Iron-based alloy with high corrosion resistance and wear resistance

An iron-based alloy and alloy technology, which is applied in the field of alloys with high corrosion resistance and high wear resistance, can solve problems such as corrosion of cast iron brakes and reduced braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] By means of one or more of the various aspects, embodiments and / or specific features or sub-assemblies of the present disclosure, one or more of the advantages as specifically described above and pointed out below are intended.

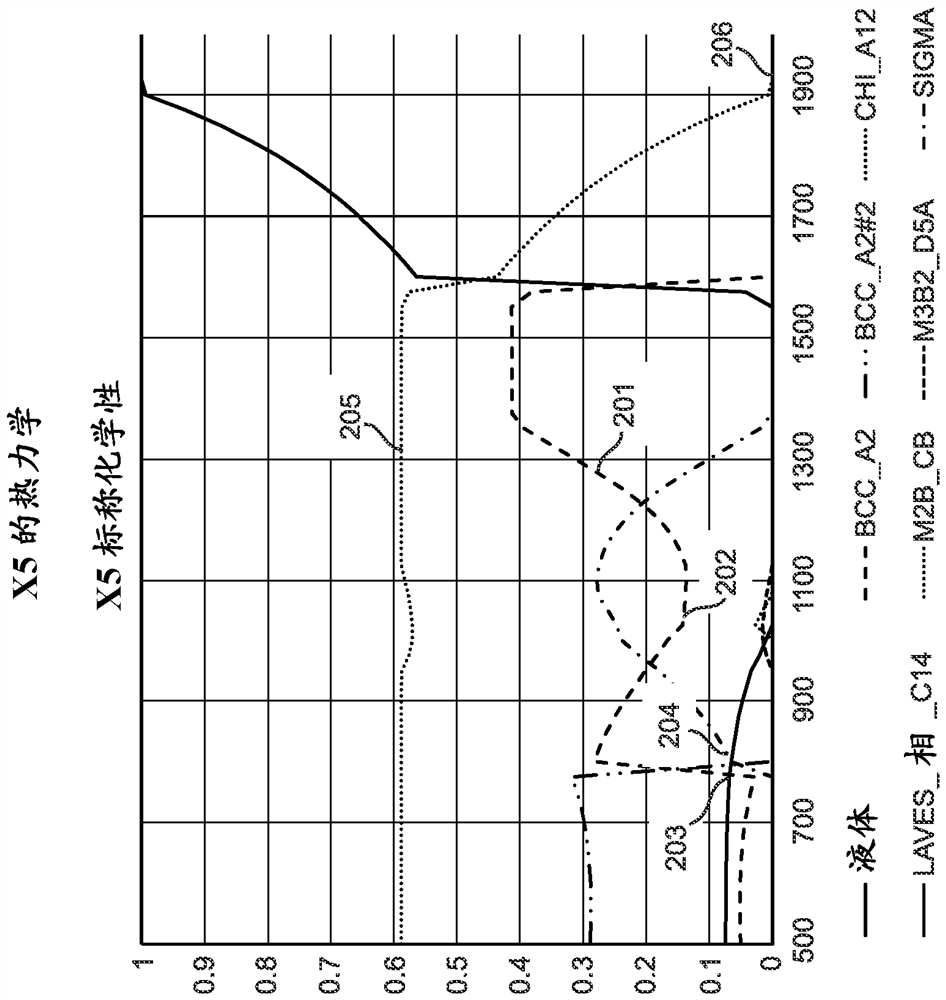

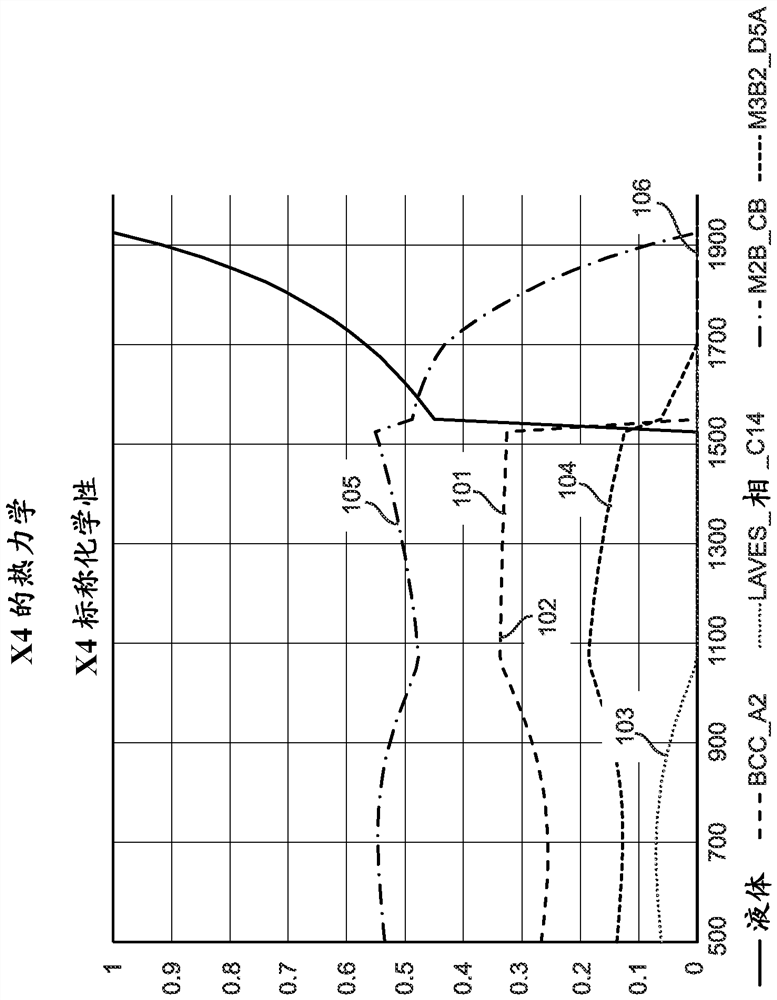

[0018] thermodynamics

[0019] In example embodiments of the present disclosure, alloys may be adequately described by equilibrium or near-equilibrium thermodynamic parameters, such as figure 1 and 2 illustrated. One way to predict the corrosion performance of ferroalloys is to use PREN calculated according to the following equation (1):

[0020] PREN = Cr+3.3 * (Mo+0.5 * W)+16 * N (1),

[0021] The element value is expressed in weight percentage.

[0022] In single phase materials, such as most ferritic stainless steels, PREN is applied to the bulk alloy composition. However, because the alloys in the present disclosure can include multiple phases, the PREN value is calculated based on the equilibrium thermodynamic conditions of the matri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com