Low-water-distribution developing plate processor

A technology of plate processor and water distribution, which is applied in photoplate-making process exposure devices, microlithography exposure equipment, photosensitive material processing, etc. The effect of purification and a small amount of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

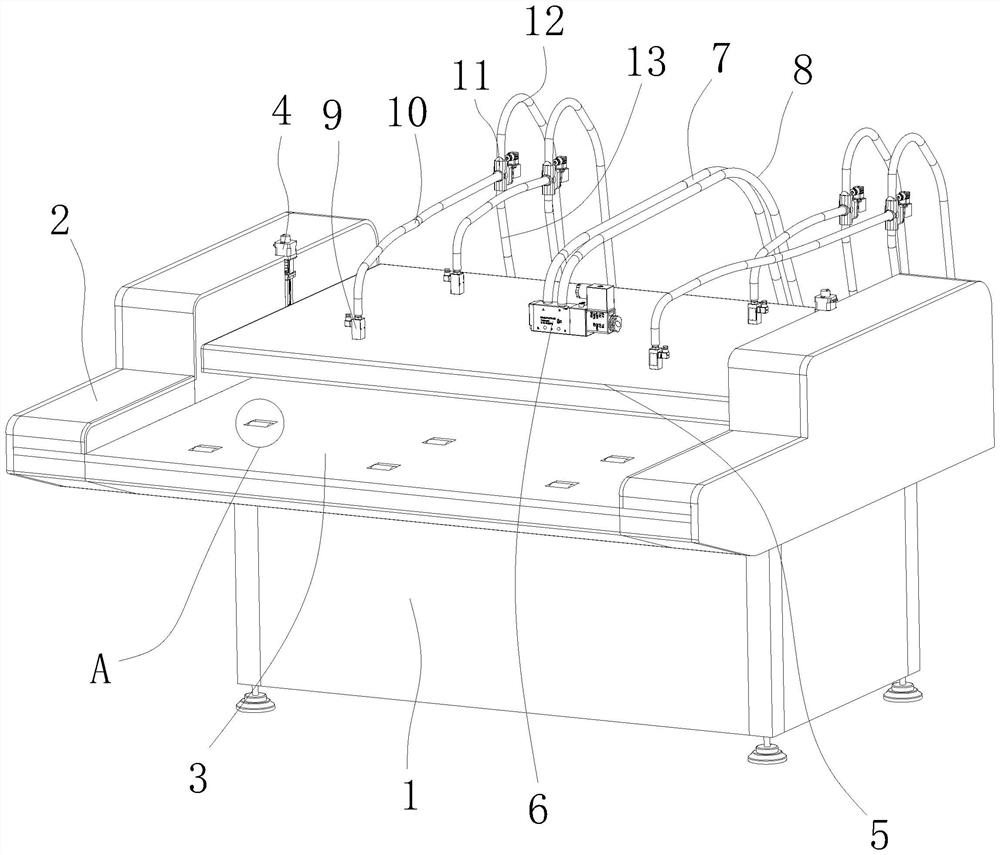

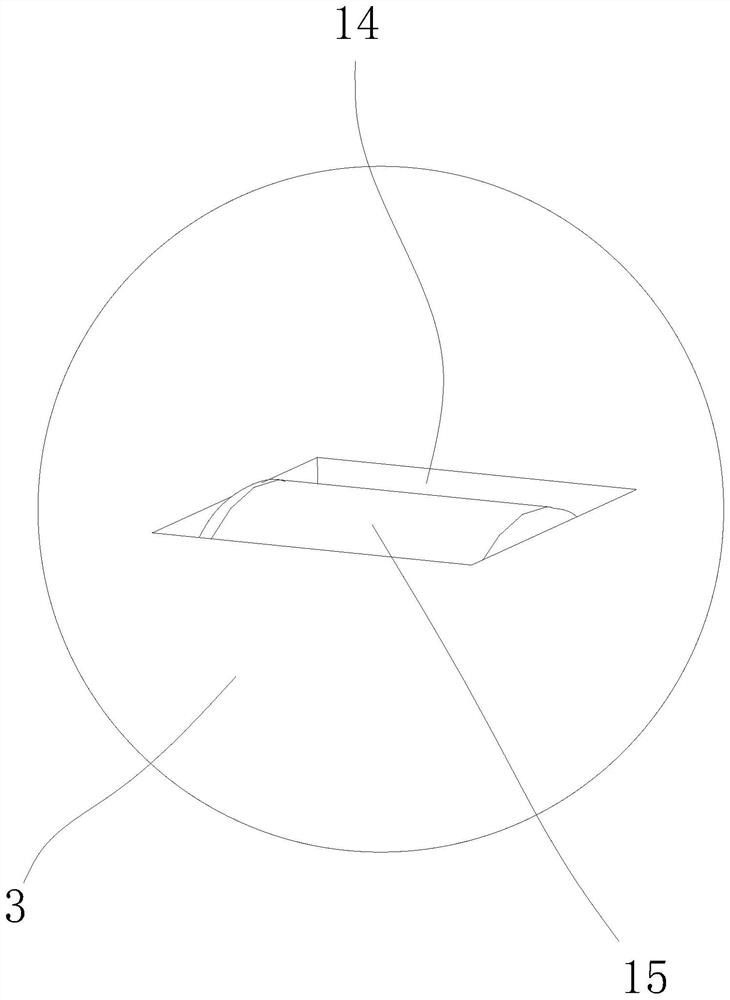

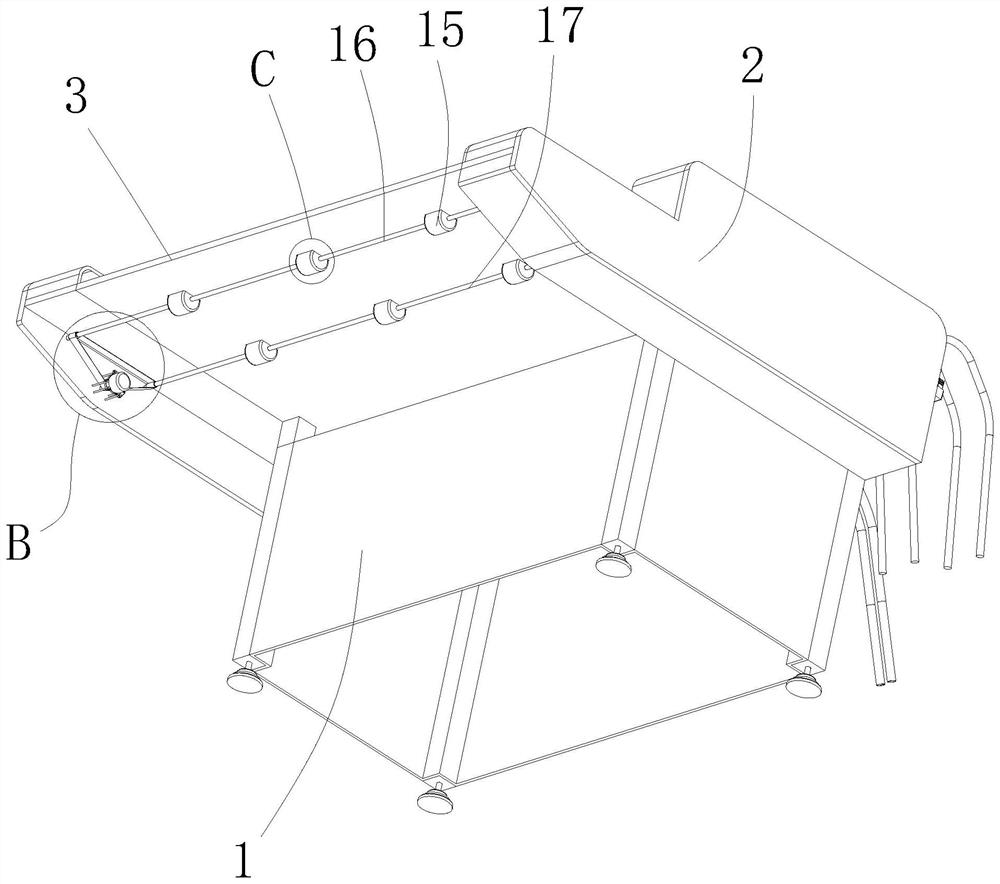

[0034] The low water distribution processor, such as figure 1 As shown, it includes a base 1 , two racks 2 fixedly connected above the base 1 , and a workbench 3 fixedly connected between the two racks 2 .

[0035] The top surface of the base 1 is fixedly connected with an ultrasonic generator which is in conflict with the bottom surface of the worktable 3 .

[0036] like figure 1 , 9 As shown in Fig. 11, a lifter 4 is provided in the frame 2, a groove is provided on the side of the frame 2 facing each other, the lifter 4 is fixedly connected in the groove, and the lifter 4 includes a rail that is fixedly connected in the groove. 29. The second motor 28 fixedly connected to the upper end of the track 29, the lead screw 30 that is fixedly connected to the rotating shaft of the second motor 28 and penetrates into the track 29, and the nut block threadedly connected to the outside of the lead screw 30 and slidably connected to the track 29 31.

[0037] A cover body 5 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com