Pile casing device of full-slewing drilling machine

A technology of azimuth drilling rig and casing, which is applied to drill pipes, drill pipes, earthwork drilling, etc., can solve problems such as affecting the use of azimuth drilling rigs and increasing the pressure of azimuth drilling rigs to break the wall again, so as to increase the heat dissipation effect and improve the Practicality, the effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

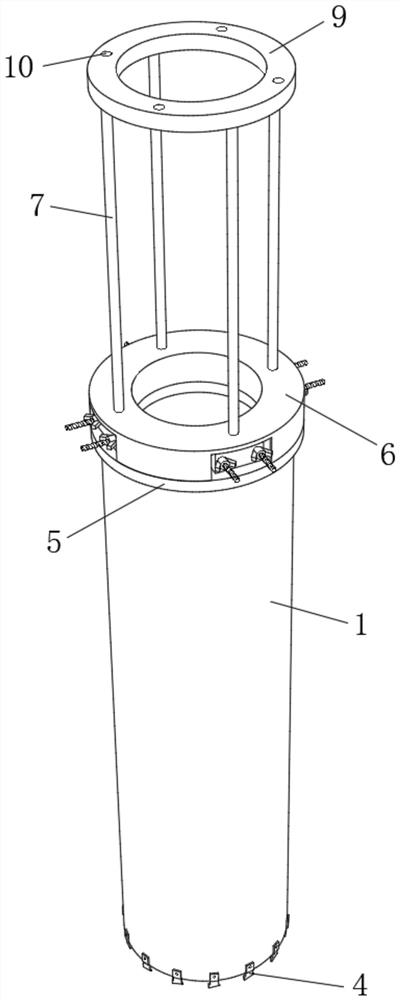

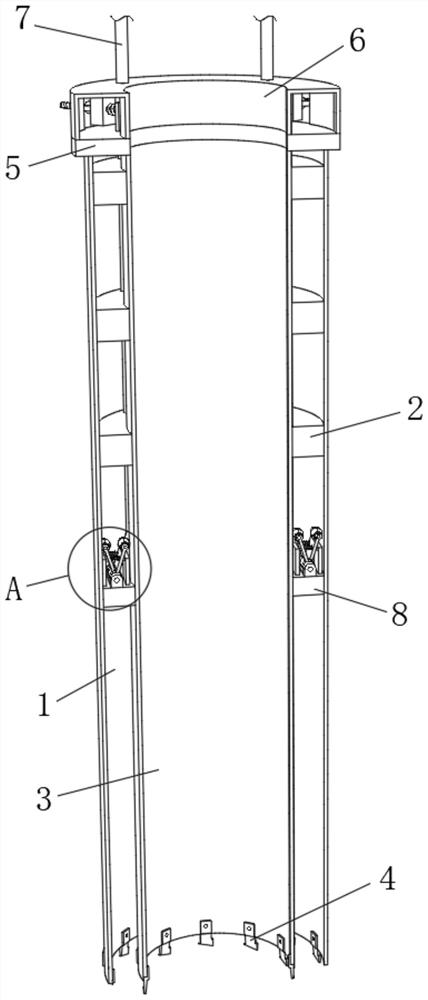

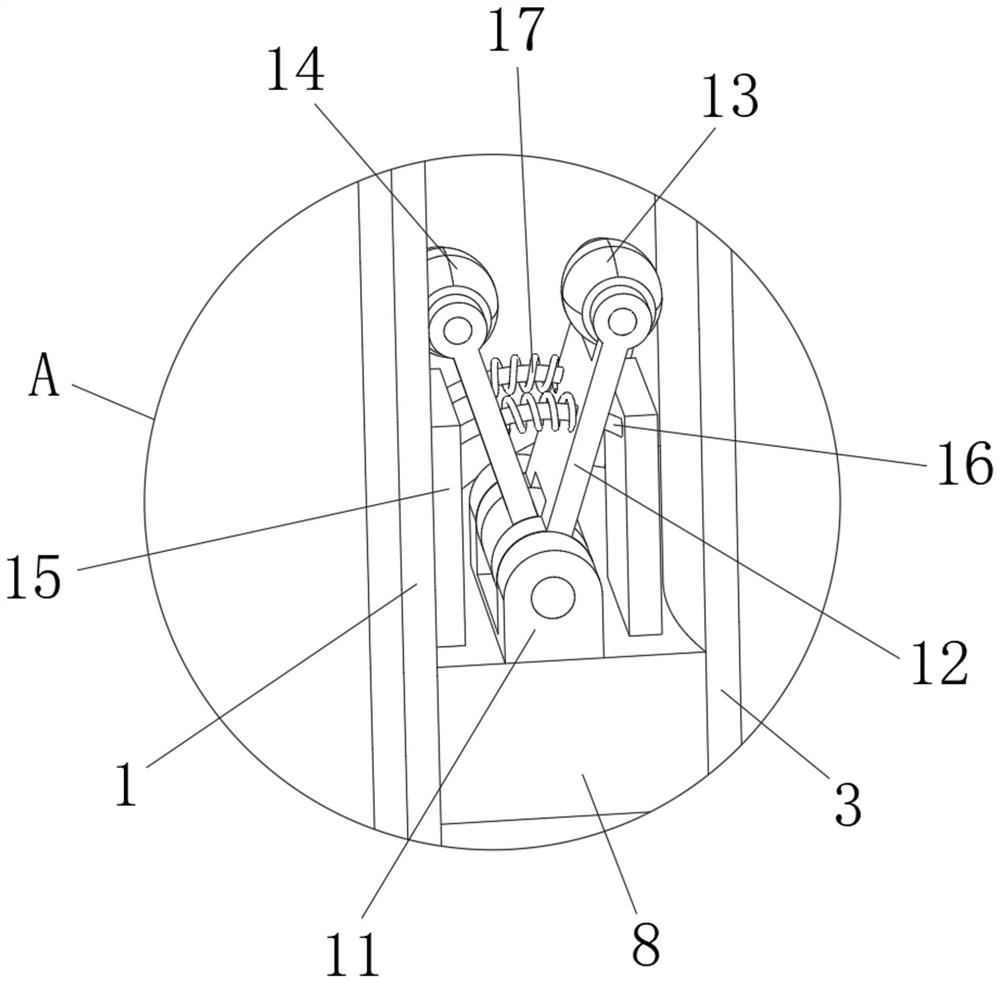

Embodiment 1

[0033] refer to Figure 1-Figure 5 , a cylinder protection device for an azimuth drilling rig, comprising an outer cylinder 1, a plurality of connecting rings 2 are fixed on the circumferential inner wall of the outer cylinder 1 by bolts, and the same inner cylinder is inserted between the circumferential inner walls of the connecting rings 2 3. The double-layer design of the outer cylinder 1 and the inner cylinder 3 can collect the crushed sand and soil in the interlayer between the outer cylinder 1 and the inner cylinder 3, so as to avoid the damage of the outer cylinder 1 and the inner cylinder 3. The rotation will compact the broken sand, gravel and soil against the cave wall, reducing the pressure of the azimuth drilling rig to break the wall again, and improving the practicability of the azimuth drilling rig. The bottom of the outer cylinder 1 and the inner cylinder 3 are provided with multiple The design of the drill 4 and the double-layer drill 4 can increase the rotat...

Embodiment 2

[0037] refer to Figure 6-Figure 7 , a cylinder protection device for an azimuth drilling rig, comprising a plurality of heat dissipation holes 26 on the circumferential outer wall of the outer cylinder body 1, an annular inclined surface cover 27 fixed on the circumferential outer wall of the outer cylindrical body 1 by bolts, and the heat dissipation holes 26 are located in the annular inclined surface cover. Inside 27, the heat dissipation hole 26 can be partitioned by the annular inclined surface cover 27 to prevent the entry of rainwater and dust, which increases the use of the azimuth drilling rig. A heat dissipation ring 29 is fixed on one side by bolts, and the heat dissipation ring 29 is in contact with the circumferential inner wall of the outer cylinder 1. The heat generated by the friction between the outer cylinder 1 and the inner cylinder 3 and the sand and stone can be conducted to the outer cylinder 1 and the inner cylinder 3 through the heat conduction ring 28....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com