A method of producing aluminum foil lining paper

A technology of lining paper and aluminum foil, which is applied in papermaking, packaging paper, paper coating, etc., can solve the problems that the lining paper cannot keep the fragrance for a long time, and the lining paper does not improve the cigarette alcohol, so as to prevent outward emission, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

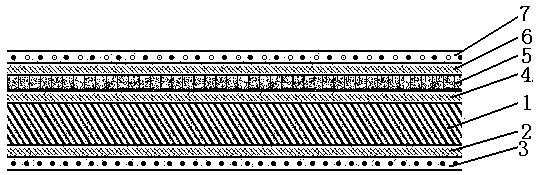

[0036] Such as figure 1 Shown, produce a kind of aluminum foil lining paper, comprise the following steps.

[0037] ⑴Use the backing paper as the base layer 1, randomly set one surface as the outer surface, and set the other side as the inner surface.

[0038] (2) Coating a layer of viscose on the outer surface as the first viscose layer 2 .

[0039] (3) Then coat a layer of aluminum foil on the outside of the first adhesive layer 2 as the aluminum foil layer 3; the aluminum foil layer 3 is used as the outermost layer.

[0040] (4) Then apply a layer of viscose on the inner surface as the second viscose layer 4.

[0041] (5) Coating a layer of cigarette film slurry on the outside of the second adhesive layer 4 as the cigarette film layer 5 .

[0042] (6) Coating a layer of viscose on the outside of the cigarette film layer 5 as the third viscose layer 6 .

[0043] (7) Finally, a layer of microporous aluminum foil is coated on the outside of the third adhesive layer 6 as th...

Embodiment 2

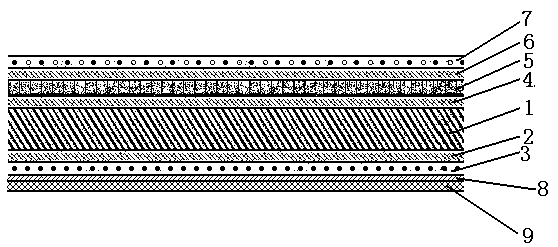

[0046] Such as figure 2 As shown, further, on the basis of Example 1, a layer of printing layer 8 is coated outside the aluminum foil layer 7; outer layer.

[0047] In this way, the aluminum foil lining paper produced by the present invention that can protect the outer surface of the aluminum foil is completed.

Embodiment 3

[0049] To prepare viscose, the viscose used in the present invention is special viscose for aluminum base. In this embodiment, the special viscose for aluminum base is produced according to the following three schemes. But it is not limited to these three schemes in actual production.

[0050] Option 1: Add 10kg of oxidized starch to 35kg of deionized water and mix evenly, then add 1kg of medical hydrogen peroxide and mix evenly, then add 1kg of tobacco seed oil and mix evenly, then add 3kg of konjac gum and mix evenly, then heat in a 76°C water bath and continue Stir evenly for 25 minutes, then cool down to 55°C and let stand for 45 hours to remove air bubbles, then cool to obtain aluminum-based adhesive.

[0051]Solution 2: Add 20kg of oxidized starch to 70kg of deionized water and mix evenly, then add 2kg of hydrogen peroxide and mix evenly, then add 2kg of tobacco seed oil and mix evenly, then add 4kg of konjac gum and mix evenly, then heat in a 78°C water bath and continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com