides of the screen assembly 4; the left and right sides of the upper support assembly are connected to the drive assembly 5. There is a transmission connection between the drive assembly 5 and the vibration assembly 6; the middle part of the front side of the upper support assembly is also fixedly installed with a connecting assembly 2, and the connecting assembly 2 is connected to the side close to the screen assembly 4 with a rotating shower head 3;

[0039] A collection box 8 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com