Numerical control machine tool cooling liquid filtering device

The technology of a filtering device and a numerically controlled machine tool, which is applied in the field of numerically controlled machine tools, can solve the problems that impurities are difficult to move down, affect the use of the device, and filter, etc., and achieve the effect of convenient separation and reduction of frictional force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

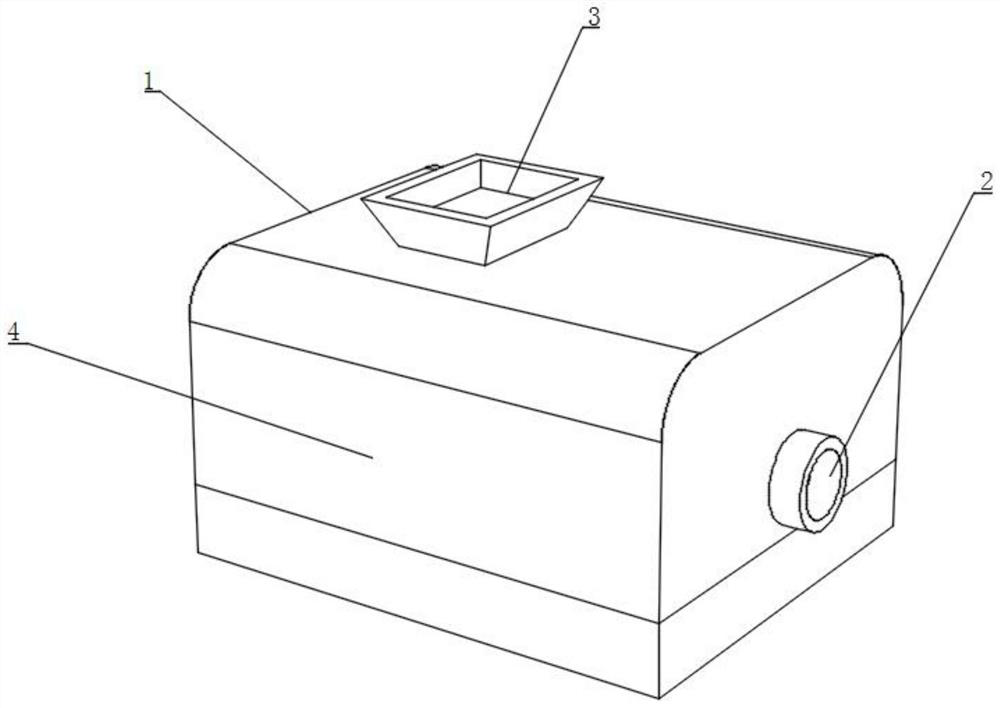

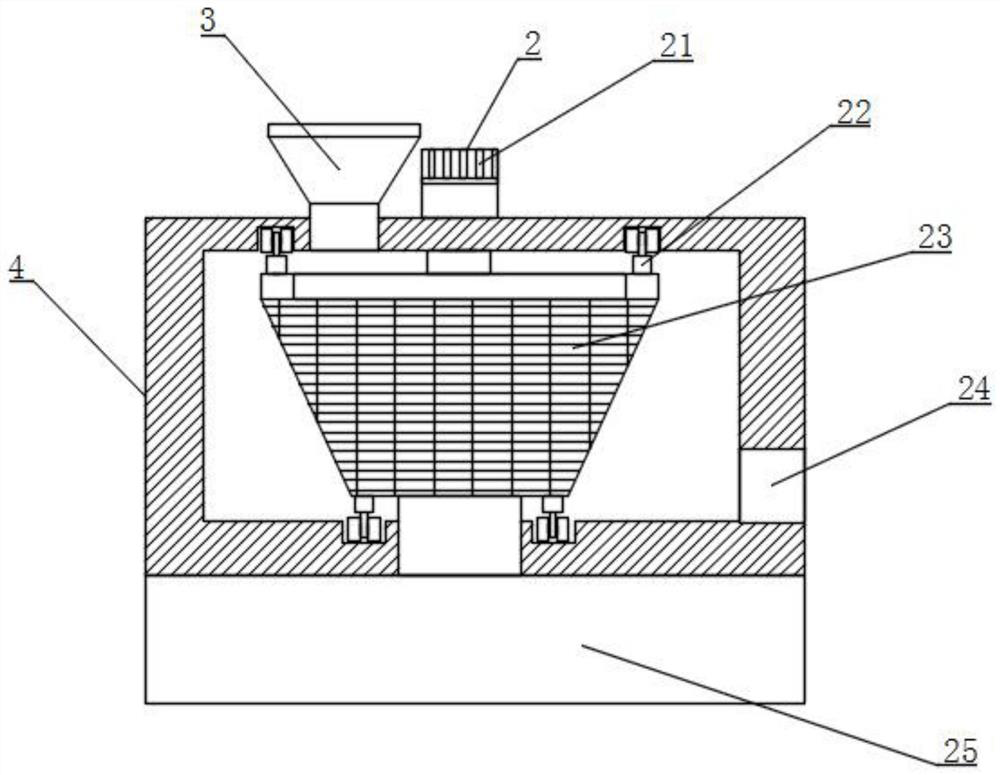

[0031] like Figure 1-6 As shown, the present invention provides a cooling liquid filtering device for a numerically controlled machine tool, a filtering device main body 1, and the filtering device main body 1 includes a pressure-resistant casing 4, and the pressure-resistant casing 4 is provided with a water throwing device 2 inside. The top of the shell 4 is provided with a scraping device 3, the water throwing device 2 includes a motor one 21, the bottom of the motor one 21 is fixedly connected with the top of the pressure-resistant casing 4, and the output shaft of the motor one 21 is fixedly connected with a filter cartridge assembly 23 , one side of the filter cartridge assembly 23 is provided with a squeezing wheel 22, the scraping device 3 includes a water inlet pipe 31, the bottom of the water inlet pipe 31 is fixedly connected with the top of the pressure-resistant casing 4, and one side of the inner wall of the water inlet pipe 31 is fixedly connected There is a se...

Embodiment 2

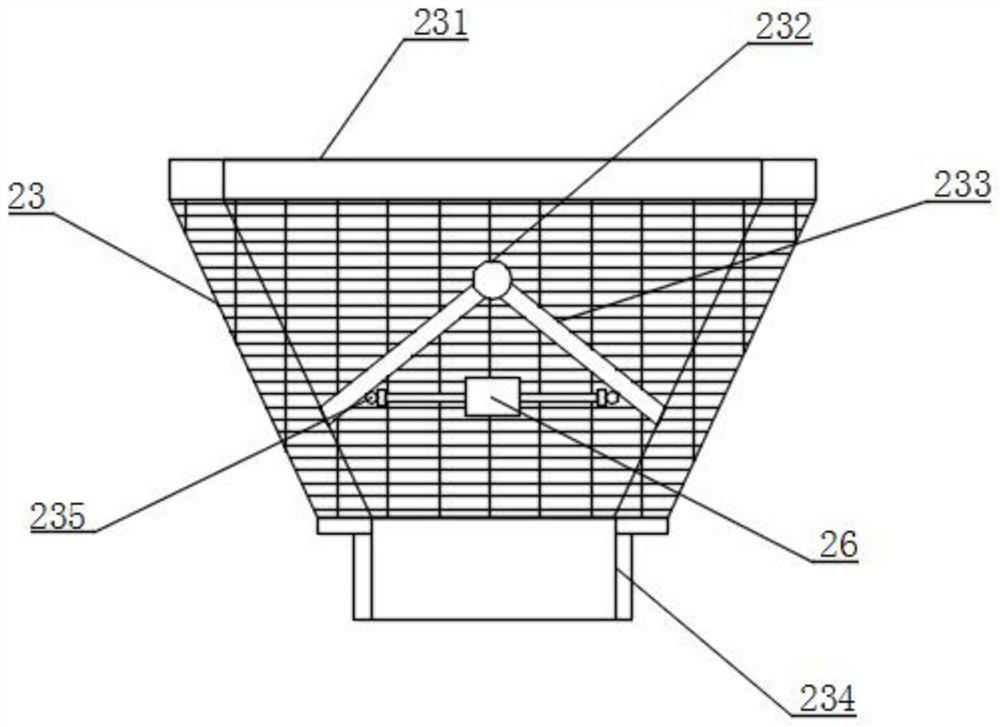

[0033] like Figure 1-6As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the filter cartridge assembly 23 includes a filter screen tube 231, the inner wall of the filter screen tube 231 is fixedly connected with a rotating rod 232, and the outer wall of the rotating rod 232 is fixed A rotating rod 233 is connected, the bottom inner wall of the rotating rod 233 is fixedly connected with a bidirectional rotating shaft 235, the bottom of the filter tube 231 is fixedly connected with the extrusion device 26, and the bottom of the filter tube 231 is fixedly connected with a conveying pipe 234, through the filter cartridge assembly 23 pair The cooling liquid is filtered and separated, the cooling liquid thrown out by the filter cartridge assembly 23 flows out through the water outlet 24, and the residue enters the interior of the collection box 25 through the bottom of the filter cartridge assembly 23 for collection, which facili...

Embodiment 3

[0035] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the extrusion device 26 includes a pressure-resistant casing 261, and the inner wall of the pressure-resistant casing 261 is fixedly connected with a sliding rod 262, and the sliding rod The outer wall of 262 is movably connected with an iron block 263, one side of the iron block 263 is rotatably connected with an extrusion rod 1 264, and the other end of the extrusion rod 1 264 is movably connected with an extrusion rod 2 265, the extrusion rod 1 264, the extrusion rod One end of the second rod 265 is fixedly connected with one side of the outer wall of the two-way rotating shaft 235, and the outer wall of the iron block 263 is fixedly connected with a spring frame 266. When impurities and coolant enter the interior of the filter cartridge assembly 23, the iron block is pulled by the elastic force of the spring frame 266. 263, so that the extrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com