Thin film strain gauge bridge circuit based on flexible circuit board on high-rigidity force measuring knife handle

A flexible circuit board, bridge circuit technology, applied in the direction of measuring force, measuring device, measuring/indicating equipment, etc., can solve the problems of difficult to control thin film, resistance error, low resistance value, etc., to improve circuit stability, reduce Small wire length, reduced impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention are further described below with reference to the accompanying drawings.

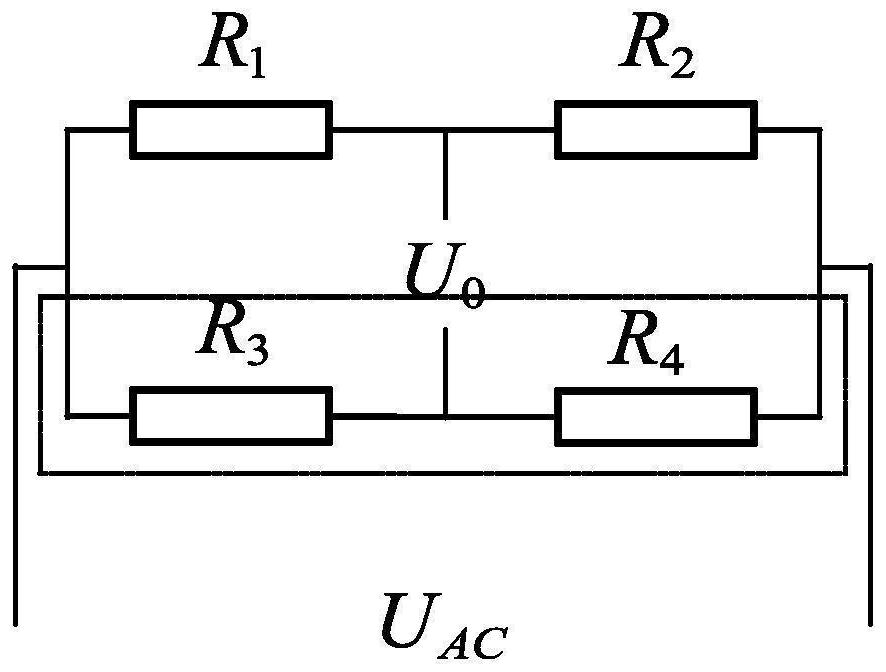

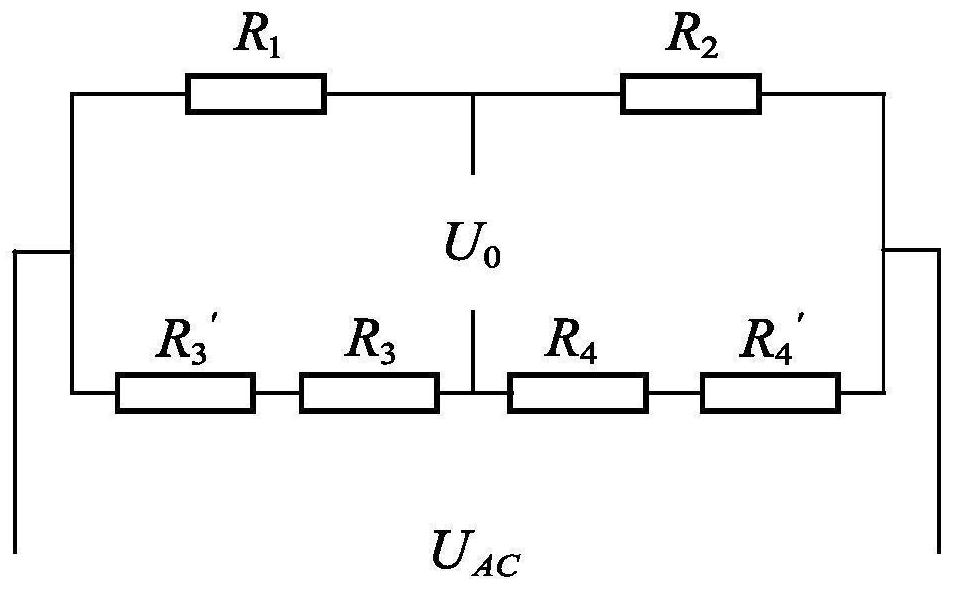

[0023] like Figure 4 As shown in the figure, a thin-film strain gauge bridge circuit based on a flexible circuit board on a high-rigidity force measuring tool handle of the present invention adopts a structure of parallel registration of multi-stage resistances, including two thin-film strain resistances R 1 , R 2 and four registration resistors R 3 , R 4 , R 5 , R 6 ;Registration resistor R 4 , R 5 , R 6 After parallel connection with the registration resistor R 3 series, and then with the thin film strain resistance R in series 1 and R 2 in parallel;

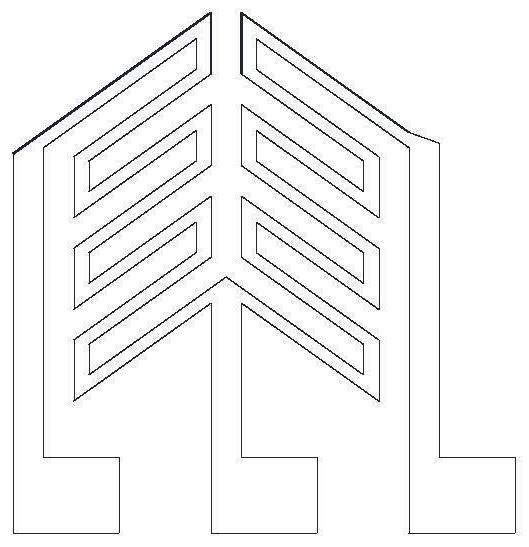

[0024] The thin film strain resistance R 1 , R 2 It is deposited on the surface of the tool handle by means of thin film growth, and the registration resistance R 3 , R 4 , R 5 , R 6 Soldered on the flexible circuit board, and connected to the subsequent circuit through the flexible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com