Water-soluble films and water-soluble unit dose articles made therefrom

A water-soluble film, water-soluble polymer technology, applied in detergent materials, detergent compositions, chemical instruments and methods, etc., can solve problems such as incomplete film dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

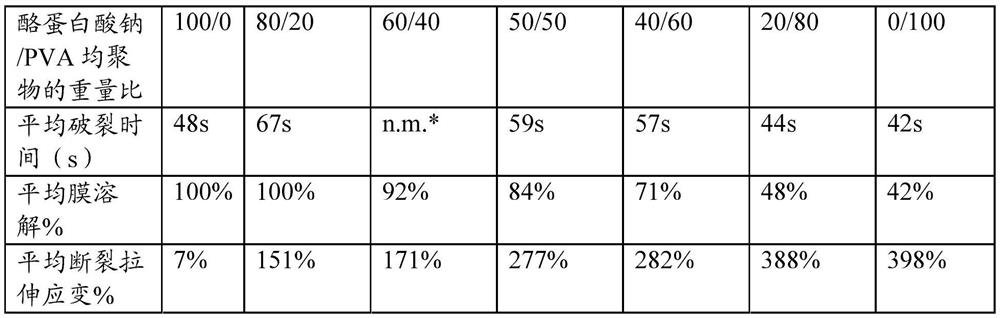

[0079] testing method :

[0080] 1. Membrane disintegration time :

[0081] According to the MSTM-205 disintegration protocol, the cold water film disintegration characteristics of different sodium caseinate / polyvinyl alcohol homopolymer water-soluble films were determined in demineralized water at 10°C. Within this test, the average membrane rupture time (in seconds) has been recorded for 3 replicates.

[0082] 2. Membrane dissolution time :

[0083] The cold water solubility characteristics of different sodium caseinate / polyvinyl alcohol homopolymer based water-soluble films were determined in demineralized water at 20°C by Monosol using a dissolution chamber according to MSTM-119 Standard Test Method for Residues. In this test, the average % dissolved film after 10 minutes of immersion in water has been recorded for 3 replicates of the film.

[0084] 3. Tensile strain at break % :

[0085] The water soluble film test samples were analyzed for % tensile strain at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com