Thermal management system of electric automobile

A thermal management system and technology for electric vehicles, applied in the field of thermal management systems for electric vehicles, can solve problems such as interconnection and poor control of motor thermal management, and incomplete functional scenarios of thermal management systems, achieving low cost, easy control, and simple control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

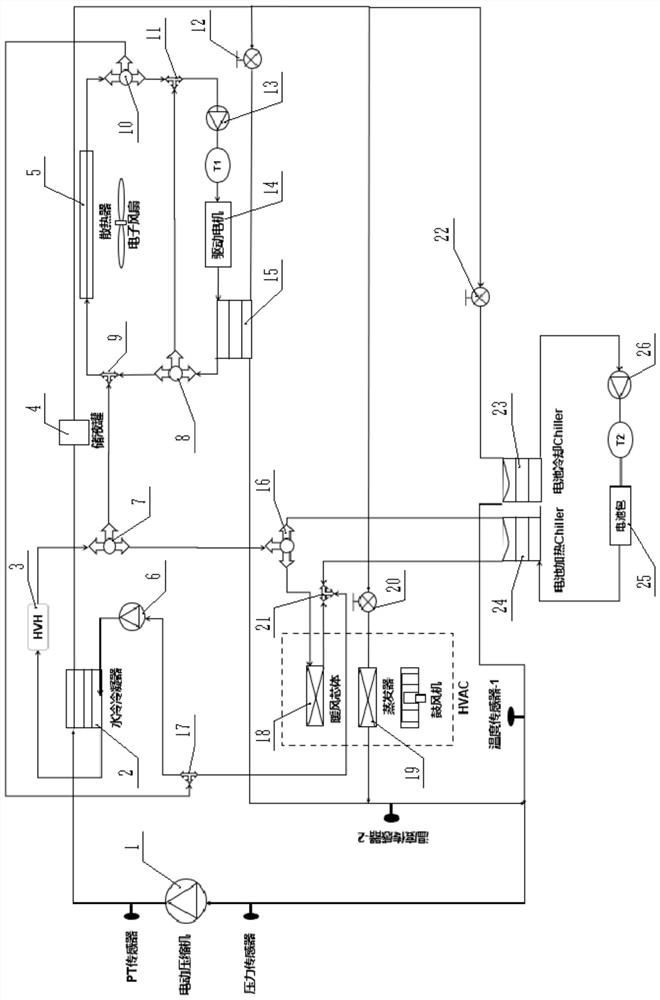

[0068] see figure 1 , is an electric vehicle thermal management system, including a refrigerant circuit, a battery circuit, a motor circuit, and a warm air circuit; the refrigerant circuit is provided with a refrigerant, and the battery circuit, the motor circuit, and the warm air circuit are all provided with cooling liquid;

[0069] The refrigerant circuit includes an electric compressor 1, a water-cooled condenser 2, a liquid storage tank 4, an evaporator 19, a battery cooling Chiller 23, a waste heat recovery device 15, a first EXV electronic expansion valve 12, a second EXV electronic expansion valve 20, and a third EXV Electronic expansion valve 22; the refrigerant circuit includes a first refrigerant circuit, a second refrigerant circuit, and a third refrigerant circuit;

[0070] The first refrigerant circuit includes an electric compressor 1, a water-cooled condenser 2, a liquid storage tank 4, a second EXV electronic expansion valve 20, and an evaporator 19, which are...

Embodiment 2

[0110] The difference between this embodiment and Embodiment 1 is that: on the basis of Embodiment 1, a high-voltage electric heater HVH3 is added to the heating air circuit, and the high-voltage electric heater HVH3 is installed on the water-cooled condenser 2 and the first three-way valve. On the connecting pipeline between 7, it is used to heat the coolant in the heating circuit.

[0111] The passenger compartment thermal management also includes a passenger compartment HVH compensated heating mode, and the battery thermal management also includes a battery HVH compensated heating mode.

[0112] The working mode of the HVH compensation heating mode of the passenger compartment is: open the first heating air circuit in the heating air circuit;

[0113] The cooling liquid circulates in the first warm air circuit; after the cooling liquid is compensated and heated by the high-voltage electric heater HVH3, the passenger compartment is heated by the warm air core 18.

[0114] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com