Uniform and stable ceramic precursor sol preparation device

A technology for ceramic precursors and preparation devices, which is applied in mixers with rotating stirring devices, dissolving, transporting and packaging, etc., can solve the problems of insufficient stirring, uneven mixing of raw materials, and inability to accurately control pH value, etc. The effect of collision probability, uniform distribution and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

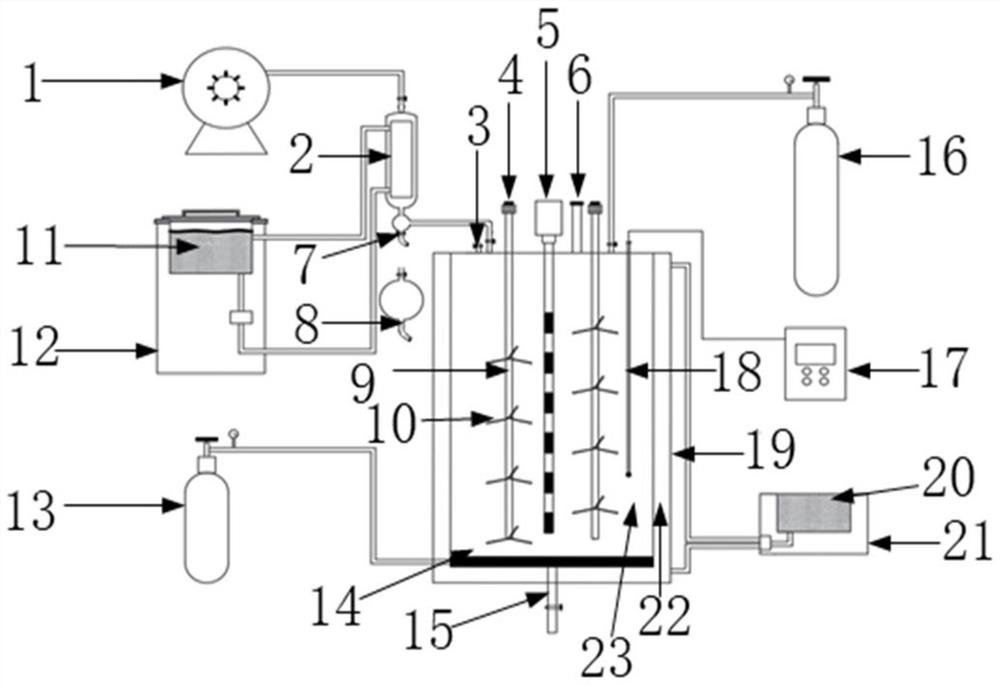

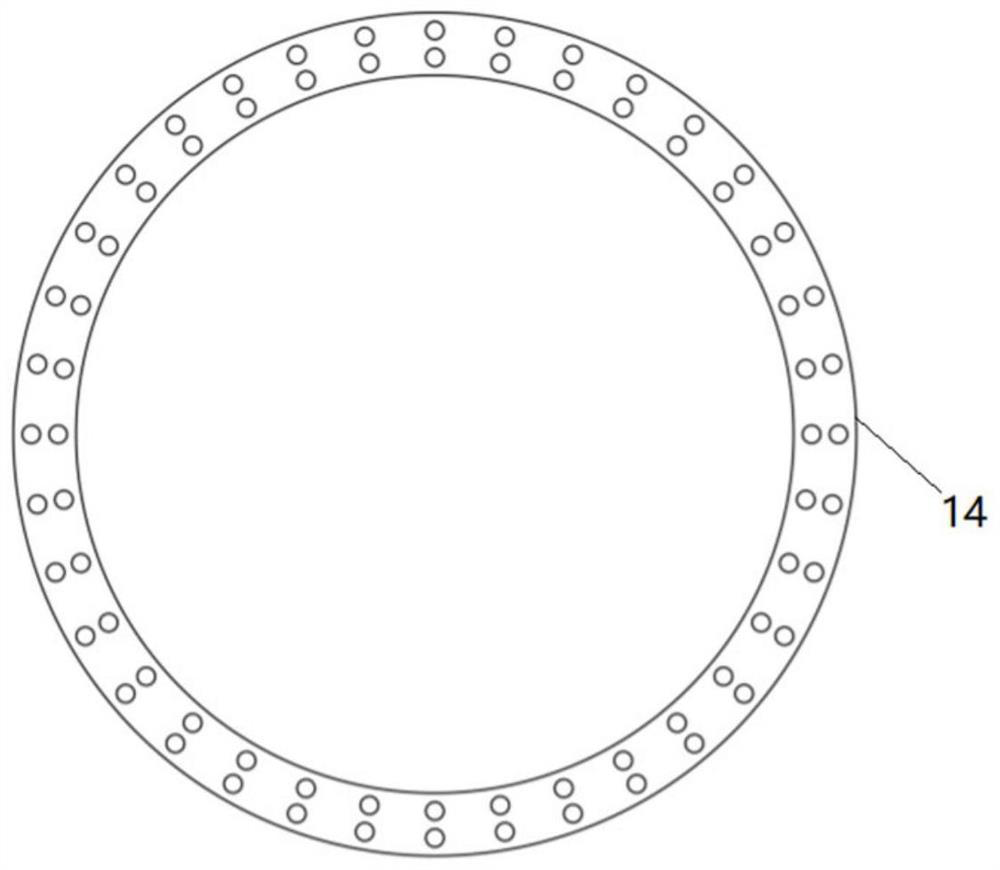

[0042] In order to achieve precise control of temperature and pH value and to be able to prepare a spinnable ceramic precursor sol, and to provide a spinnable ceramic precursor sol for subsequent dry spinning, this embodiment provides a uniform and stable ceramic precursor sol. Preparation device, the structure of which can be found in figure 1 shown, wherein the double-layer reactor 19 is divided into a double-layer reactor inner layer 23 and a double-layer reactor outer layer 22, and arranged in the double-layer reactor inner layer 23 are the ultrasonic unit 5, the jet plate 14, the sensor 18 and the stirring Unit; connected with the inner layer 23 of the double-layer reactor, pressurizing equipment and condenser pipe 2; connected with the outer layer 22 of the double-layer reactor is the high-low temperature unit 21; connected with the condenser pipe 2 is the suction unit 1 and Circulating cooling assembly 12 .

[0043] See figure 1 As shown, the double-layer reactor 19 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com