Roundness correction device for circular tube and continuous extrusion winding and unwinding system for circular tube

A correction device and round tube technology, which is applied in the field of equipment manufacturing, can solve the problems of poor roundness and reduced dimensional accuracy of round aluminum tubes, and achieve the effects of avoiding bending deformation and having a novel and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

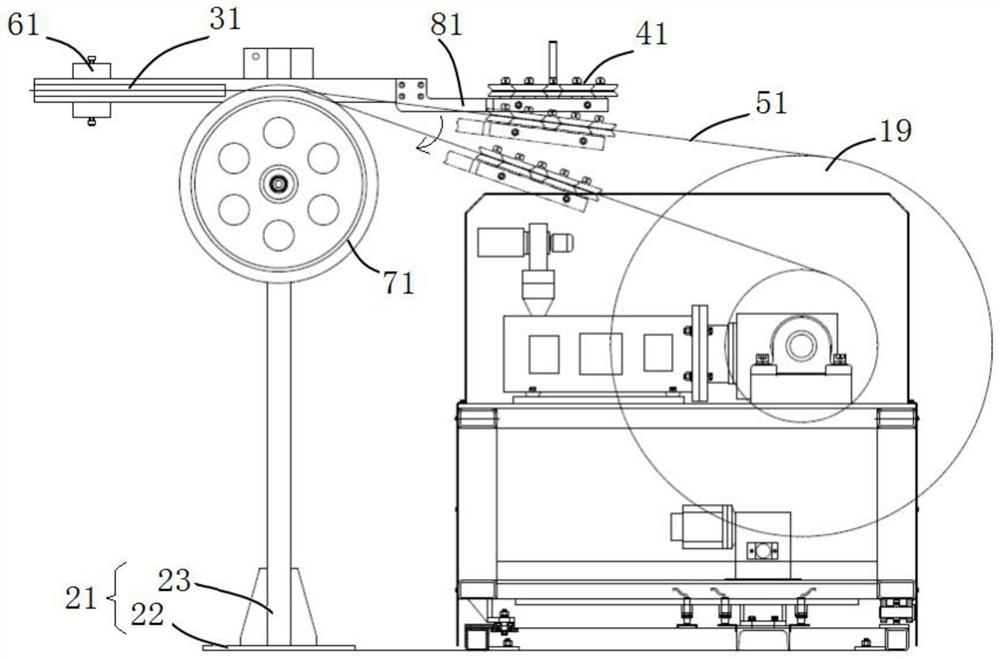

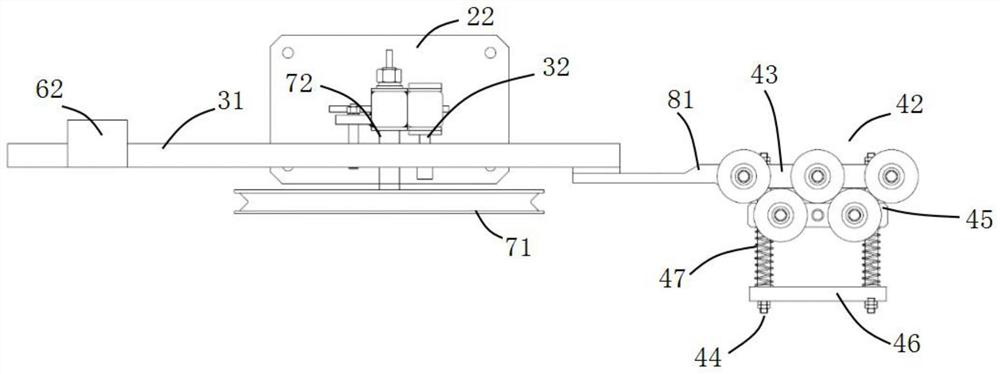

[0062] like Figure 2 to Figure 5 As shown, this embodiment provides a roundness correction device for a round tube, which mainly includes a bracket 21, a round tube correction component 41 and a balance component 61. A pendulum rod 31 is rotatably arranged on the bracket 21, and the round tube correction component 41 is arranged on the pendulum. One end of the rod 31, and the circular tube correction component 41 is located at the feeding end of the wire take-up machine to correct the roundness of the circular tube to be wound up. The force of the retracted round tube on the swing rod 31 is such that the round tube drawn out from the round tube correction assembly 41 is always tangent to the reel of the wire take-up machine. In the above-mentioned round tube roundness correction device, the round tube correction component 41 is located at the feeding end of the wire take-up machine 19, and can perform roundness correction on the round tube 51 to be wound up. The force of the...

Embodiment 2

[0076] This embodiment proposes another roundness correction device for a round tube, which is different from the first embodiment in that in the roundness correction device for a round tube in this embodiment, the round tube correction component 41 is a drawing module 49 . like Figure 6 to Figure 7 As shown, the drawing module 49 mainly includes a die base 491, a drawing die 494 and a fixing ring 496. The die base 491 is arranged on the mounting base 81, and a C-shaped groove 492 is opened on one side of the die base 491. The other side is provided with a circular tube lead-out hole 493 that communicates with the C-shaped groove 492. The drawing die 494 is arranged in the C-shaped groove 492. The drawing die 494 is provided with a conical correction hole 495. The tube lead-out hole 493 is coaxially arranged, and the small end of the conical correction hole 495 is adjacent to the round tube lead-out hole 493. The fixing ring 496 is arranged on the notch of the C-shaped groove...

Embodiment 3

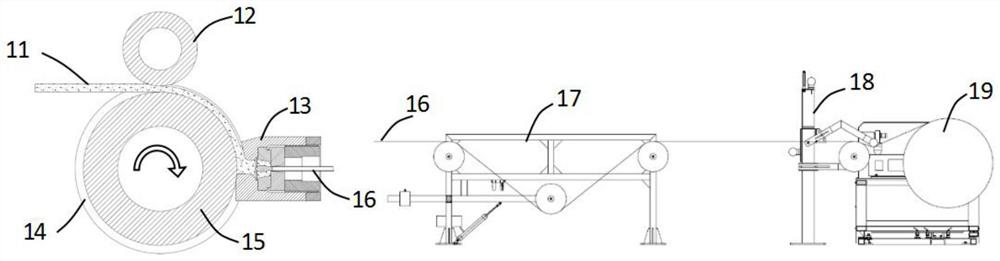

[0081] This embodiment proposes a system for continuously extruding and winding up and arranging a round tube, including a round tube forming device, a wire take-up machine 19 and the round tube roundness correction device as described in the first or second embodiment. The device is arranged between the round tube forming equipment and the wire take-up machine 19 . The round tube forming equipment can be the existing round tube extrusion forming equipment. The round tube continuous extrusion and winding system integrates the functions of round tube production, round tube correction and round tube winding, which is conducive to the realization of continuous extrusion and winding of high-precision round tubes, and the entire production line runs continuously. , improve production efficiency and production quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com