Water-based base layer treating agent capable of being stored at low temperature and preparation method of water-based base layer treating agent

A base treatment agent, water-based technology, applied in coatings, building insulation materials, building components, etc., can solve the problems of water-based base treatment agents that are not easy to store, and achieve the effect of good product uniformity and increased dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

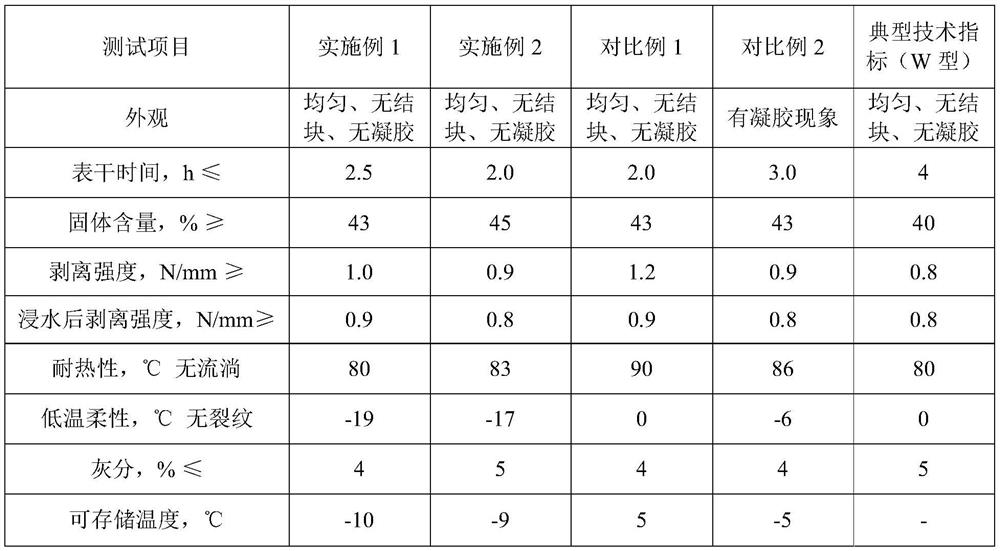

Examples

Embodiment 1

[0033] Add 55 parts of water, 1.5 parts of emulsifier, and 0.3 part of PH adjuster to a high-speed mixer, and at 65°C, with a rotating speed of 600rpm, stir for 30min to obtain soap solution; 21 parts of DOP plasticizer in ) state were emulsified by a colloid mill, the rotational speed of the colloid mill was 3000rpm, and the emulsification time was 5min to obtain emulsified DOP; the emulsified DOP was heated to 65 ℃, and 22.2 parts of Jingbo 70# petroleum asphalt was heated to 130 ℃, Then, the two are mixed by a colloid mill for re-emulsification, the rotation speed of the colloid mill is 4000 rpm, and the emulsification time is 10 minutes to prepare the base layer treatment agent.

Embodiment 2

[0035] Add 54 parts of water, 1 part of emulsifier, and 0.1 part of PH adjuster to a high-speed mixer, and at 65°C, with a rotating speed of 600rpm, stirring for 30min to obtain soap solution; 18 parts of DOP plasticizers in the state of ) were emulsified by a colloid mill, the rotational speed of the colloid mill was 3000rpm, and the emulsification time was 5min to obtain emulsified DOP; the emulsified DOP was heated to 65 ℃, and 26.9 parts of Jingbo 70# petroleum asphalt was heated to 130 ℃, Then, the two are mixed by a colloid mill for re-emulsification, the rotation speed of the colloid mill is 4000 rpm, and the emulsification time is 10 minutes to prepare the base layer treatment agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com