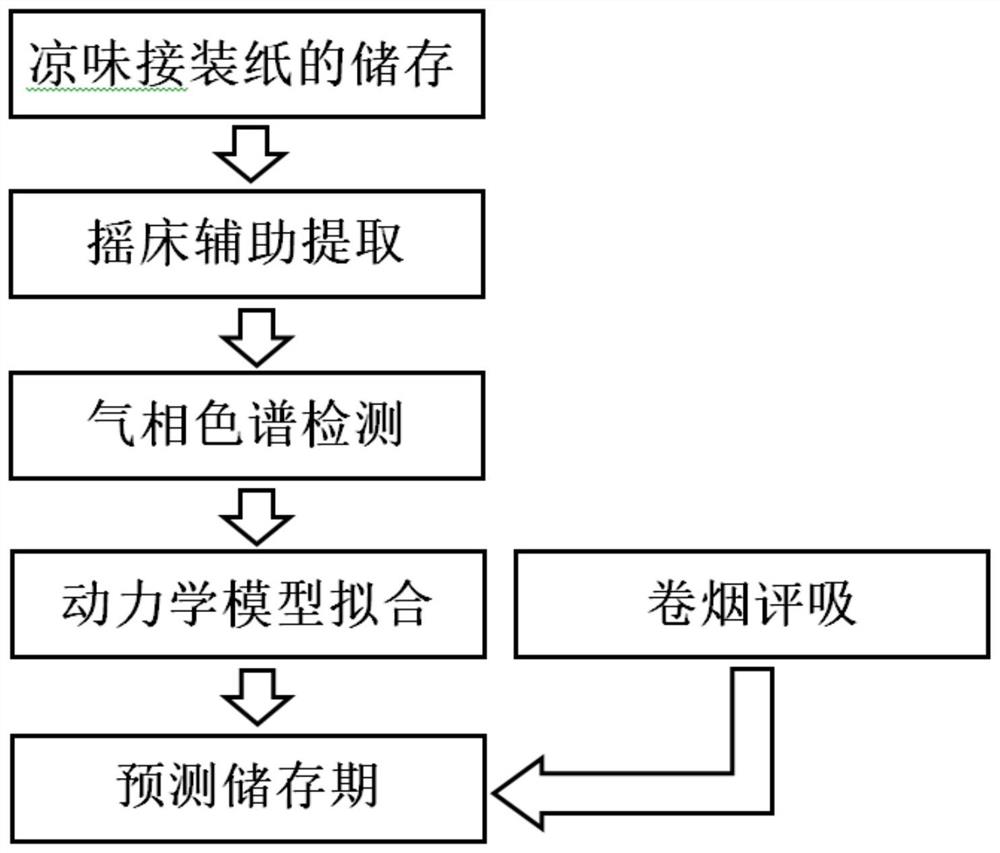

Method for predicting storage life of cool tipping paper based on attenuation kinetics

A tipping paper and storage period technology, applied in the field of tobacco volatile substance analysis, can solve problems such as loss of flavor of cooling agent, and achieve the effects of improving cigarette quality, good storage and use, and improving cigarette taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Storage of cooling tipping paper sample 1: under the condition of humidity of 60%, the cooling tipping paper sample 1 was stored in the temperature environment of 0°C, 20°C and 35°C, respectively, and stored at 0, 20°C and 35°C, respectively. Samples were taken at 5, 10, 20, 40, 60, 90 and 130 days for subsequent analysis.

[0046] (2) Extraction of cooling agent: The tipping paper sample 1 was pulverized into pieces of 5mm×5mm with a shredder, and 1g of tipping paper sample 1 piece was weighed, placed in a 50mL conical flask with a stopper, and 25mL of ethanol was added. The shaker was shaken for 25 min at a temperature of 30 °C and a rotational speed of 160 r / min.

[0047] (3) Detection of cooling agent: take the extract filter membrane in step (2), and the filtrate is detected and analyzed by gas chromatograph. The gas chromatography conditions are: HP-5MS column, the size of the column is 30m×250μm×0.25μm; the inlet temperature: 250°C; the detector temperature:...

Embodiment 2

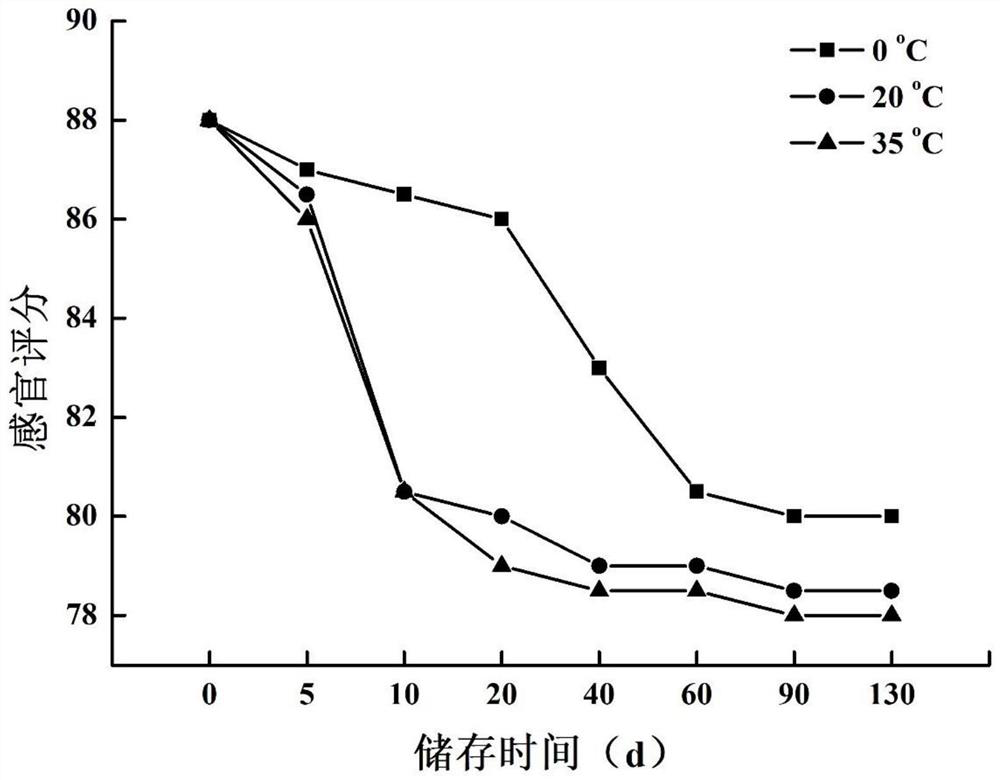

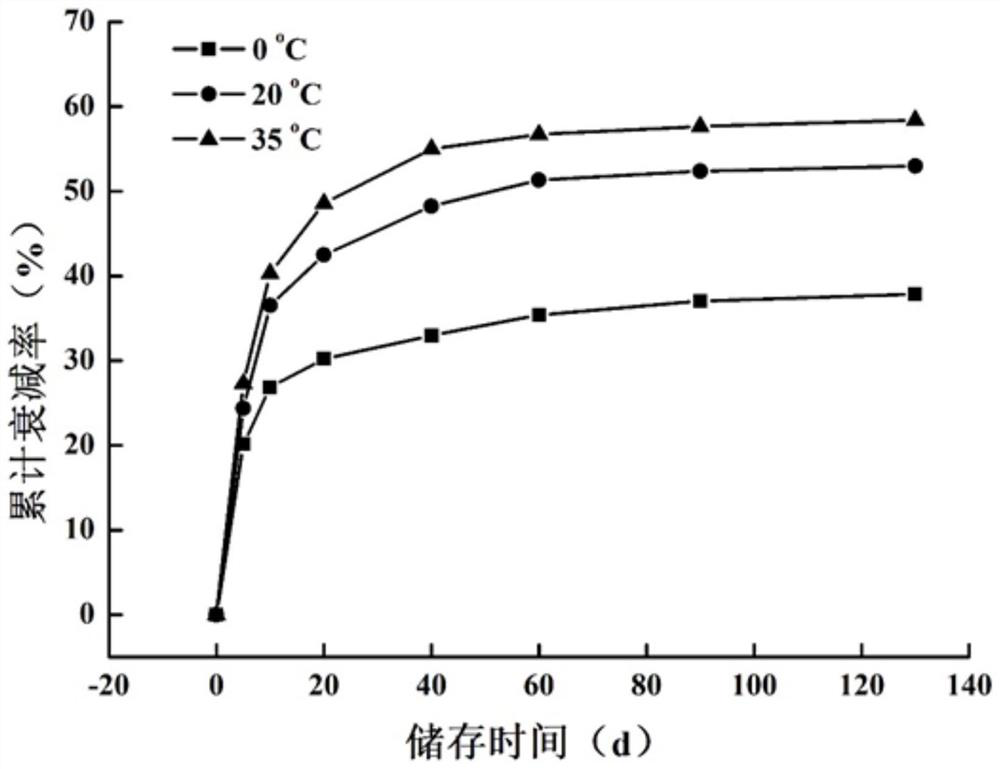

[0070] The difference from Example 1 is that the extraction sample is cooling tipping paper 2, and the extraction object is L-menthol. The pretreatment steps are as in Example 1, and the tipping paper samples 2 stored at different temperatures are rolled, and the evaluation results of the cigarettes made are as shown in Table 4 and Table 4. Figure 4 shown. by Table 4 and Figure 4 It can be seen that the sensory score of cigarettes made of 2 rolls of tipping paper stored for 0 days is better. When smoking, with the increase of storage time, the sensory score gradually decreases, and the coolness gradually weakens. The storage temperature is 0, 20, 35 The sensory scores of tipping paper sample 2 at ℃ decreased significantly after being stored for 20, 5, and 5 days, respectively. Therefore, the average value of (-)-menthone content in tipping paper sample 2 at 3 different storage temperatures was selected to be 2.06 mg / g is the critical value, if the content of L-menthol in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com