Positioning tool for injection molding ball valve

A technology for positioning tooling and ball valves, applied in the direction of coating, etc., can solve the problems of ball valve production quality, impact on ball valve control sealing effect, valve core pressure loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

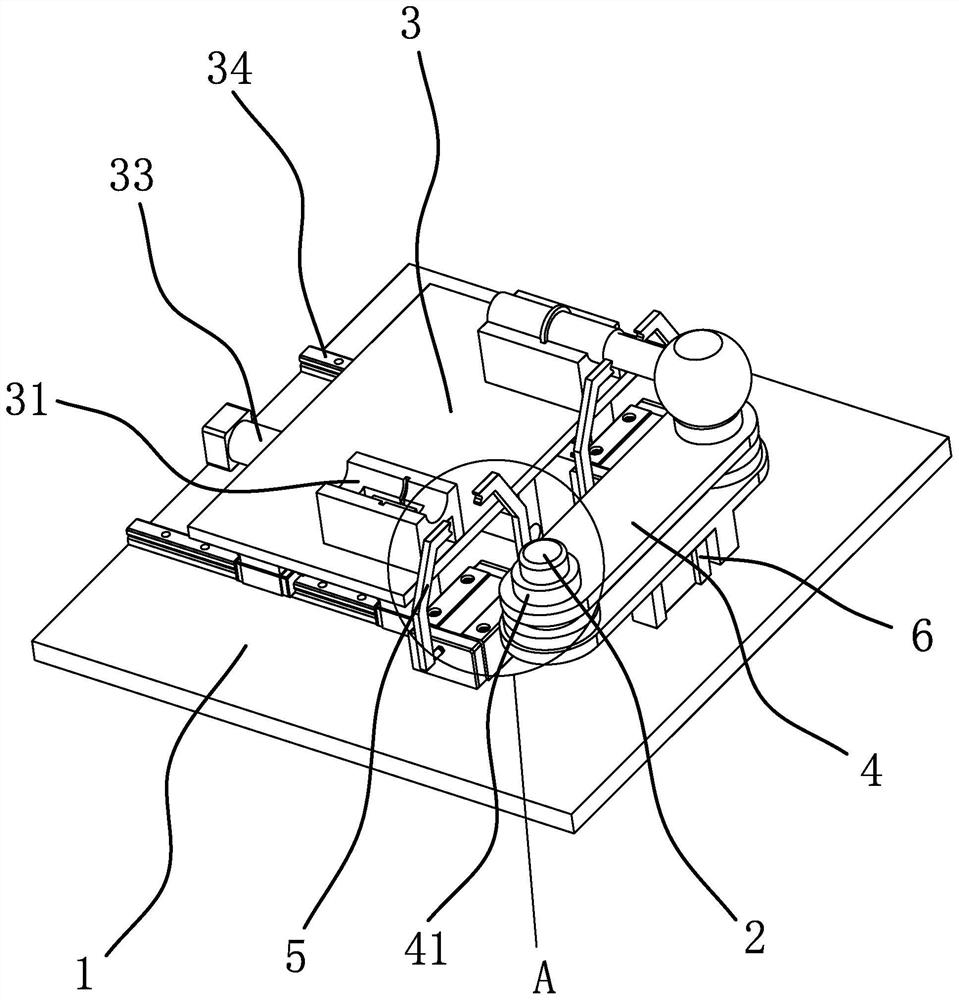

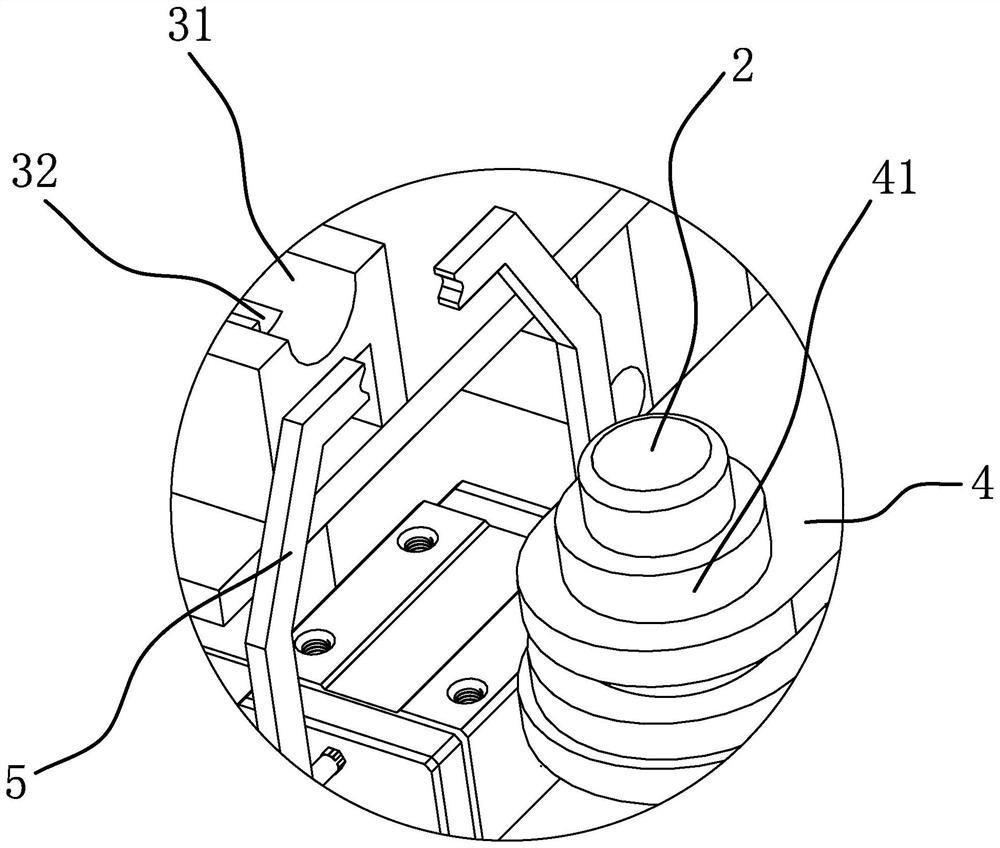

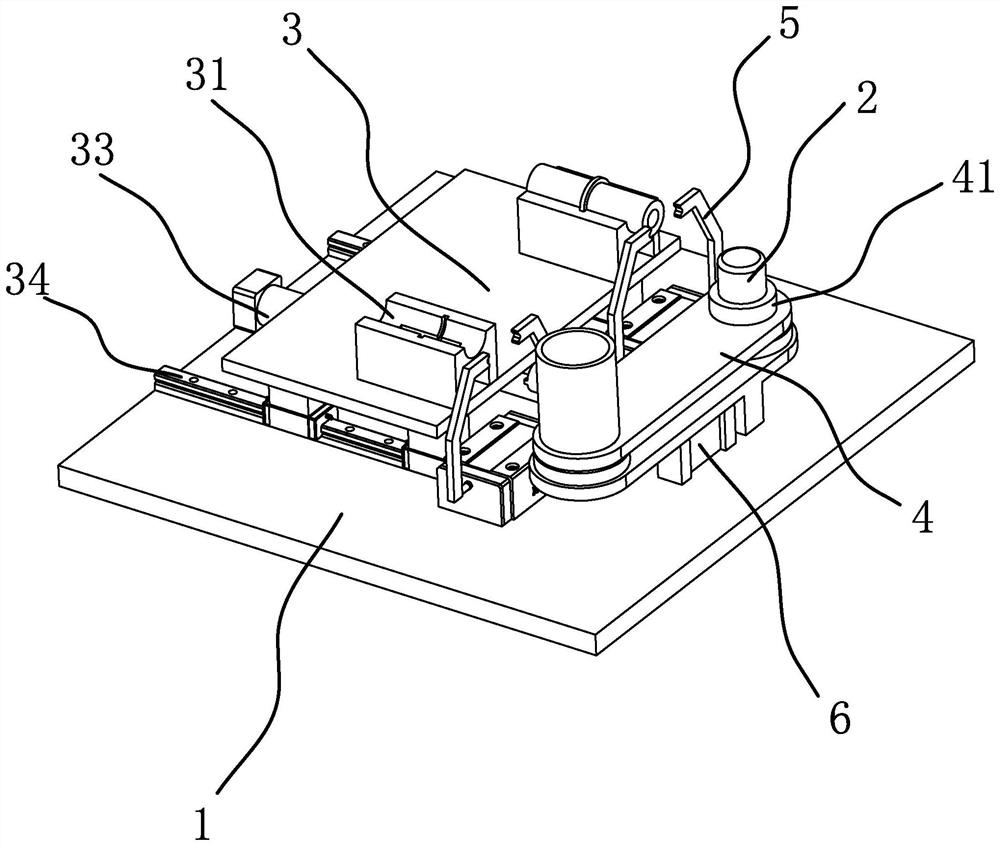

[0029] like Figure 1-3As shown, the positioning tooling of the injection ball valve includes a support platform 1, and the support platform 1 is connected with a positioning column 2 for positioning and matching with the inner hole of the valve core and a movable seat 3 for horizontally positioning the mold rod 8. The positioning column 2 is vertical The movable seat 3 can drive the mold rod to reciprocate along the axial direction of the mold rod toward the positioning column 2. The outer peripheral surface of the positioning column 2 is sleeved with a support sleeve 4 that can be positioned with the inner diameter of the formed ball valve port. Reciprocating vertically along the positioning column 2, the top surface of the support sleeve 4 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com