Green recyclable assembly type road intelligent pavement construction method and construction equipment

A construction equipment and prefabricated technology, applied in the field of green recyclable prefabricated road intelligent pavement construction methods and construction equipment, can solve problems such as environmental pollution, improve safety, reduce the possibility of falling, and improve environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

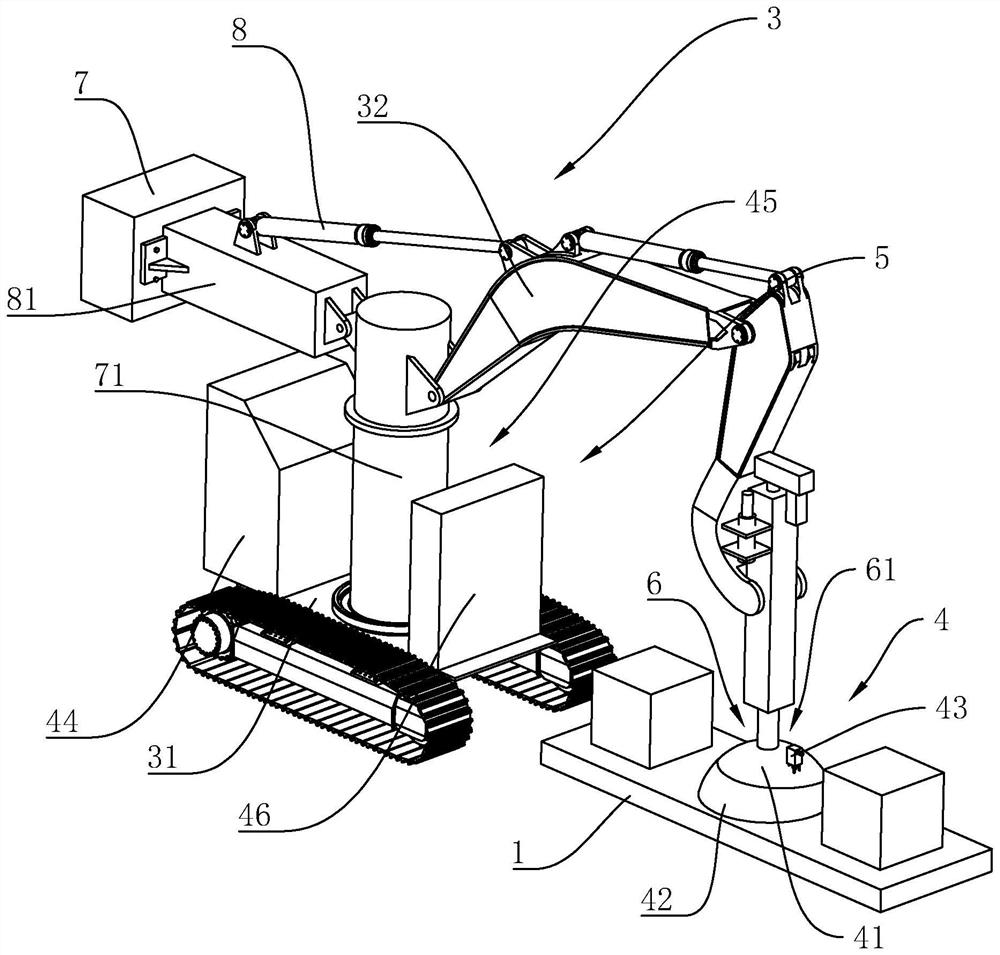

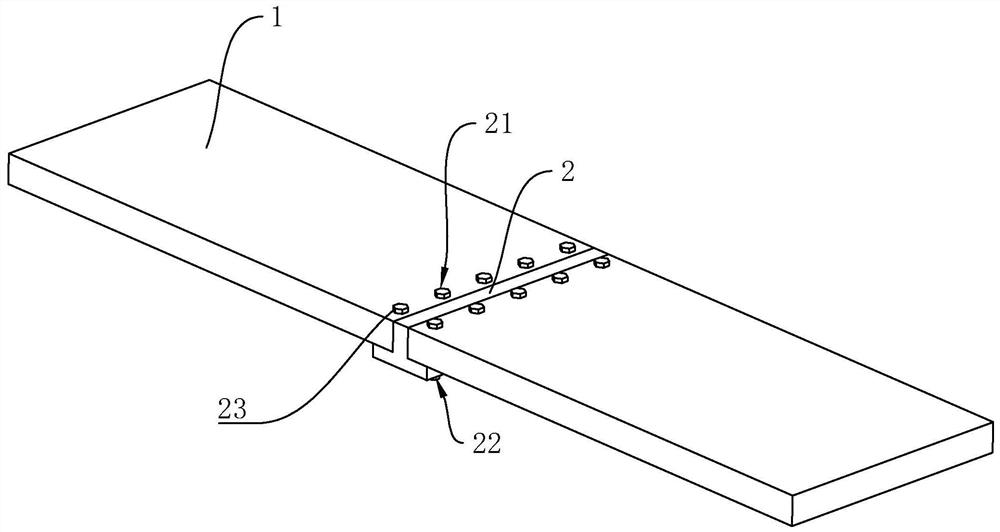

[0044] Attached to the following Figure 1-3 This application will be described in further detail.

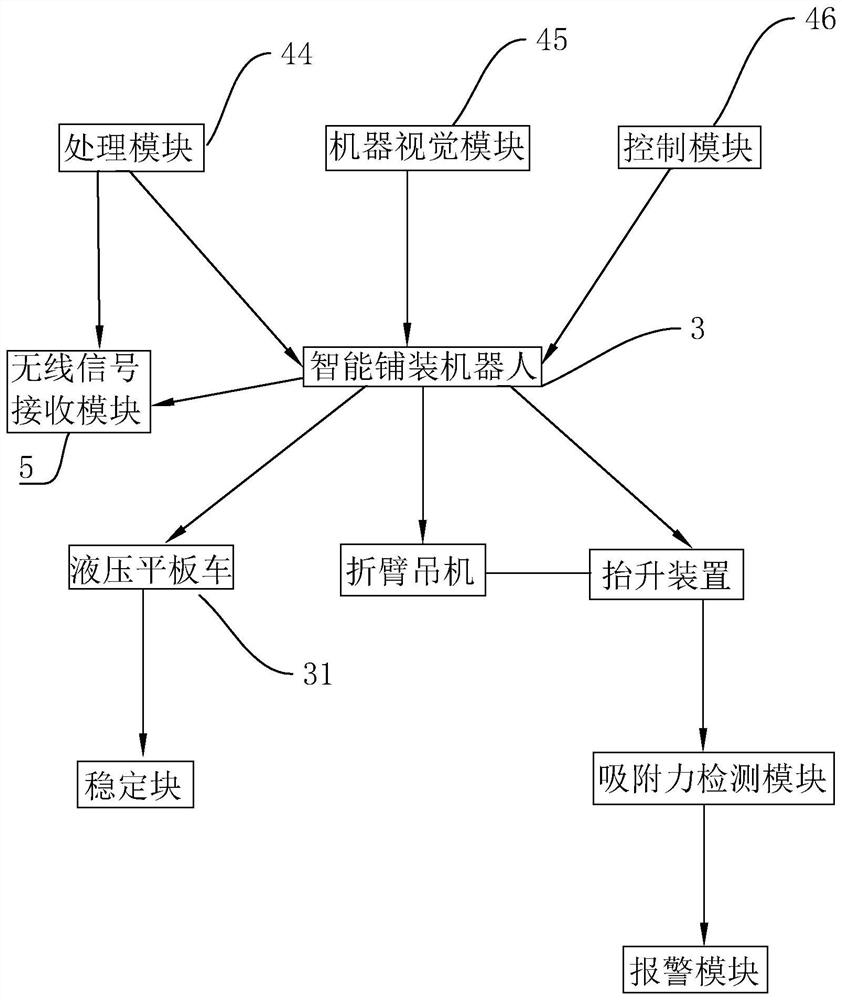

[0045] The embodiments of the present application disclose a green recyclable assembled road intelligent pavement construction method and construction equipment. refer to figure 1 , the green recyclable assembled road intelligent paving construction equipment includes an intelligent paving robot 3, and the intelligent paving robot 3 includes a processing module 44, a machine vision module 45, a control module 46 and a wireless signal receiving module 5;

[0046] The machine vision module 45 is installed on the intelligent paving robot 3. The machine vision module 45 can use a camera. The machine vision module 45 is used to monitor the laying position. The machine vision module 45 is connected to the processing module 44 for communication. The processing module 44 transmits the visual signal;

[0047] The processing module 44 is installed on the intelligent paving robot 3. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com