Method for manufacturing foldable glass by laser direct writing micro-nano structure

A technology of micro-nano structure and laser direct writing, which is applied in the field of new glass materials, can solve the problems of large manpower and material resources, time cost, and difficulty in foldability, and achieve the effect of ensuring the folding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

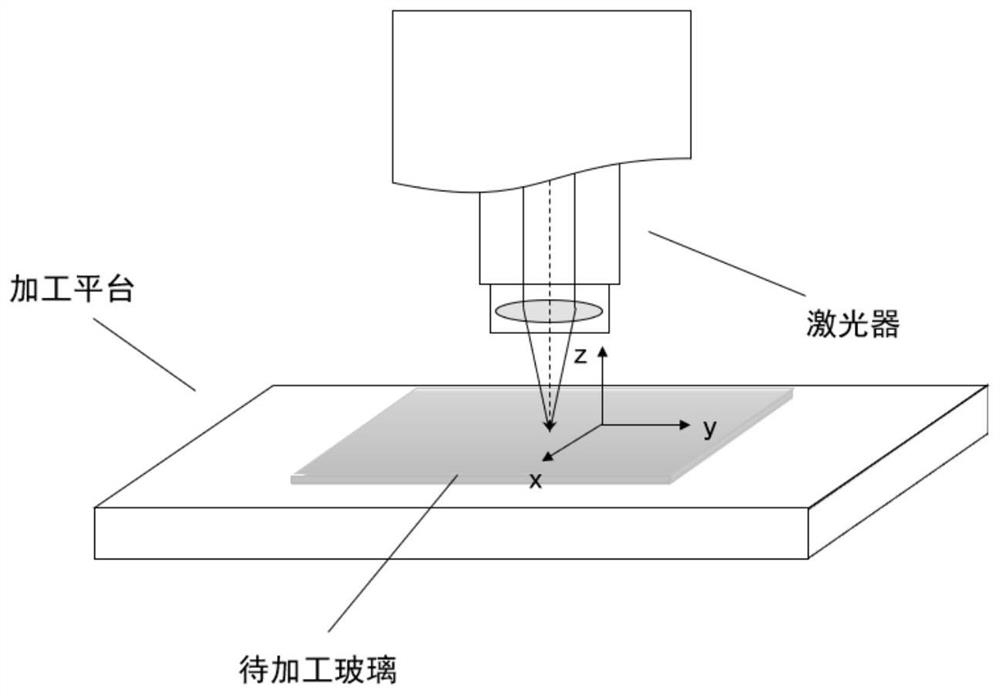

[0033] A method of laser direct writing micro-nano structure to fabricate foldable glass, such as figure 1 As shown, it is a schematic diagram of the process of laser micro-nano processing of foldable glass, which is prepared according to the following steps:

[0034] (1) Select the borosilicate glass to be processed, and its composition is 75% SiO 2 , 10% B 2 O 3 , 6%Na 2 O, 5% Al 2 O 3 , 2% BaO, 2% CaO, the size is 300mm×600mm, the thickness is 1mm, and the glass is completely cleaned;

[0035] (2) Place the glass on the three-dimensional sample stage;

[0036] (3) The wavelength of the ultraviolet laser for processing glass is 365nm, adjust the laser pulse width to 100ps, the pulse power to 10μJ, and adjust the objective lens and eyepiece to focus the laser on the starting position at the bottom of the glass;

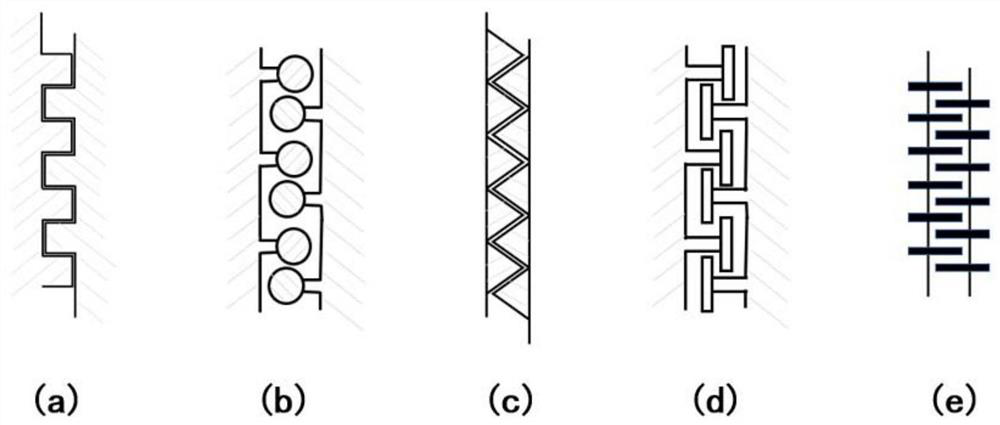

[0037] (4) Design a "rectangular" laser processing path in the control computer ( image 3 , a) and time, and locate the initial and end positions of laser p...

Embodiment 2

[0044] A method of laser direct writing micro-nano structure to fabricate foldable glass, such as figure 1 As shown, it is a schematic diagram of the process of laser micro-nano processing of foldable glass, which is prepared according to the following steps:

[0045] (1) Select the germanate glass to be processed, and its composition is 15% Na 2 O, 85% GeO 2, the size is 325mm×525mm, the thickness is 2mm, and the glass is completely cleaned;

[0046] (2) Place the glass on the three-dimensional sample stage;

[0047] (3) The visible laser wavelength for processing glass is 532nm, continuous laser, and the output power is 5W. Adjust the objective lens and eyepiece to make the laser focus on the starting position at the bottom of the glass;

[0048] (4) Design a "circular" laser processing path in the control computer ( image 3 , b) and time, and locate the initial and end positions of laser processing;

[0049] (5) Open the laser baffle, make the laser focus on the glass...

Embodiment 3

[0055] A method of laser direct writing micro-nano structure to fabricate foldable glass, such as figure 1 As shown, it is a schematic diagram of the process of laser micro-nano processing of foldable glass, which is prepared according to the following steps:

[0056] (1) Select the tellurite glass to be processed, and its composition is 75% TeO 2 , 10%Na 2 O, 8% PbF 2 , 7% Bi 2 O 3 , the size is 275mm×325mm, the thickness is 0.2mm, and the glass is completely cleaned;

[0057] (2) Place the glass on the three-dimensional sample stage;

[0058] (3) The wavelength of the near-infrared laser for processing glass is 1064 nm, the laser pulse width is adjusted to 150 fs, the pulse power is 25 μJ, and the objective lens and eyepiece are adjusted to focus the laser on the starting position at the bottom of the glass;

[0059] (4) Design a "triangle" laser processing path in the control computer ( image 3 , c) and time, and locate the initial and end positions of laser process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com