Multi-stage cascade continuous solid adsorption carbon capture system and operation method

A technology of solid adsorption and carbon capture, applied in separation methods, pipeline systems, chemical instruments and methods, etc., can solve problems such as poor economy, achieve the effects of improving effectiveness, promoting regeneration, and reducing regeneration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

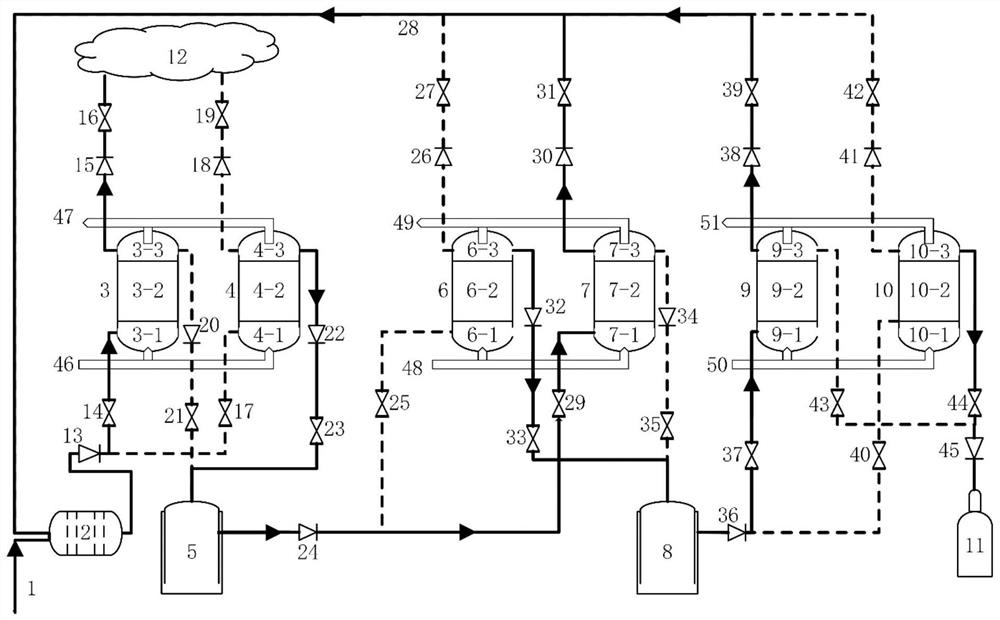

[0045] see figure 1 , In one embodiment, a multi-stage cascade continuous solid adsorption carbon capture system includes a mass recovery unit 2, an enrichment part, a separation part, a purification part, an application unit 11 and an industrial waste heat conduction part.

[0046] Wherein, the input end of the mass return unit 2 is communicated with the inlet pipe 1 for receiving carbon-containing gas.

[0047] The input end of the enrichment part communicates with the output end of the mass return unit 2, and the purified gas output end of the enrichment part communicates with the external atmosphere 12 for receiving carbon-containing gas, adsorbing carbon dioxide in the carbon-containing gas and temporarily storing it. The input end of the separation part is communicated with the carbon adsorption gas output end of the enrichment part, and the purified gas output end of the separation part is communicated with the input end of the mass return unit 2 for receiving the carbo...

Embodiment 2

[0081] This embodiment provides an operation method, which is applied to the multi-stage cascade continuous solid adsorption carbon capture system in the above-mentioned first embodiment, as follows:

[0082] The first working mode: open the first inlet valve 14 and / or the second inlet valve 17 and the first enrichment exhaust valve 16 and / or the second enrichment exhaust valve 19, so that the compound gas generated by the recovery unit 2 is The carbon dioxide is stored by the material in the first filling unit 3-2 and / or the second filling unit 4-2, and the gas impurities are directly discharged through the first enrichment exhaust valve 16 and / or the second enrichment exhaust valve 19;

[0083] After the enrichment unit is stored, the first inlet valve 14 and / or the second inlet valve 17 and the first enrichment exhaust valve 16 and / or the second enrichment exhaust valve 19 are closed.

[0084] Second working mode: open the third enriched exhaust valve 21 and / or the fourth e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap