A hydraulic free piston engine

A piston engine and hydraulic technology, which is applied in the power and hydraulic fields, can solve problems such as excessive coaxiality requirements, constraints, and poor processing technology of piston components, so as to improve the compactness of the structure, simplify the structure, and reduce the technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

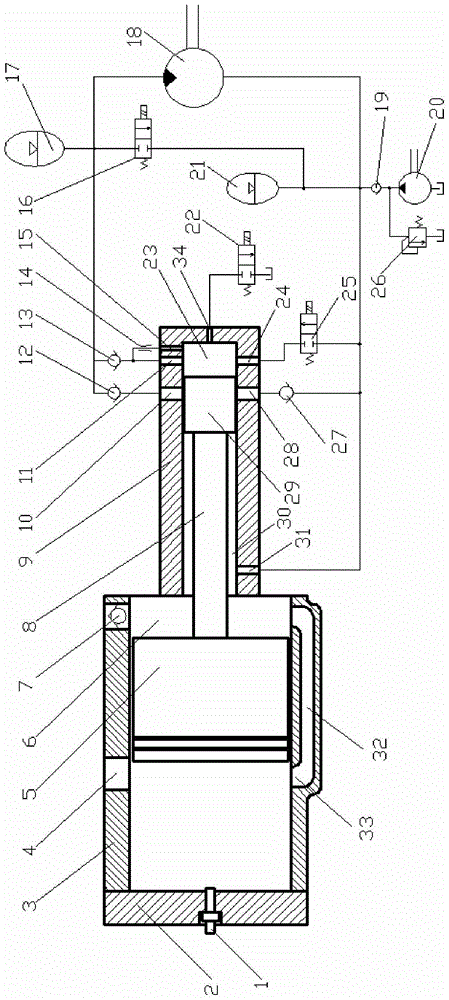

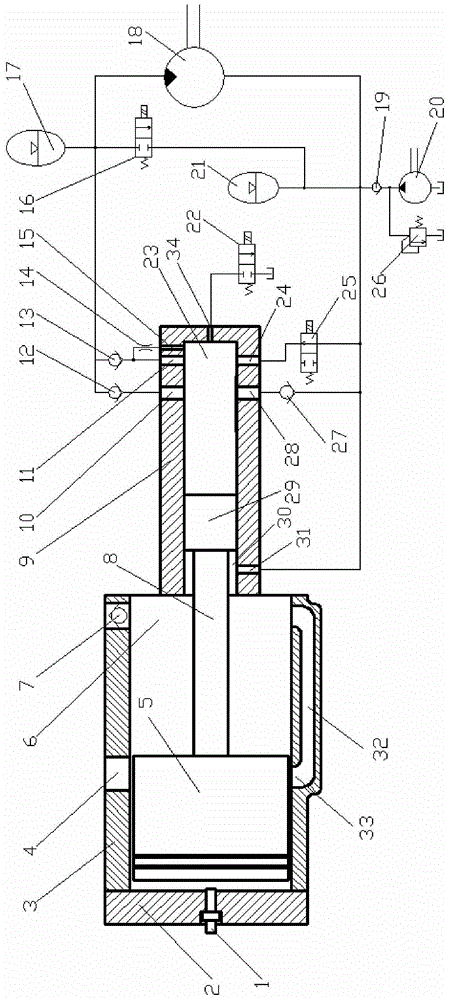

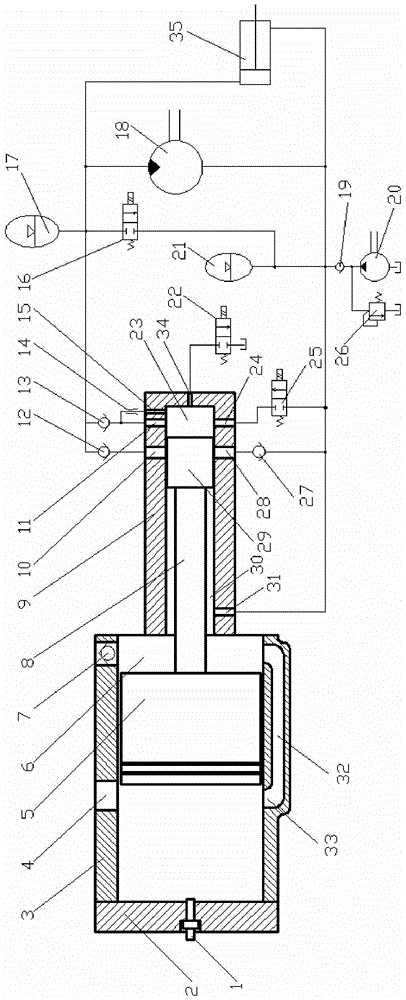

[0020] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. However, the embodiments of the present invention are not limited to this.

[0021] Generally, the low pressure end of the hydraulic system is atmospheric pressure, or in order to ensure that the pump piston does not appear cavitation when sucking oil, the low pressure end pressure is increased to 0.5 MPa, and the output high pressure oil pressure is more than ten MPa or tens of MPa. The basic idea of the technical solution of the present invention is to increase the pressure at the low pressure end of the hydraulic free piston engine from the traditional atmospheric pressure or 0.5MPa pressure to a pressure sufficient to drive the piston assembly to complete the compression stroke, such as a higher pressure of 5MPa. This pressure is sufficient to push the piston assembly to complete the compression stroke of the power piston. When the piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com